This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

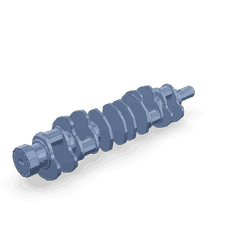

The Cummins 3042800 Engine Crankshaft is a vital component in heavy-duty trucks, playing a significant role in the engine’s operation. This crankshaft is designed to withstand the demanding conditions of heavy-duty applications, ensuring reliable performance and efficiency. Its robust construction and precise engineering contribute to the overall functionality and durability of the engine 1.

Basic Concepts of an Engine Crankshaft

An engine crankshaft is a mechanical part that converts the linear motion of the pistons into rotational motion, which drives the vehicle’s wheels. This conversion is achieved through a series of crankpins and connecting rods attached to the crankshaft. As the pistons move up and down within the cylinders, the connecting rods transfer this motion to the crankshaft, causing it to rotate. This rotational motion is then transmitted through the transmission to the wheels, propelling the vehicle forward 2.

Purpose of the Cummins 3042800 Engine Crankshaft

The Cummins 3042800 Engine Crankshaft serves a pivotal role in the operation of a truck engine. It is responsible for converting the reciprocating motion of the pistons into rotational motion, which is essential for the engine’s function. This crankshaft contributes to engine performance by ensuring smooth and efficient power delivery. Its design enhances the engine’s reliability and efficiency, making it a critical component in heavy-duty truck applications.

Key Features

The Cummins 3042800 Engine Crankshaft boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design includes precision-machined journals and crankpins, which contribute to smooth operation and reduced friction. Additionally, the crankshaft may feature counterweights to balance the rotating assembly, minimizing vibrations and improving overall engine stability.

Benefits

The Cummins 3042800 Engine Crankshaft offers numerous benefits, including improved engine reliability and durability. Its robust construction allows it to withstand the high stresses and loads encountered in heavy-duty applications. Additionally, the precise engineering of the crankshaft can lead to potential increases in power output and fuel efficiency, enhancing the overall performance of the engine.

Installation Process

Installing the Cummins 3042800 Engine Crankshaft requires careful attention to detail. The process involves removing the old crankshaft, inspecting the engine block for any damage, and ensuring that all mating surfaces are clean and free of debris. The new crankshaft is then carefully aligned with the engine’s main bearings and secured in place. Special tools may be required to properly torque the main bearing caps and ensure the crankshaft is installed correctly. It is important to follow the manufacturer’s guidelines to avoid any installation issues.

Common Issues and Troubleshooting

Engine crankshafts can encounter several common issues, such as wear, misalignment, or damage from debris. Symptoms of crankshaft problems may include unusual engine noises, vibrations, or a loss of power. Troubleshooting these issues involves inspecting the crankshaft for signs of wear or damage, checking the alignment of the crankshaft within the engine block, and ensuring that all connecting components are properly secured. In some cases, crankshaft replacement may be necessary to restore engine performance.

Maintenance Tips

Maintaining the Cummins 3042800 Engine Crankshaft is crucial for ensuring optimal performance and longevity. Regular inspections should be conducted to check for signs of wear or damage. Keeping the engine properly lubricated is also important, as this helps reduce friction and wear on the crankshaft. Additionally, following the manufacturer’s recommended maintenance intervals for oil changes and other service procedures can help prevent issues and extend the life of the crankshaft.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is known for producing high-quality engine components, including crankshafts, that are designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and excellence has established it as a leader in the field, providing reliable and efficient engine solutions for a wide range of industries 3.

Cummins Engine Crankshaft 3042800 Compatibility

The Cummins Engine Crankshaft part number 3042800 is a critical component designed to fit seamlessly within various Cummins engine models. This crankshaft is engineered to provide robust performance and reliability, ensuring smooth operation across a range of applications.

V28 Engines

The V28 engine series by Cummins is known for its high power output and durability, making it suitable for heavy-duty applications. The 3042800 crankshaft is specifically tailored to fit these V28 engines, ensuring compatibility and optimal performance. The design of this crankshaft allows it to handle the significant torque and power demands of V28 engines, providing a reliable foundation for the engine’s operation.

Grouping by Application

The 3042800 crankshaft is also compatible with other Cummins engines that share similar design and performance characteristics. This includes engines used in:

- Industrial Applications: Where high power and reliability are paramount.

- Marine Applications: Ensuring smooth and efficient operation in demanding marine environments.

- Construction Equipment: Providing the necessary strength and durability for heavy machinery.

Each of these applications requires a crankshaft that can withstand significant stress and deliver consistent performance, which the 3042800 crankshaft is designed to do.

Role of Part 3042800 Engine Crankshaft in Engine Systems

The part 3042800 Engine Crankshaft is a fundamental component in the orchestration of an engine’s operation, interacting with several other key components to ensure efficient and effective engine performance.

Within the Base Parts of an engine, the crankshaft is pivotal. It converts the linear motion of the pistons into rotational motion, which is then transmitted to the transmission system. This conversion is essential for the vehicle’s propulsion.

The Block, often referred to as the engine block, houses the crankshaft. It provides the structural framework for the engine, supporting the crankshaft and maintaining its alignment with other components.

The Cylinder is another component with which the crankshaft closely interacts. As the pistons move up and down within the cylinders, they drive the crankshaft via the connecting rods. This motion is fundamental to the engine’s operation, as it generates the power needed to move the vehicle.

In a Crankshaft Kit, the crankshaft is often the central piece. This kit may include bearings, seals, and other components necessary for the crankshaft’s installation and function. The crankshaft’s condition and proper installation are vital for the kit’s overall effectiveness.

A Cylinder Block Kit typically includes the cylinder block, pistons, and often the crankshaft. The crankshaft’s role here is to ensure that the newly installed or refurbished components operate in harmony, providing smooth and efficient engine operation.

For engines with a Cylinder Short V-12 Block, the crankshaft is even more significant due to the complex arrangement of the cylinders. The crankshaft must be precisely engineered to handle the power generated by twelve cylinders, ensuring balanced operation and minimizing vibrations.

Conclusion

In summary, the part 3042800 Engine Crankshaft is integral to the function of various engine components. Its interaction with the base parts, block, cylinders, and various kits is essential for the engine’s performance, efficiency, and longevity.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Cummins Inc. Company Overview. Available at: https://www.cummins.com/company/overview (Accessed: 10 October 2023).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.