This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

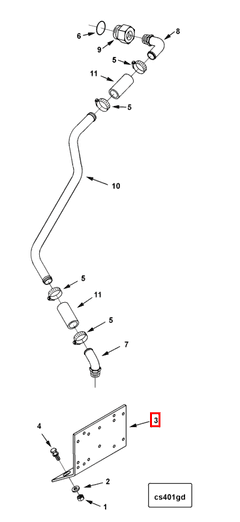

The Cummins 3000268 Engine Heater Bracket is a vital component designed to support the engine heating system in commercial trucks. It facilitates the mounting and secure positioning of the engine heater, contributing to the overall efficiency and reliability of the engine, particularly in challenging environmental conditions 1.

Purpose and Functionality

The primary role of the Engine Heater Bracket is to provide a stable and secure platform for the engine heater. This ensures that the heater is correctly positioned to deliver warm air into the engine compartment. By maintaining optimal engine temperature, it aids in achieving quicker engine start-ups, especially in cold weather conditions. This functionality is essential for preserving engine components from the stress of cold starts and for ensuring that the engine operates within its designed parameters from the moment it is started 2.

Key Features

This Cummins part is engineered with several key features that enhance its performance and durability. It is constructed from high-strength materials to withstand the rigors of commercial truck operations. The design incorporates precise mounting points to ensure a secure fit and alignment with the engine heater. Additionally, the bracket is designed to be corrosion-resistant, which is crucial for longevity in various operating environments 3.

Benefits

The installation of the Engine Heater Bracket offers several benefits. It significantly improves engine start-up performance in cold weather, reducing the strain on the engine during start-up. This can lead to reduced wear and tear on engine components over time. Furthermore, by ensuring the engine reaches its optimal operating temperature more quickly, the bracket contributes to enhanced overall engine efficiency and performance 4.

Installation and Compatibility

Proper installation of the Engine Heater Bracket is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is securely fastened and correctly aligned with the engine heater. Compatibility with various Cummins engine models is an important consideration, and specific installation requirements may vary depending on the engine model. It is recommended to consult the manufacturer’s documentation for detailed compatibility and installation instructions.

Maintenance and Troubleshooting

Regular maintenance of the Engine Heater Bracket is important to ensure its longevity and optimal performance. This includes checking for any signs of wear or damage, ensuring all mounting points are secure, and verifying that the bracket is free from corrosion. Common issues may include loose mounting points or corrosion, which can be addressed by tightening fasteners or applying a corrosion-resistant coating as needed.

Safety Considerations

When installing or maintaining the Engine Heater Bracket, it is important to observe safety precautions. This includes ensuring the engine is off and cool before beginning any work. Mechanics should use appropriate personal protective equipment (PPE) and follow all safety guidelines provided by the manufacturer to prevent injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company is committed to delivering reliable and efficient engine components that meet the demanding requirements of commercial applications.

Compatibility with Cummins Engines

The Engine Heater Bracket part number 3000268 is designed to fit a variety of Cummins engines, ensuring a secure and reliable mounting for the engine heater. This bracket is essential for maintaining the integrity and functionality of the engine heater system, which is crucial for cold-weather operations.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series line, known for their robust design and reliability. The 3000268 bracket is engineered to fit these engines seamlessly, providing a stable platform for the engine heater.

N-Series Engines

The N14 MECHANICAL engine, a staple in the N-Series lineup, also benefits from the 3000268 heater bracket. This bracket is specifically designed to align with the unique mounting points of the N14, ensuring a secure fit and optimal heater performance.

QSK Engines

The QSK19 CM500 engine, part of Cummins’ QSK series, is another engine that is compatible with the 3000268 heater bracket. This bracket is tailored to fit the specific design of the QSK19, providing a reliable mounting solution for the engine heater.

NH/NT Engines

The NH/NT 855 engine, a member of the NH/NT series, is also compatible with the 3000268 heater bracket. This bracket is designed to fit the unique mounting requirements of the NH/NT 855, ensuring that the engine heater is securely and effectively mounted.

V-Series Engines

The V28 engine, part of Cummins’ V-Series, is another engine that can utilize the 3000268 heater bracket. This bracket is engineered to fit the V28’s specific design, providing a reliable and secure mounting solution for the engine heater.

By ensuring compatibility with these various engines, the 3000268 heater bracket from Cummins provides a versatile and reliable solution for maintaining engine heater functionality across a wide range of engine types.

Role of Part 3000268 Engine Heater Bracket in Engine Systems

The Engine Heater Bracket is an essential component in the assembly and operation of various engine starting aids and accessories. This bracket serves as a mounting point for several critical components that enhance engine performance, particularly in cold start conditions.

Integration with Coolant Heater Systems

In systems utilizing a coolant heater or coolant heater starting aid, the Engine Heater Bracket provides a secure attachment point for the coolant heater. This ensures that the heater is properly positioned within the engine bay, allowing it to effectively warm the engine coolant before starting. The bracket’s design accommodates different models such as the Kim Hot Start 115V.2500 W and Kim Hot Start 230V.2500 W, ensuring compatibility and stability.

Hydraulic Starting Aid Systems

For engines equipped with a hydraulic starting aid, the Engine Heater Bracket plays a role in mounting the necessary components. It ensures that the hydraulic system is correctly aligned and supported, contributing to the efficient operation of the starting aid. This is particularly important in large engines where precise alignment is necessary for optimal performance.

Cold Start Aid and Safety Controls

The bracket is also integral to the installation of cold start aids and safety controls. By providing a stable mounting solution, it helps in the secure attachment of these components, ensuring they function as intended without risk of detachment or misalignment. This is vital for the reliability and safety of the engine starting process.

Water Heater and Hot Start Systems

In systems that incorporate a water heater or hot start functionality, such as the Kim Hot Start 230V.4000 W or Kim Hot Start 460V.8000 W, the Engine Heater Bracket ensures these components are firmly mounted. This is essential for the consistent delivery of heat to the engine, facilitating easier starts in cold conditions and reducing wear on engine components.

Overall System Compatibility

The Engine Heater Bracket is designed to be versatile, accommodating various heater models and configurations. Whether it’s a coolant heater mtg. or a hotstart bracket mounting, the bracket ensures that all components are securely fastened, contributing to the overall efficiency and reliability of the engine starting system.

This component is a testament to the importance of proper mounting and alignment in enhancing engine performance and ensuring the longevity of starting aids and accessories.

Conclusion

The Cummins 3000268 Engine Heater Bracket plays a crucial role in the efficient and reliable operation of engine heating systems in commercial trucks. Its robust design, compatibility with various Cummins engines, and integration with different starting aids and accessories make it an indispensable component for maintaining optimal engine performance, especially in cold weather conditions. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

-

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.