This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

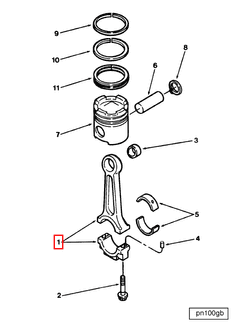

The Cummins 3070449 Engine Connecting Rod is a critical component in the operation of heavy-duty trucks. It serves as a link between the piston and the crankshaft, facilitating the conversion of linear motion into rotational motion. This part’s role is significant in ensuring the efficient and reliable operation of the engine.

Basic Concepts of Engine Connecting Rods

An engine connecting rod, often referred to as a con rod, is a pivotal element in an internal combustion engine. Its primary function is to connect the piston to the crankshaft, transmitting the force generated by the combustion process in the cylinder to the crankshaft. This transmission of force allows the engine to convert the linear motion of the piston into rotational motion, which ultimately drives the vehicle 1.

Purpose of the 3070449 Engine Connecting Rod

The Cummins 3070449 Engine Connecting Rod plays a role in the operation of a truck engine by transmitting force from the piston to the crankshaft. This transmission is crucial for the engine’s operation, as it enables the conversion of the piston’s up-and-down motion into the rotational motion needed to drive the vehicle’s wheels. The efficiency and reliability of this transmission directly impact the engine’s overall performance 2.

Key Features of the 3070449 Engine Connecting Rod

The Cummins 3070449 Engine Connecting Rod is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the high stresses and temperatures within the engine, and its precise design elements that ensure optimal fit and function within the engine assembly. Additionally, any unique characteristics, such as specialized coatings or treatments, contribute to its enhanced performance and longevity 3.

Benefits of Using the 3070449 Engine Connecting Rod

Utilizing the Cummins 3070449 Engine Connecting Rod offers several advantages. These include improved engine efficiency, as the rod’s design and material properties allow for more effective force transmission. Additionally, its reliability and durability contribute to the engine’s longevity, reducing the need for frequent replacements and maintenance. The rod’s performance also plays a role in enhancing the overall efficiency and power output of the engine 4.

Troubleshooting and Maintenance Suggestions

Common issues with engine connecting rods may include wear, fatigue, or damage due to excessive stress or inadequate lubrication. Diagnostic tips for identifying these issues include listening for unusual engine noises, monitoring engine performance, and conducting regular inspections. Maintenance practices to ensure optimal performance and longevity of the 3070449 Engine Connecting Rod include proper lubrication, regular inspections for wear or damage, and timely replacement of worn or damaged components.

Installation and Replacement Procedures

Proper installation and replacement of the Cummins 3070449 Engine Connecting Rod require careful attention to detail and the use of appropriate tools. The process involves removing the old rod, inspecting the engine for any damage or wear, and installing the new rod with precise alignment to ensure optimal function. Precautions include ensuring the engine is cool before beginning work, using the correct torque specifications for tightening components, and following manufacturer guidelines for installation.

Performance Enhancements

The Cummins 3070449 Engine Connecting Rod contributes to overall engine performance by facilitating efficient force transmission from the piston to the crankshaft. This efficiency plays a role in enhancing the engine’s power output and fuel efficiency. The rod’s design and material properties are tailored to withstand the high stresses and temperatures within the engine, ensuring reliable operation under demanding conditions.

Compatibility and Application

The Cummins 3070449 Engine Connecting Rod is designed for specific types of engines and truck models. Its application is tailored to meet the demands of heavy-duty truck engines, ensuring compatibility and optimal performance. Specific application notes may include details on engine size, model compatibility, and any special installation requirements.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s commitment to quality and innovation is evident in its product range, which includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications.

Engine Connecting Rod 3070449 by Cummins

The Engine Connecting Rod 3070449, manufactured by Cummins, is a critical component in various engine configurations. This part plays a pivotal role in the mechanical linkage between the crankshaft and the piston, ensuring efficient power transfer and smooth engine operation.

Compatibility with Cummins Engines

N14 MECHANICAL

The Engine Connecting Rod 3070449 is specifically designed to fit the N14 MECHANICAL engine. This engine is known for its robust construction and reliability, making it a popular choice in heavy-duty applications. The connecting rod’s precision engineering ensures it can withstand the high stresses and torques generated during engine operation, contributing to the overall durability and performance of the N14 MECHANICAL engine.

Other Cummins Engines

While the primary focus here is on the N14 MECHANICAL engine, it is worth noting that Cummins engines often share common components due to their design philosophies and engineering standards. The Engine Connecting Rod 3070449 may also be compatible with other Cummins engines that share similar specifications and requirements. This interchangeability is a testament to Cummins’ commitment to quality and consistency across their engine lineup.

Understanding the Role of Part 3070449 Engine Connecting Rod in Engine Systems

The part 3070449 Engine Connecting Rod is an integral component in the efficient operation of engine systems. It serves as the vital link between the engine piston and the crankshaft, facilitating the conversion of linear motion into rotational motion.

Interaction with Engine Piston

The engine piston moves up and down within the cylinder, driven by the combustion process. The connecting rod is attached to the piston via the piston pin at one end and to the crankshaft at the other. This setup ensures that the force generated by the piston’s movement is effectively transmitted to the crankshaft.

Contribution to Performance

In terms of performance, the connecting rod’s design and material properties are engineered to withstand high stresses and maintain precision under varying engine loads. Its role in transferring power efficiently from the piston to the crankshaft directly influences the engine’s overall performance. High-quality connecting rods, like part 3070449, are often used in performance engines to enhance durability and power output.

Integration with Performance Parts

When integrating part 3070449 with other performance parts, it’s essential to consider the balance and harmony within the engine system. Upgraded pistons, crankshafts, and other components must be compatible to ensure optimal performance and reliability. The connecting rod’s ability to handle increased stress and maintain alignment is key in high-performance applications.

Conclusion

The Cummins 3070449 Engine Connecting Rod plays a significant role in the seamless operation of engine systems by effectively transmitting motion and power, thereby contributing to the engine’s performance and durability. Its design, material properties, and compatibility with various Cummins engines make it a reliable and efficient component for heavy-duty truck applications.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.