This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3056082 Engine Brake Slave Piston, manufactured by Cummins, is a critical component in the engine braking systems of heavy-duty trucks. Cummins, a prominent figure in the commercial truck industry, is known for producing high-quality engine components, and this part is no exception. It significantly enhances the performance and safety of heavy-duty vehicles 1.

Basic Concepts of Engine Brake Slave Piston

Engine brake systems are engineered to aid in slowing down or controlling the speed of a vehicle by converting engine power into resistive force. The slave piston is a vital component in these systems, assisting in the modulation of this resistive force. It works in tandem with the master piston and other elements of the engine brake system to ensure effective braking 2.

Function and Operation

This Cummins part operates by receiving hydraulic pressure from the master piston. This pressure causes the slave piston to move, engaging the braking mechanism within the engine. The interaction between the slave piston and other components, such as the valve and the actuator, is essential for the efficient operation of the engine brake system. The precise movement of the slave piston ensures that the engine’s power is effectively converted into braking force 3.

Purpose of the 3056082 Engine Brake Slave Piston

In the operation of a truck, the Engine Brake Slave Piston contributes to engine braking, a method used to slow down the vehicle without relying solely on the traditional braking system. This is particularly beneficial during descents, where prolonged use of regular brakes could lead to overheating and reduced effectiveness. The slave piston aids in maintaining vehicle control and safety by providing an additional means of deceleration 4.

Key Features

The 3056082 is characterized by several design elements that enhance its performance and reliability. These include precision engineering for accurate movement, durable materials to withstand high pressures and temperatures, and a design that ensures smooth operation within the engine brake system. These features contribute to the overall efficiency and longevity of the component.

Benefits

The advantages of this part include improved braking efficiency, allowing for better control of the vehicle, especially during descents. It also helps in reducing wear on the traditional braking systems, extending their lifespan. Additionally, the enhanced vehicle control provided by the engine brake system contributes to safer driving conditions, particularly in challenging terrains or during emergency situations.

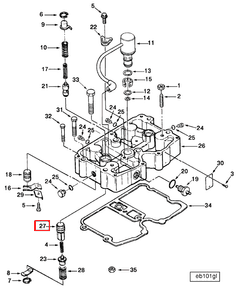

Installation Process

Installing the Engine Brake Slave Piston requires careful attention to detail. The process involves ensuring the engine is cool, using the appropriate tools for removal and installation, and checking the alignment of the piston within the system. It is important to follow the manufacturer’s guidelines to ensure proper installation and functionality.

Troubleshooting Common Issues

Common issues with the Engine Brake Slave Piston may include leaks in the hydraulic system, improper engagement of the braking mechanism, or unusual noises during operation. Diagnostic steps involve checking the hydraulic lines for leaks, ensuring the piston moves freely, and inspecting the engagement of the braking components. Solutions may range from simple adjustments to more complex repairs or replacements.

Maintenance Tips

To ensure the longevity and optimal performance of the Engine Brake Slave Piston, routine maintenance is recommended. This includes regular inspections for wear and tear, checking the hydraulic system for leaks, and ensuring all components are properly aligned and functioning as intended. Adhering to the manufacturer’s maintenance schedule can help prevent issues and extend the life of the component.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. Their product range includes engines, powertrains, and related technologies, all designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The Engine Brake Slave Piston, identified by the part number 3056082 and manufactured by Cummins, is designed to work seamlessly with specific Cummins engine models, ensuring optimal performance and reliability.

N14 CELECT and N14 MECHANICAL Engines

This part is compatible with both the N14 CELECT and N14 MECHANICAL engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The compatibility of the Engine Brake Slave Piston with these engines ensures that the engine brake system functions correctly, providing the necessary resistance to slow down the vehicle without relying solely on the transmission or wheels.

In the N14 CELECT engine, the Engine Brake Slave Piston works in conjunction with the electronic control system to manage the engine brake’s operation. This integration allows for precise control and responsiveness, enhancing the overall driving experience. Similarly, in the N14 MECHANICAL engine, the Engine Brake Slave Piston operates as part of a mechanical system, ensuring that the engine brake provides consistent and reliable performance.

By ensuring that the Engine Brake Slave Piston is correctly installed and functioning, operators of these engines can maintain the integrity of the engine brake system, leading to improved safety and efficiency during operation.

Role in Engine Systems

The Engine Brake Slave Piston (part 3056082) is an integral component within various engine braking systems, particularly those associated with Cummins engines. Its function is to facilitate the operation of the engine brake system by translating hydraulic pressure into mechanical action.

When integrated with a Brake System, the Engine Brake Slave Piston works in conjunction with the brake caliper or drum to apply the necessary force for deceleration. This interaction ensures that the braking force is applied consistently and effectively, enhancing the overall safety and performance of the vehicle.

In the context of an Engine, the slave piston is part of a subsystem that manages the engine’s braking capabilities. It responds to signals from the engine control unit (ECU) to engage the brake, thereby reducing the vehicle’s speed without relying solely on the traditional friction brakes. This not only extends the life of the friction brakes but also provides additional control during descents or in emergency situations.

For systems that include a C Brake Kit or Engine Brake Kit, the Engine Brake Slave Piston is essential for the proper functioning of these kits. It ensures that the engine brake can be engaged and disengaged smoothly, providing drivers with reliable engine braking performance.

Specifically, within Cummins Engine Brake systems, the slave piston is a key component that enhances the effectiveness of the jake brake. It allows for precise control over the braking force, which is particularly beneficial in heavy-duty applications where consistent and powerful braking is required.

Conclusion

The Engine Brake Slave Piston (part 3056082) plays a significant role in various engine braking systems by ensuring that hydraulic pressure is effectively converted into mechanical action, thereby enhancing the performance and safety of the vehicle’s braking system.

-

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.