This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Engine Brake Adjusting Screw, identified by Cummins part number 2899564, is a critical component in the engine braking system of heavy-duty trucks. Manufactured by Cummins, a leader in diesel engine technology, this part is designed to enhance the functionality and safety of the engine braking system. Its role is to modulate the engine braking force, contributing to the overall control and performance of the vehicle, especially during descents.

Function and Operation

The Engine Brake Adjusting Screw operates by fine-tuning the engine braking system. It is part of a mechanism that adjusts the valve timing to control the amount of air that enters the engine cylinders during the compression stroke. By modulating this air intake, the screw directly influences the engine’s braking force. This adjustment allows for a more controlled deceleration, which is particularly beneficial when navigating downhill slopes or in situations requiring rapid speed reduction.

Purpose of the Engine Brake Adjusting Screw

In the operation of a heavy-duty truck, the Engine Brake Adjusting Screw plays a role by allowing the driver to modulate the engine braking force. This modulation is crucial for maintaining safe and efficient vehicle control, especially during descents. By providing a means to adjust the braking force, the screw helps in managing the truck’s speed and reducing the reliance on the service brakes, thereby extending their lifespan and enhancing overall driving safety 1.

Key Features

The Engine Brake Adjusting Screw is characterized by its robust design and construction, which are tailored to withstand the demanding conditions of heavy-duty trucking. It is made from high-quality materials that ensure durability and reliability. The screw’s design allows for precise adjustments, which is vital for the fine-tuning of engine braking performance. Additionally, its compatibility with various Cummins engine models underscores its versatility and widespread applicability in the heavy-duty trucking sector.

Benefits

Utilizing the Engine Brake Adjusting Screw in heavy-duty trucks offers several advantages. It contributes to improved driving safety by providing a means to control engine braking force, which is particularly useful in challenging driving conditions. Enhanced engine braking performance leads to more efficient vehicle control, reducing the strain on the service brakes and potentially leading to fuel efficiency gains. The screw’s adjustability also allows for customization of the braking force to suit different driving scenarios and preferences 2.

Installation and Adjustment

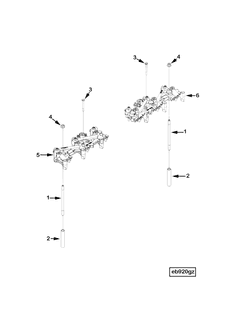

Proper installation and adjustment of the Engine Brake Adjusting Screw are vital for ensuring optimal performance and longevity. The installation process involves securing the screw in its designated position within the engine braking system. Adjustments should be made according to the manufacturer’s guidelines to achieve the desired engine braking force. Regular checks and adjustments may be necessary to maintain the screw’s effectiveness, especially after significant use or in response to changing driving conditions.

Troubleshooting Common Issues

Common issues associated with the Engine Brake Adjusting Screw may include improper adjustment, leading to either insufficient or excessive engine braking force. Troubleshooting steps involve checking the screw’s position and making necessary adjustments to correct the braking force. Regular inspections can help identify wear or damage to the screw, allowing for timely replacement or repair to maintain efficient engine braking.

Maintenance Tips

To ensure the Engine Brake Adjusting Screw remains in optimal condition, regular maintenance practices are recommended. This includes periodic inspections to check for wear, damage, or misalignment. Cleaning the screw and its surrounding components can prevent buildup that might affect its operation. Following the manufacturer’s guidelines for adjustment and maintenance intervals will help maintain the screw’s performance and durability.

Compatibility and Applications

The Engine Brake Adjusting Screw is compatible with a range of Cummins engine models, making it suitable for various heavy-duty trucking applications. Its applications span across different trucking scenarios, from long-haul transportation to specialized heavy-duty operations, demonstrating its versatility and importance in the industry.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry. The company’s commitment to advancing diesel engine technology is evident in its wide range of products, including the Engine Brake Adjusting Screw, which exemplifies Cummins’ dedication to enhancing engine performance and reliability.

Engine Brake Adjusting Screw Compatibility

The Engine Brake Adjusting Screw, part number 2899564, manufactured by Cummins, is a critical component for the proper functioning of the engine brake system. This screw is designed to fine-tune the engine brake’s performance, ensuring optimal responsiveness and efficiency across various engine models.

ISX12 Series

The ISX12 series engines, including the ISX12 CM2350 X102 and ISX12 G CM2180 EJ, benefit from the precise adjustments provided by the 2899564 screw. This part ensures that the engine brake operates smoothly, providing the necessary resistance to control engine speed during deceleration.

ISX12/ISX11.9 Series

The ISX12/ISX11.9 CM2250 engine also integrates the 2899564 screw seamlessly. This engine model, known for its robust performance, relies on the adjusting screw to maintain the engine brake’s effectiveness, enhancing both fuel efficiency and driver control.

QSX11.9 Series

For the QSX11.9 CM2250 ECF engine, the 2899564 screw is equally essential. This engine, designed for heavy-duty applications, requires precise calibration of the engine brake to handle the demands of its operational environment. The adjusting screw ensures that the engine brake delivers consistent performance, contributing to the engine’s overall reliability and longevity.

Each of these engines, despite their differences, shares a common need for the 2899564 Engine Brake Adjusting Screw to maintain optimal engine brake functionality. This part’s compatibility across these models underscores its importance in ensuring that the engine brake system operates as intended, providing essential benefits such as improved fuel economy, enhanced driver control, and reduced wear on the braking system.

Role of Part 2899564 Engine Brake Adjusting Screw in Engine Systems

The Engine Brake Adjusting Screw, identified as part 2899564, is integral to the functionality and maintenance of various engine systems. Its primary role is to fine-tune the performance of the engine brake, ensuring optimal operation and efficiency.

Integration with the Brake System

In the brake system, the Engine Brake Adjusting Screw allows for precise adjustments to the brake’s engagement point. This ensures that the brake responds accurately to driver inputs, enhancing both safety and performance. Proper adjustment is essential for maintaining consistent braking power and preventing premature wear on brake components.

Contribution to Engine Performance

Within the engine system, this screw plays a significant role in the engine brake mechanism. It helps in calibrating the engine brake to work in harmony with the engine’s overall performance. By allowing for minor adjustments, it ensures that the engine brake does not overly strain the engine, thus promoting longevity and reliability.

Importance in Engine Brake Repair Kits

When it comes to engine brake repair kits, the Engine Brake Adjusting Screw is often a key component. It facilitates the recalibration of the engine brake after repairs or replacements, ensuring that the brake system returns to its optimal state. This screw enables technicians to make necessary adjustments post-repair, guaranteeing that the engine brake functions as intended.

Enhancing Engine Brake Efficiency

The Engine Brake Adjusting Screw contributes to the efficiency of the engine brake by allowing for adjustments that can reduce unnecessary strain on the engine. This not only improves the overall performance of the engine but also contributes to fuel efficiency. By ensuring that the engine brake is properly calibrated, this screw helps in maintaining a balance between braking power and engine health.

Conclusion

The Engine Brake Adjusting Screw (part 2899564) is a vital component in the maintenance and optimization of engine brake systems. Its role in fine-tuning the brake’s performance, contributing to engine efficiency, and facilitating repairs makes it an essential part of any engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.