2888011

Engine Connecting Rod

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

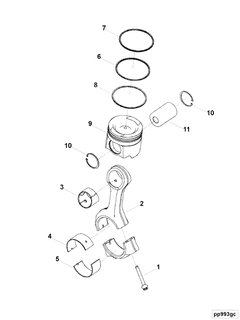

The Cummins 2888011 Engine Connecting Rod is a critical component in the engine systems of heavy-duty trucks. It facilitates the transfer of motion from the piston to the crankshaft, playing a significant role in the engine’s operation. This part is engineered to withstand the rigorous demands of heavy-duty applications, ensuring reliable performance and efficiency.

Basic Concepts of Engine Connecting Rods

An engine connecting rod serves as a link between the piston and the crankshaft within an internal combustion engine. Its primary function is to convert the linear motion of the piston into rotational motion of the crankshaft. This conversion is fundamental to the engine’s operation, enabling it to produce power. The connecting rod operates under significant stress and must be designed to endure high loads and dynamic forces 1.

Purpose of the Cummins 2888011 Engine Connecting Rod

The Cummins 2888011 Engine Connecting Rod is designed to transfer motion from the piston to the crankshaft in truck engines. This transfer is achieved through the rod’s connection at one end to the piston via the piston pin and at the other end to the crankshaft via the crankshaft journal. The efficient and smooth operation of this component is vital for the overall performance and reliability of the engine.

Key Features

The Cummins 2888011 Engine Connecting Rod features several key attributes that enhance its performance and durability. These include a robust material composition, typically involving high-strength alloys, which provide the necessary resilience against the stresses encountered in heavy-duty applications. The design elements of the rod, such as its precise machining and balanced weight distribution, contribute to its efficient operation. Additionally, any unique characteristics, such as specialized coatings or treatments, further enhance its performance under demanding conditions.

Benefits

The Cummins 2888011 Engine Connecting Rod offers several benefits that contribute to improved engine efficiency, enhanced durability, and reliable performance under heavy-duty conditions. Its high-strength material composition and precise engineering allow it to withstand the rigors of heavy-duty truck operation, ensuring long-lasting performance. The efficient transfer of motion from the piston to the crankshaft enhances engine efficiency, while the rod’s durability contributes to the overall reliability of the engine.

Installation Considerations

Proper installation of the Cummins 2888011 Engine Connecting Rod is crucial for ensuring optimal performance. Installation procedures should include adhering to specified torque values for securing the rod to the piston and crankshaft, performing alignment checks to ensure proper orientation, and following any special considerations outlined by the manufacturer. Attention to these details during installation helps to prevent issues and ensures the rod operates as intended.

Troubleshooting and Maintenance

Common issues related to engine connecting rods, such as rod knock or bearing failure, can often be traced back to installation errors, material fatigue, or insufficient lubrication. Regular maintenance practices, including monitoring oil levels and quality, inspecting for signs of wear or damage, and following recommended service intervals, can help prolong the lifespan of the connecting rod. Addressing issues promptly and performing maintenance as prescribed can prevent more serious problems and ensure continued reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality automotive components that meet the demanding requirements of heavy-duty applications. The company’s dedication to excellence and customer satisfaction is evident in its wide range of products, including the Cummins 2888011 Engine Connecting Rod.

Compatibility with Cummins Engines

The Cummins Engine Connecting Rod part number 2888011 is designed to fit seamlessly with several Cummins engine models. This part is integral to the engine’s operation, connecting the piston to the crankshaft and facilitating the conversion of linear motion into rotational motion.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The 2888011 connecting rod is compatible with the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The connecting rod ensures smooth operation and durability, contributing to the overall efficiency of these engines.

QSX11.9 CM2250 ECF

Similarly, the 2888011 connecting rod is also suitable for the QSX11.9 CM2250 ECF engine. This engine variant is designed for applications requiring high power and efficiency, and the connecting rod plays a crucial role in maintaining the engine’s performance under demanding conditions.

Grouping of Compatible Engines

The ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines can be grouped together due to their similar design and performance characteristics. Both engines benefit from the 2888011 connecting rod, which is engineered to handle the specific demands of these models.

The QSX11.9 CM2250 ECF engine, while distinct in its application and design, also relies on the 2888011 connecting rod for optimal performance. This part ensures that the engine operates smoothly and efficiently, meeting the high standards expected in its intended use.

Role of Part 2888011 Engine Connecting Rod in Engine Systems

The part 2888011 Engine Connecting Rod is integral to the efficient operation of various engine components. It serves as the vital link between the piston and the crankshaft, facilitating the conversion of linear motion into rotational motion. This conversion is essential for the engine’s power delivery.

Interaction with the Camshaft

The camshaft operates in conjunction with the connecting rod to enhance engine performance. As the camshaft opens and closes the valves at precise intervals, the connecting rod ensures that the piston’s motion is effectively transferred to the crankshaft. This synergy allows for optimal air-fuel mixture intake and exhaust, contributing to smoother engine operation and increased efficiency.

Contribution to Performance Parts

In high-performance engines, the connecting rod’s role becomes even more pronounced. When paired with performance parts, such as upgraded pistons and crankshafts, the connecting rod must withstand higher stresses and deliver more power. Its design and material properties are tailored to handle these demands, ensuring that the engine can operate at elevated performance levels without compromising durability.

Integration with Piston Cooling Nozzle

The connecting rod also plays a part in the engine’s cooling system, particularly when integrated with a piston cooling nozzle. As the piston moves within the cylinder, it generates significant heat. The piston cooling nozzle sprays oil onto the underside of the piston to dissipate this heat. The connecting rod, by maintaining the piston’s position and motion, ensures that the cooling process is consistent and effective, preventing overheating and potential engine damage.

Overall Engine Harmony

In summary, the part 2888011 Engine Connecting Rod is a cornerstone component that ensures the harmonious operation of various engine parts. Its interaction with the camshaft, contribution to performance enhancements, and integration with cooling systems underscore its importance in maintaining engine efficiency and reliability.

Conclusion

The Cummins 2888011 Engine Connecting Rod is a vital component in heavy-duty truck engines, ensuring the efficient transfer of motion from the piston to the crankshaft. Its robust design, high-strength material composition, and precise engineering contribute to the overall performance and reliability of the engine. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the lifespan and efficiency of this critical part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.