3071593

Engine Brake Adjusting Screw

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3071593 Engine Brake Adjusting Screw is a component designed to fine-tune the engine braking system in heavy-duty trucks. Its purpose is to allow for precise modulation of the engine braking force, which is vital for the safe and efficient operation of these vehicles. By adjusting the screw, operators can optimize the performance of the engine brake, ensuring it meets the specific demands of various driving conditions 1.

Function and Operation

The Engine Brake Adjusting Screw operates within the engine braking system by modulating the amount of air that bypasses the turbocharger. This mechanism allows for the adjustment of engine braking force. When the screw is turned, it alters the position of the valve that controls the bypass air, thereby changing the intensity of the engine braking effect. This modulation helps in managing the deceleration of the vehicle, particularly during descents, by converting engine power into braking force 1.

Purpose of the Engine Brake Adjusting Screw

This Cummins part plays a role in enhancing the performance and safety of heavy-duty trucks. By allowing for the fine-tuning of engine braking force, it contributes to controlled deceleration and vehicle stability. This is particularly important in scenarios where traditional braking systems may be insufficient or prone to overheating, such as during prolonged downhill driving. The screw enables drivers to maintain better control over their vehicle’s speed and stability, reducing the risk of accidents 1.

Key Features

The Cummins 3071593 is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability. It features a precise threading mechanism that allows for fine adjustments, and its construction is resistant to the harsh conditions typically encountered in heavy-duty truck operations. Additionally, the screw is designed for easy access and adjustment, facilitating maintenance and ensuring that the engine brake system operates efficiently 1.

Benefits

Utilizing the Cummins 3071593 offers several advantages. It contributes to improved fuel efficiency by optimizing the engine braking system’s performance. This optimization reduces the reliance on traditional braking systems, thereby decreasing wear and tear on brake components. Furthermore, it enhances driver control during descents, providing a safer driving experience by allowing for precise modulation of deceleration forces 1.

Installation and Adjustment

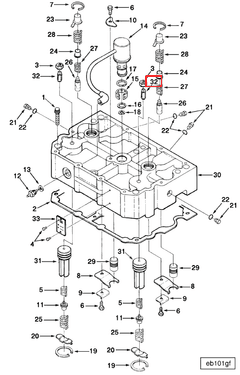

Proper installation and adjustment of the Engine Brake Adjusting Screw are vital for optimal performance. The installation process involves securing the screw in its designated position within the engine braking system, ensuring it is correctly aligned with the valve it controls. Adjustment requires turning the screw to the desired setting, which should be done in accordance with the vehicle manufacturer’s guidelines to achieve the optimal balance of engine braking force 1.

Troubleshooting Common Issues

Common issues with the Engine Brake Adjusting Screw may include improper adjustment, leading to either insufficient or excessive engine braking force. Signs of wear or malfunction can manifest as unusual engine noises or a noticeable change in the effectiveness of the engine brake. Troubleshooting steps involve checking the screw’s position and making necessary adjustments. If the screw appears damaged or worn, replacement may be required to restore proper function 1.

Maintenance Tips

To ensure the longevity and reliable performance of the Engine Brake Adjusting Screw, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage and ensuring the screw is correctly adjusted. Keeping the screw and its surrounding components clean and free from debris will also contribute to its efficient operation. Following these maintenance tips will help in preventing issues and ensuring the engine brake system operates effectively 1.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and focus on customer satisfaction underscore its position as a leader in engine component manufacturing, including the Cummins 3071593 Engine Brake Adjusting Screw 2.

Engine Brake Adjusting Screw (Part 3071593) in Cummins Engines

The Engine Brake Adjusting Screw, part number 3071593, is a critical component in the operation of Cummins engines, particularly in models that utilize engine braking systems. This screw is designed to fine-tune the engine brake mechanism, ensuring optimal performance and reliability across various engine types.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Engine Brake Adjusting Screw plays a pivotal role in the engine brake system. This screw is integral to the calibration and adjustment of the engine brake, which is essential for maintaining the desired engine braking performance. The precise adjustment of this screw ensures that the engine brake operates within the specified parameters, contributing to the overall efficiency and longevity of the engine.

The N14 MECHANICAL engines are known for their robust design and are widely used in heavy-duty applications. The Engine Brake Adjusting Screw in these engines is a testament to Cummins’ commitment to providing reliable and high-performance components. By ensuring that this screw is properly adjusted, operators can maintain the integrity of the engine brake system, leading to better fuel efficiency and reduced wear on engine components 2.

Role of Part 3071593 Engine Brake Adjusting Screw in Engine Systems

The Engine Brake Adjusting Screw (Part 3071593) is integral to the functionality of various engine systems, particularly those involving engine brakes. This component is designed to fine-tune the performance of the engine brake, ensuring optimal operation within the engine system.

Integration with Engine Brake Systems

In engine brake systems, the adjusting screw works in conjunction with the brake mechanism to modulate the braking force. It allows for precise adjustments, which are essential for maintaining the desired level of engine deceleration. This is particularly important in heavy-duty engines where consistent and reliable braking performance is required.

Interaction with Cummins Engine Brake Kits

When used with Cummins engine brake kits, the adjusting screw plays a significant role in calibrating the brake’s response. Cummins engine brake kits are known for their robust performance, and the adjusting screw ensures that the brake operates within specified parameters, enhancing both safety and efficiency.

Role in C Brake Kits

C brake kits often require meticulous tuning to achieve the best performance. The Engine Brake Adjusting Screw (Part 3071593) facilitates this by allowing engineers and mechanics to make minor adjustments that can have a substantial impact on the brake’s effectiveness. This ensures that the brake system performs reliably under various driving conditions.

Contribution to Overall Engine Control

The adjusting screw is also a key component in the overall engine control system. By fine-tuning the engine brake, it contributes to the smooth operation of the engine, reducing wear and tear on other components. This is particularly beneficial in high-stress environments where engine components are subjected to significant loads.

Enhancing Brake Kit Performance

In conjunction with adjusting screw kits, the Engine Brake Adjusting Screw ensures that the brake kit operates at peak efficiency. These kits often include multiple components that work together to provide enhanced braking performance, and the adjusting screw is a vital part of this ensemble, allowing for on-the-fly adjustments that can adapt to changing conditions.

Supporting Engine Brake Functionality

Finally, the adjusting screw supports the fundamental functionality of the engine brake. By allowing for precise adjustments, it ensures that the brake system can respond accurately to driver inputs, providing a safer and more controlled driving experience. This is especially important in applications where precise control over vehicle speed and deceleration is necessary 2.

Conclusion

The Cummins 3071593 Engine Brake Adjusting Screw is a vital component in the engine braking systems of heavy-duty trucks. Its role in modulating engine braking force contributes to the safety, efficiency, and performance of these vehicles. Proper installation, adjustment, and maintenance of this part are essential for ensuring optimal engine brake performance and longevity. Cummins’ commitment to quality and innovation is evident in the design and functionality of this screw, making it a critical component in the operation of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.