The Cummins 4359433 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the operation of commercial trucks. This ECM is integral to the truck’s engine management system, ensuring efficient performance and reliable operation. Its role in the vehicle’s overall functionality underscores the importance of understanding its capabilities and integration within the truck’s systems 1.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that controls various functions within a vehicle. It processes data from multiple sensors and adjusts engine parameters to optimize performance, fuel efficiency, and emissions 3. In the context of truck operations, ECMs are vital for integrating and coordinating the complex systems that power and regulate these vehicles. They facilitate real-time adjustments and diagnostics, enhancing the overall efficiency and reliability of the truck.

Purpose of the Cummins 4359433 ECM

The Cummins 4359433 ECM is specifically designed to manage the engine’s operations in commercial trucks. It oversees critical functions such as fuel injection, ignition timing, and emissions control. By continuously monitoring and adjusting these parameters, the ECM ensures that the engine operates within optimal performance ranges, contributing to both efficiency and longevity of the vehicle 4.

Key Features of the Cummins 4359433 ECM

The Cummins 4359433 ECM boasts several key features that enhance its functionality. These include advanced processing capabilities that allow for quick data analysis and decision-making. It also offers robust connectivity options, enabling seamless integration with other vehicle systems and diagnostic tools. Additionally, the ECM includes comprehensive diagnostic functions that help in identifying and addressing potential issues before they escalate 2.

Benefits of Using the Cummins 4359433 ECM

Incorporating the Cummins 4359433 ECM into a truck’s system offers numerous advantages. It contributes to improved fuel efficiency by optimizing engine performance based on real-time data. This results in cost savings and reduced environmental impact. Furthermore, the ECM enhances overall truck performance, ensuring smooth and reliable operation. Its diagnostic capabilities also aid in maintaining the vehicle, leading to increased reliability and reduced downtime 3.

Installation and Integration

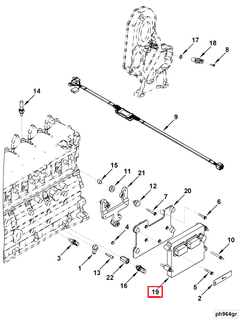

Proper installation and integration of the Cummins 4359433 ECM are crucial for its effective operation. This process involves connecting the ECM to the truck’s sensor network and configuring it to work with the existing systems. Careful attention to wiring and software settings ensures that the ECM can communicate efficiently with other components, maximizing its benefits 4.

Troubleshooting Common Issues

Identifying and resolving common issues with the Cummins 4359433 ECM involves a systematic approach. Common problems may include error codes indicating sensor malfunctions or performance issues. Diagnostic tools can help pinpoint these issues, allowing for targeted repairs or adjustments. Regular monitoring and maintenance can prevent many of these problems, ensuring the ECM operates smoothly 2.

Maintenance and Care

Regular maintenance and care of the Cummins 4359433 ECM are essential for its longevity and performance. This includes routine checks for software updates, ensuring all connections are secure, and performing diagnostic tests to identify potential issues early. Proper maintenance not only extends the life of the ECM but also ensures consistent performance and reliability of the truck 3.

Upgrading and Compatibility

The Cummins 4359433 ECM offers opportunities for upgrades that can enhance its functionality and compatibility with other systems. These upgrades may include software updates that improve performance or add new features. Ensuring compatibility with other truck components is vital for seamless integration and optimal operation 4.

Compatibility of Cummins Electronic Control Module Part 4359433

The Cummins Electronic Control Module (ECM) part number 4359433 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This ECM is compatible with the following engines:

- ISB5.9 G CM2180

- ISB6.7 G CM2180 B118

- ISL G CM2180

- ISX12 G CM2180 EJ

These engines, while differing in displacement and specific applications, share a commonality in their requirement for precise electronic control to manage performance, fuel efficiency, and emissions. The ECM part 4359433 is engineered to interface with these engines, providing the necessary electronic signals and control mechanisms to ensure they operate at peak efficiency.

For the ISB5.9 G CM2180 and ISB6.7 G CM2180 B118, the ECM plays a crucial role in managing the engine’s power output and fuel injection timing, which are critical for maintaining performance in various applications, from on-highway to off-highway use.

In the ISL G CM2180, the ECM is integral to controlling the engine’s response to varying load conditions, ensuring smooth and efficient operation, particularly in heavy-duty applications.

The ISX12 G CM2180 EJ benefits from the ECM’s advanced capabilities, which include managing the engine’s complex systems to deliver high power output while adhering to stringent emissions standards.

By ensuring compatibility with these engines, the Cummins ECM part 4359433 provides a reliable and efficient solution for maintaining engine performance and longevity.

Role of Part 4359433 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM), part 4359433, is integral to the operation of modern engine systems. It acts as the central processing unit, interpreting data from various sensors and executing commands to optimize engine performance.

Interaction with Engine Control Module (ECM)

The ECM, part 4359433, works in tandem with the Engine Control Module to manage fuel injection, ignition timing, and emissions control. It processes real-time data from oxygen sensors, throttle position sensors, and engine temperature sensors to adjust engine parameters dynamically.

Coordination with Electronic Service Calibration

Part 4359433 ECM is also essential for Electronic Service Calibration. It ensures that the engine operates within manufacturer specifications after maintenance or component replacement. The ECM adjusts fuel maps, ignition advance curves, and other critical parameters to maintain optimal performance and efficiency.

Sensor Data Integration

The ECM integrates data from numerous sensors, including Mass Air Flow (MAF) sensors, Manifold Absolute Pressure (MAP) sensors, and Camshaft Position (CMP) sensors. This data allows the ECM to make precise adjustments to fuel delivery and ignition timing, enhancing engine responsiveness and fuel economy.

Feedback Loops

Part 4359433 ECM establishes feedback loops with various engine components. For instance, it receives data from the oxygen sensors to fine-tune the air-fuel mixture. Similarly, it uses input from the Knock Sensor (KS) to adjust ignition timing, preventing engine knock and ensuring smooth operation.

Emission Control Systems

The ECM plays a significant role in emission control systems. It monitors data from the Exhaust Gas Recirculation (EGR) system and the Catalytic Converter to ensure compliance with emission standards. The ECM adjusts EGR valve operation and fuel injection timing to minimize harmful emissions.

Adaptive Learning

One of the advanced features of part 4359433 ECM is its adaptive learning capability. Over time, it learns the unique characteristics of the engine and driving conditions, making subtle adjustments to improve performance and efficiency. This adaptive learning helps in maintaining optimal engine operation under varying conditions.

Communication with Other Modules

The ECM communicates with other vehicle modules, such as the Transmission Control Module (TCM) and the Anti-lock Braking System (ABS), to ensure harmonious operation of all vehicle systems. This inter-module communication enhances overall vehicle performance and safety.

Conclusion

In summary, part 4359433 Electronic Control Module is a sophisticated component that ensures the engine operates efficiently, reliably, and within specified parameters, making it a cornerstone of modern engine management systems.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ -

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ ↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.