This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

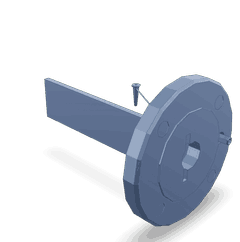

The Cummins 2892193 Engine Alignment Fixture is a specialized tool designed for the precise alignment of engine components during the installation or repair of heavy-duty truck engines. This Cummins part plays a significant role in ensuring that engine parts are correctly positioned, which is vital for maintaining optimal engine performance and longevity. Its application is particularly important in the context of heavy-duty trucks, where engine efficiency and reliability are paramount 1.

Purpose and Functionality

The Cummins 2892193 Engine Alignment Fixture serves to ensure the accurate alignment of engine components. Proper alignment is fundamental to the efficient operation of an engine, as it allows for the smooth interaction of moving parts, reduces friction, and minimizes wear and tear 2. By facilitating precise alignment, this fixture contributes to enhanced engine performance and extends the lifespan of engine components.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials, which ensure durability and reliability. Its design incorporates features that allow for easy adjustment and secure positioning of engine parts. Additionally, the fixture may include unique attributes such as ergonomic handles for ease of use and compatibility with a wide range of engine models, enhancing its effectiveness in various repair and maintenance scenarios.

Benefits of Using the Cummins 2892193 Engine Alignment Fixture

Utilizing the Cummins 2892193 Engine Alignment Fixture offers several advantages. It improves engine efficiency by ensuring that components are aligned correctly, which can lead to better fuel economy and reduced emissions. Furthermore, it helps in reducing wear and tear on engine parts, thereby lowering the risk of premature failure. Accurate alignment also facilitates the precise reassembly of the engine, which is crucial for maintaining performance standards 3.

Installation and Usage Guidelines

To install and use the Cummins 2892193 Engine Alignment Fixture, follow these steps: First, ensure the engine is securely mounted and all necessary safety precautions are in place. Next, position the fixture according to the manufacturer’s instructions, making adjustments as needed for the specific engine model. Use the fixture to align engine components during installation or repair, ensuring each part is correctly positioned. Always refer to the provided guidelines for best practices and safety precautions to achieve optimal results.

Troubleshooting Common Issues

When using the Engine Alignment Fixture, potential issues may include difficulty in aligning components or the fixture not fitting securely. To address these, verify that the fixture is correctly positioned and adjusted for the specific engine model. If alignment issues persist, recheck the engine’s mounting and ensure all components are free from obstructions. Regular maintenance and inspection of the fixture can help prevent such issues.

Maintenance and Care

To prolong the lifespan and ensure consistent performance of the Cummins 2892193 Engine Alignment Fixture, routine maintenance is recommended. This includes cleaning the fixture after each use to remove any debris or contaminants, inspecting it for signs of wear or damage, and storing it in a dry, secure location. Following these maintenance procedures will help maintain the fixture’s effectiveness and reliability over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry for producing reliable and efficient engine components and accessories. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks.

Understanding the Role of Part 2892193 Engine Alignment Fixture in Engine Systems

When integrating part 2892193, the Engine Alignment Fixture, into engine systems, it serves as a fundamental tool for ensuring precise alignment during assembly or maintenance procedures. This fixture is instrumental in aligning various engine components to exacting standards, which is essential for optimal engine performance and longevity.

Key Components and Their Alignment

-

Crankshaft and Connecting Rods: The Engine Alignment Fixture assists in positioning the crankshaft and connecting rods with precision. Proper alignment here ensures smooth operation and reduces wear on these critical components.

-

Cylinder Block: During engine assembly, the fixture helps in aligning the cylinder block with other engine parts. This alignment is vital for maintaining the integrity of the combustion chambers and ensuring uniform cylinder pressure.

-

Camshaft and Valve Train: Aligning the camshaft with the valve train components is another area where the Engine Alignment Fixture proves invaluable. Accurate alignment here ensures proper valve timing, which is essential for efficient combustion and overall engine performance.

-

Pistons and Cylinders: The fixture aids in the precise placement of pistons within the cylinders. This alignment is crucial for maintaining the correct clearances and ensuring that the pistons move smoothly without excessive friction.

-

Flywheel and Clutch Assembly: For engines with manual transmissions, the Engine Alignment Fixture helps in aligning the flywheel with the clutch assembly. This ensures a smooth engagement and disengagement of the clutch, contributing to a more reliable driving experience.

-

Timing Belt or Chain: Proper alignment of the timing belt or chain is essential for synchronized operation of the engine’s moving parts. The fixture ensures that these components are correctly positioned, preventing potential engine damage due to misalignment.

-

Intake and Exhaust Manifolds: The Engine Alignment Fixture also plays a role in aligning the intake and exhaust manifolds with the cylinder head. This alignment is important for efficient airflow into and out of the engine, directly impacting performance and emissions.

-

Sensors and Actuators: Modern engines are equipped with various sensors and actuators that require precise placement. The fixture ensures that these components are aligned correctly, allowing for accurate data collection and efficient engine management.

By utilizing part 2892193 Engine Alignment Fixture, engineers and mechanics can achieve a high degree of accuracy in engine component alignment, leading to improved engine performance, reduced maintenance needs, and extended engine life.

Conclusion

The Cummins 2892193 Engine Alignment Fixture is an indispensable tool in the maintenance and repair of heavy-duty truck engines. Its role in ensuring precise alignment of engine components contributes significantly to engine efficiency, reliability, and longevity. Proper use and maintenance of this fixture are essential for achieving optimal engine performance and minimizing the risk of component failure.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.