3330601

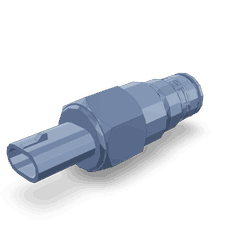

Electronic Fuel Control Actuator

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3330601 Electronic Fuel Control Actuator is designed to enhance the operation of heavy-duty trucks by regulating fuel delivery within the engine, ensuring optimal performance and efficiency. This actuator maintains the balance between power output, fuel consumption, and emissions, contributing to the overall effectiveness of the truck’s engine system 1.

Basic Concepts of Electronic Fuel Control Actuators

An Electronic Fuel Control Actuator modulates the amount of fuel injected into an engine’s combustion chamber. It operates within a fuel injection system, receiving signals from the engine management system to adjust fuel delivery based on various operating conditions. This role is vital for optimizing fuel efficiency, enhancing engine performance, and controlling emissions 2.

Purpose and Role in Truck Operation

The Cummins 3330601 Electronic Fuel Control Actuator precisely controls the fuel injection process in heavy-duty truck engines. It ensures that the correct amount of fuel is delivered at the right time, which is essential for maintaining power output and efficiency. Additionally, it facilitates cleaner combustion, thereby reducing the truck’s environmental impact 3.

Key Features

The Cummins 3330601 Electronic Fuel Control Actuator is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. Technological advancements incorporated into its design enhance its performance, allowing for precise fuel delivery and improved engine responsiveness. These features contribute to the actuator’s effectiveness in demanding heavy-duty applications.

Benefits

Utilizing the Cummins 3330601 Electronic Fuel Control Actuator offers several advantages. It contributes to improved fuel economy by optimizing fuel delivery, leading to cost savings over time. Enhanced engine performance is another benefit, as the actuator ensures that the engine operates efficiently under various conditions. Additionally, it aids in reducing emissions, aligning with environmental regulations and promoting sustainable operation. The actuator’s durability ensures long-term reliability, minimizing the need for frequent replacements.

Integration with Engine Management Systems

The Cummins 3330601 Electronic Fuel Control Actuator integrates seamlessly with the engine management system, providing precise control over fuel injection timing and quantity. This integration allows for dynamic adjustments to fuel delivery based on real-time data from the engine, optimizing performance and efficiency. The actuator’s ability to communicate with the engine management system ensures that fuel injection is finely tuned to meet the engine’s needs.

Common Issues and Troubleshooting

Common issues with the Cummins 3330601 Electronic Fuel Control Actuator may include malfunctions due to electrical faults, wear and tear, or contamination. Troubleshooting these issues involves checking electrical connections, inspecting the actuator for physical damage, and ensuring that the fuel system is clean and free of debris. Diagnostic procedures may include testing the actuator’s response to commands from the engine management system and checking for error codes that indicate specific problems.

Maintenance Recommendations

To ensure optimal performance and longevity of the Cummins 3330601 Electronic Fuel Control Actuator, regular maintenance is recommended. This includes inspecting the actuator for signs of wear or damage, cleaning it to remove any contaminants, and following manufacturer guidelines for replacement intervals. Proper maintenance helps prevent issues and ensures that the actuator continues to operate efficiently.

Cummins Corporation

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation and quality. With a history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the manufacturing of automotive components.

Compatibility

The Cummins Electronic Fuel Control Actuator part number 3330601 is designed to work seamlessly with a range of Cummins engines, ensuring precise control over fuel delivery and engine performance.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series line, which is known for its reliability and efficiency in various applications. The 3330601 actuator is compatible with these engines, providing the necessary electronic control to optimize fuel efficiency and power output.

QSK Engines

The QSK19 CM500, QSK45 CM500, and QSK60 CM500 engines are part of Cummins’ QSK Series, which is designed for heavy-duty applications. These engines benefit from the precise control offered by the 3330601 actuator, ensuring that the engine operates at peak performance under various load conditions.

NH/NT Engines

The NH/NT 855 engines are part of Cummins’ agricultural and construction equipment lineup. The 3330601 actuator is engineered to work with these engines, providing the necessary electronic control to manage fuel delivery effectively, ensuring optimal performance and efficiency in demanding environments.

Each of these engines relies on the 3330601 actuator to maintain precise control over fuel delivery, ensuring that the engine operates efficiently and reliably. This compatibility across different engine series highlights the versatility and importance of the 3330601 actuator in Cummins’ engine lineup.

Role in Engine Systems

The 3330601 Electronic Fuel Control Actuator is integral to the efficient operation of modern engine systems. It works in conjunction with several key components to ensure optimal fuel delivery and engine performance.

Integration with Engine Control Module (ECM)

The Electronic Fuel Control Actuator communicates directly with the Engine Control Module (ECM). The ECM processes data from various sensors and sends signals to the actuator to adjust fuel delivery based on driving conditions, ensuring the engine operates within specified parameters.

Coordination with Electronic Control Pressure Valve

This actuator plays a significant role in managing the Electronic Control Pressure Valve. By modulating the pressure within the fuel system, it helps maintain consistent fuel pressure, which is essential for stable engine operation and fuel efficiency.

Interaction with Fuel Pump and Fuel Shutoff Valve

The actuator works in tandem with the fuel pump to regulate the amount of fuel entering the system. It also interacts with the fuel shutoff valve to ensure that fuel flow is precisely controlled, preventing issues such as fuel starvation or over-fueling.

Fuel Injection System Optimization

In fuel injection systems, the Electronic Fuel Control Actuator fine-tunes the injection timing and quantity. This precise control enhances combustion efficiency, reduces emissions, and improves overall engine performance.

Plumbing and Fuel Lines

The actuator is connected to the fuel lines and plumbing within the engine system. It ensures that the fuel flow is consistent and meets the demands of the engine under varying conditions, from idle to full throttle.

Module and Code Interpretation

The actuator relies on data from various modules and diagnostic codes to make real-time adjustments. This data-driven approach allows for dynamic fuel management, adapting to changes in engine load, temperature, and other operating conditions.

Spare Parts Kit Compatibility

When included in a spare parts kit, the Electronic Fuel Control Actuator is designed to be a drop-in replacement, ensuring that maintenance or repairs can be performed with minimal downtime and maximum efficiency.

Conclusion

The Cummins 3330601 Electronic Fuel Control Actuator is a sophisticated component that enhances the functionality and performance of engine systems by precisely controlling fuel delivery in coordination with other critical components. Its integration with the engine management system, coordination with the Electronic Control Pressure Valve, and interaction with the fuel pump and fuel shutoff valve ensure optimal fuel delivery and engine performance. Regular maintenance and troubleshooting are essential to ensure the longevity and efficiency of this actuator.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.