This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

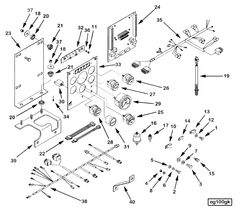

Introduction

The Cummins 3062658 Engine Instrument Panel is a specialized component designed for use in commercial trucks. It serves as a central hub for monitoring and displaying various engine parameters, providing drivers and fleet managers with vital information about the engine’s performance and condition. This instrument panel enhances driver awareness, facilitates proactive maintenance, and contributes to overall vehicle efficiency and safety.

Basic Concepts of Engine Instrument Panels

An engine instrument panel is a control and display unit that provides real-time data about the engine’s operation. It typically includes gauges, lights, and digital displays that convey information such as engine temperature, oil pressure, fuel level, and other critical parameters. The panel functions by receiving data from various sensors located throughout the engine system. These sensors detect changes in engine conditions and transmit this information to the instrument panel, which then processes and displays the data in an easily understandable format for the driver 1.

Purpose of the Cummins 3062658 Engine Instrument Panel

The Cummins 3062658 Engine Instrument Panel plays a role in the operation of a truck by monitoring and displaying critical engine parameters. It provides drivers with immediate feedback on the engine’s performance, allowing them to make informed decisions about vehicle operation. By continuously monitoring engine conditions, the panel helps in identifying potential issues before they become serious problems, thereby contributing to the longevity and reliability of the engine 2.

Key Features

The Cummins 3062658 Engine Instrument Panel is equipped with several key features that enhance its functionality. These include a variety of display types, such as analog gauges and digital readouts, which offer clear and concise information. The panel also integrates with multiple sensors throughout the engine system, ensuring comprehensive monitoring capabilities. Additionally, it features a user-friendly interface that allows drivers to easily navigate through different display options and access critical information at a glance.

Benefits of Using the Cummins 3062658 Engine Instrument Panel

Utilizing the Cummins 3062658 Engine Instrument Panel offers several advantages. It improves engine monitoring by providing real-time data on engine performance, enabling drivers to respond promptly to any anomalies. Enhanced driver awareness is another benefit, as the panel keeps drivers informed about the engine’s condition, promoting safer and more efficient driving practices. Furthermore, the panel contributes to increased safety and efficiency by facilitating early detection of potential issues, reducing the risk of engine failure and improving overall vehicle performance 3.

Installation and Integration

Proper installation and integration of the Cummins 3062658 Engine Instrument Panel within a truck’s engine system are crucial for its effective operation. This process involves connecting the panel to the vehicle’s electrical system and ensuring compatibility with the engine’s sensors and control units. It may also require configuring software settings to optimize the panel’s performance and ensure accurate data display. Following manufacturer guidelines during installation is recommended to avoid potential issues and ensure the panel functions as intended.

Troubleshooting and Maintenance

To maintain optimal performance and longevity of the Cummins 3062658 Engine Instrument Panel, regular troubleshooting and maintenance are necessary. Common issues may include inaccurate readings, display malfunctions, or sensor failures. Troubleshooting typically involves checking electrical connections, verifying sensor functionality, and ensuring software settings are correct. Maintenance tips include keeping the panel clean, protecting it from moisture and extreme temperatures, and performing regular inspections to identify and address any potential problems early on.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation within the commercial truck industry for producing reliable, high-performance engines and components. The company’s commitment to innovation, quality, and customer satisfaction has made it a preferred choice for fleet operators and truck manufacturers worldwide.

Engine Instrument Panel Compatibility with Cummins Part 3062658

The Cummins Engine Instrument Panel, part number 3062658, is designed to integrate seamlessly with a variety of engine models. This panel is a critical component for monitoring and controlling engine performance, providing essential data to the operator and ensuring optimal engine operation.

K19, K38, and K50 Engines

The K19, K38, and K50 engines are part of Cummins’ robust line of medium-duty diesel engines. These engines are known for their reliability and efficiency, making them a popular choice for various applications, including commercial trucks and industrial machinery. The Engine Instrument Panel for these engines is engineered to provide precise readings and controls, ensuring that operators can maintain peak performance and address any issues promptly.

N14 MECHANICAL Engine

The N14 MECHANICAL engine is a high-performance, heavy-duty diesel engine that is widely used in the trucking and construction industries. This engine’s demanding requirements necessitate a highly reliable and accurate instrument panel. The Cummins Engine Instrument Panel for the N14 MECHANICAL engine is designed to handle the high stress and operational demands, providing critical data that helps in maintaining the engine’s efficiency and longevity.

NH/NT 855 Engines

The NH/NT 855 engines are part of Cummins’ line of high-output, heavy-duty diesel engines. These engines are known for their power and durability, making them ideal for heavy-duty applications such as mining and construction. The Engine Instrument Panel for these engines is designed to provide comprehensive monitoring and control, ensuring that operators can maintain optimal performance even under the most challenging conditions.

V28 Engine

The V28 engine is a high-performance, heavy-duty diesel engine that is used in a variety of demanding applications. This engine’s robust design and high output require a highly reliable and accurate instrument panel. The Cummins Engine Instrument Panel for the V28 engine is engineered to provide precise readings and controls, ensuring that operators can maintain peak performance and address any issues promptly.

Each of these engines benefits from the Cummins Engine Instrument Panel, part number 3062658, which is designed to provide essential data and control features that are critical for maintaining engine performance and reliability.

Role of Part 3062658 Engine Instrument Panel in Engine Systems

The part 3062658 Engine Instrument Panel is an integral component in the engine systems, providing essential data and controls that facilitate the operation and monitoring of various engine parameters. This panel interfaces with multiple engine components to ensure optimal performance and safety.

Integration with Engine Components

-

Engine Control Unit (ECU): The Engine Instrument Panel communicates with the ECU to display real-time data such as engine speed (RPM), fuel consumption, and temperature. This information allows for precise control adjustments and ensures the engine operates within safe limits.

-

Sensors: Various sensors, including the Manifold Absolute Pressure (MAP) sensor, Oxygen (O2) sensor, and Coolant Temperature sensor, feed data to the Engine Instrument Panel. This data is crucial for monitoring engine health and performance, enabling timely interventions if anomalies are detected.

-

Fuel Injection System: The panel provides feedback on the fuel injection system’s performance, displaying metrics like fuel pressure and injector performance. This helps in fine-tuning the fuel delivery for efficiency and power output.

-

Ignition System: By monitoring ignition timing and spark plug performance, the Engine Instrument Panel ensures that the ignition system is operating correctly. This is vital for maintaining combustion efficiency and reducing emissions.

-

Exhaust Gas Recirculation (EGR) System: The panel monitors the EGR system’s function, providing data on flow rates and efficiency. This helps in reducing nitrogen oxides (NOx) emissions and improving overall engine performance.

-

Turbocharger (if applicable): In turbocharged engines, the panel displays turbocharger speed and boost pressure. This information is essential for preventing over-boosting and ensuring the turbocharger operates within its designed parameters.

-

Battery and Electrical System: The Engine Instrument Panel also monitors the electrical system, including battery voltage and alternator output. This ensures that the engine’s electrical components receive consistent and adequate power.

-

Transmission (in integrated systems): In engines with integrated transmission systems, the panel provides data on transmission fluid temperature and gear status, aiding in the smooth operation of the vehicle.

By seamlessly integrating with these components, the part 3062658 Engine Instrument Panel plays a significant role in maintaining engine efficiency, performance, and reliability.

Conclusion

The Cummins 3062658 Engine Instrument Panel is a vital component in the operation and maintenance of commercial trucks. By providing real-time data on engine performance and condition, it enhances driver awareness, facilitates proactive maintenance, and contributes to overall vehicle efficiency and safety. Proper installation, regular maintenance, and troubleshooting are essential to ensure the panel functions optimally and provides accurate data. The integration of this part with various engine components underscores its importance in maintaining engine efficiency, performance, and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.