This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3022883 Engine Lifting Bracket is a specialized component designed to aid in the maintenance and repair of heavy-duty truck engines. This bracket is integral to the process of safely and efficiently removing and installing engines, ensuring that maintenance procedures are conducted with precision and care.

Purpose and Functionality

The Cummins 3022883 Engine Lifting Bracket serves a pivotal role in the operation and maintenance of truck engines. It is engineered to facilitate the engine removal and installation processes by providing a secure point of attachment for lifting equipment. This bracket ensures that the engine can be handled with stability and control, reducing the risk of damage to both the engine and surrounding components during maintenance operations 1.

Key Features

The design of the Cummins 3022883 Engine Lifting Bracket incorporates robust materials and precise engineering to enhance its performance and durability. Constructed from high-strength steel, this bracket is capable of withstanding the significant loads associated with engine lifting. Its design includes features such as reinforced attachment points and a contoured shape that aligns with the engine’s structure, ensuring a secure fit and reliable operation 2.

Benefits

Utilizing the Cummins 3022883 Engine Lifting Bracket offers several advantages. It contributes to improved safety during engine handling by providing a stable and secure attachment point for lifting equipment. This reduces the likelihood of accidents and injuries. Additionally, the bracket enhances the efficiency of maintenance procedures by streamlining the engine removal and installation processes. Over time, this can lead to potential cost savings by minimizing the duration of maintenance downtime and reducing the risk of engine damage 3.

Installation Process

Proper installation of the Cummins 3022883 Engine Lifting Bracket involves several steps to ensure it is securely attached and functions as intended. Begin by identifying the correct mounting locations on the engine, following the manufacturer’s guidelines. Use the appropriate fasteners to attach the bracket, ensuring they are tightened to the specified torque settings. It is important to verify that the bracket is aligned correctly and that all connections are secure before proceeding with engine lifting operations. Adhering to best practices and safety considerations throughout the installation process is crucial to ensure the bracket’s effectiveness and longevity.

Maintenance and Troubleshooting

To maintain the Cummins 3022883 Engine Lifting Bracket and ensure its optimal performance, regular inspections should be conducted to check for signs of wear, corrosion, or damage. Cleaning the bracket and its attachment points can prevent the buildup of debris that may affect its functionality. In the event of common issues such as loose fasteners or misalignment, troubleshooting methods may include retightening fasteners, readjusting the bracket, or, in more severe cases, replacing damaged components. Consistent maintenance and prompt addressing of issues will contribute to the bracket’s longevity and reliability.

Compatibility and Applications

The Cummins 3022883 Engine Lifting Bracket is designed to be compatible with a range of Cummins engines and is suitable for use in various commercial truck settings. Its versatility makes it a valuable tool for fleet managers and maintenance professionals working with heavy-duty trucks.

Safety Considerations

When using the Cummins 3022883 Engine Lifting Bracket, it is important to observe several safety guidelines and precautions. Ensure that all personnel involved in the engine handling process are trained and familiar with the equipment and procedures. Use appropriate personal protective equipment (PPE) and ensure that lifting equipment is rated for the load being handled. Regularly inspect the bracket and lifting equipment for signs of wear or damage before use. By adhering to these safety considerations, both the equipment and the personnel involved can be protected.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to sustainability, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product range extends beyond engines to include filtration, emissions solutions, and power generation systems, demonstrating its comprehensive approach to powering the world.

Cummins Engine Lifting Bracket 3022883 Compatibility

The Cummins Engine Lifting Bracket part number 3022883 is designed to be compatible with a range of Cummins engines, ensuring secure and efficient engine handling during maintenance and installation processes. This bracket is engineered to fit seamlessly with the following Cummins engine models:

- V28 Engines: The 3022883 bracket is specifically tailored to fit V28 engines, providing robust support and ease of use during lifting operations. Its design accommodates the unique structural characteristics of V28 engines, ensuring a secure fit and reliable performance.

The Cummins Engine Lifting Bracket 3022883 is a critical component for mechanics and technicians working with Cummins engines, offering a practical solution for safely lifting and positioning these powerful engines. Its compatibility with V28 engines underscores its versatility and importance in the maintenance and repair of Cummins engine systems.

Role of Part 3022883 Engine Lifting Bracket in Engine Systems

The part 3022883 Engine Lifting Bracket is an essential component in the assembly and maintenance of various engine systems. It facilitates the secure handling and positioning of the engine during installation, removal, or repair processes. Here’s how it integrates with the provided components:

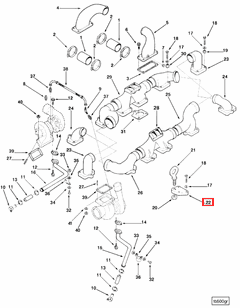

Exhaust System Components

-

Exhaust Manifold: The lifting bracket assists in the precise alignment and secure handling of the exhaust manifold. This ensures that the manifold is correctly positioned relative to the engine block and other exhaust components, maintaining efficient exhaust flow and reducing the risk of leaks.

-

Exhaust Manifold Conversion Kit: When using an exhaust manifold conversion kit, the lifting bracket helps in the safe and stable manipulation of the engine. This is particularly important during the conversion process, where the existing manifold is replaced with a new one, ensuring that all connections are properly aligned.

-

Exhaust Collector Connection Bracket: The lifting bracket aids in the installation and removal of the exhaust collector connection bracket. This component is vital for connecting the exhaust manifold to the exhaust collector, and proper handling ensures a secure and leak-free connection.

-

Exhaust Connection Bracket: Similar to the exhaust collector connection bracket, the lifting bracket is used to manage the exhaust connection bracket. This ensures that the bracket is correctly installed, maintaining the integrity of the exhaust system.

-

Exhaust Outlet Bracket: The lifting bracket is instrumental in handling the exhaust outlet bracket, which connects the exhaust manifold to the exhaust pipe. Proper installation is crucial for efficient exhaust flow and to prevent any potential leaks.

Turbocharger Integration

When a turbocharger is part of the engine system, the lifting bracket plays a significant role in its installation and removal. The turbocharger requires precise alignment with the exhaust manifold and other components. The lifting bracket ensures that the engine is stable and correctly positioned, allowing for accurate turbocharger installation. This is essential for optimal turbocharger performance and longevity.

PDC (Powertrain Control Module) Connection

Although the PDC itself is an electronic component, the lifting bracket indirectly supports its installation by ensuring the engine is securely positioned. This stability is necessary when routing wires and connectors from the PDC to various engine components, including the exhaust system and turbocharger.

General Engine Handling

The lifting bracket is a versatile tool used throughout various engine maintenance procedures. Whether it’s for routine inspections, repairs, or complete engine replacements, the lifting bracket provides the necessary support and stability. This reduces the risk of accidents and ensures that all engine components, including the exhaust system and turbocharger, are handled with care.

Conclusion

In summary, the part 3022883 Engine Lifting Bracket is a fundamental component in the safe and efficient handling of engine systems. Its role in supporting and aligning various exhaust and turbocharger components underscores its importance in maintaining engine performance and integrity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.