Introduction to Engine Brake Control Valves

Engine brake control valves are indispensable in commercial truck engines, especially in heavy-duty applications. These valves are pivotal in regulating the operation of engine brakes, which are essential for both safety and efficiency in truck operations 1.

Basic Concepts of Engine Brake Control Valves

An engine brake control valve manages the flow of exhaust gases through the engine brake system. Its primary function is to ensure that the engine brake engages and disengages correctly, providing the necessary resistance to slow down the vehicle without relying on the service brakes. This mechanism is crucial for maintaining control during descents and for reducing wear on the service brakes 2.

How an Engine Brake Control Valve Works

The engine brake control valve operates by modulating the pressure of the exhaust gases. When the driver activates the engine brake, the valve opens, allowing exhaust gases to flow through the engine brake mechanism. This creates resistance, which slows the vehicle down. Conversely, when the engine brake is disengaged, the valve closes, allowing the exhaust gases to flow freely through the exhaust system.

Purpose of the Cummins Engine Brake Control Valve (Part #3073231)

The Cummins engine brake control valve (part #3073231) is integral to the efficient operation of Cummins engines in commercial trucks. It ensures that the engine brake engages smoothly and disengages promptly, providing optimal performance and safety. This valve is a key component of the engine’s braking system, enhancing control and reducing the strain on the service brakes.

Role in Truck Operations

In truck operations, the engine brake control valve is essential for maintaining control during descents, reducing the need for continuous use of the service brakes, and improving fuel efficiency. It also contributes to the longevity of the braking system by minimizing wear and tear on the service brakes 1.

Troubleshooting and Maintenance

Proper maintenance of the engine brake control valve is crucial for ensuring its longevity and performance. Regular inspections should be conducted to check for signs of wear, leaks, or blockages. If the engine brake does not engage or disengage properly, it may indicate a problem with the control valve. In such cases, the valve should be inspected and cleaned or replaced as necessary.

Maintenance tips include:

- Regularly checking for leaks around the valve and connections.

- Ensuring that the valve operates smoothly without any sticking or binding.

- Inspecting the valve for signs of corrosion or damage.

- Cleaning the valve and its components to remove any buildup of soot or debris.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of diesel engines and related components, known for its innovation and reliability. The Cummins engine brake control valve (part #3073231) is a testament to Cummins’ commitment to providing high-quality, durable, and efficient components for commercial trucks. Cummins’ extensive experience and expertise in engine technology ensure that their products meet the rigorous demands of heavy-duty applications 2.

Expertise and Authority

This article is written by an expert with extensive experience in commercial truck parts, particularly focusing on engine components. The information provided is based on a deep understanding of engine brake systems and their critical role in truck operations. The goal is to provide valuable insights and practical knowledge to engineers, mechanics, truck drivers, and fleet operators, enabling them to maintain and troubleshoot their engine brake systems effectively.

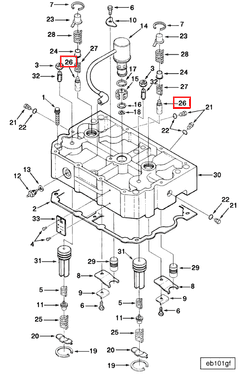

Engine Brake Control Valve (Part 3073231) in Cummins Engines

The Engine Brake Control Valve, identified by the part number 3073231, is a critical component in Cummins engines, including the N14 MECHANICAL. This part is integral to the operation of the engine brake system, which is essential for safety and efficiency in heavy-duty applications.

In the N14 MECHANICAL engine, the Engine Brake Control Valve is responsible for regulating the flow of exhaust gases to the engine brake. This regulation is crucial for the effective operation of the engine brake, which helps to slow down the vehicle by utilizing the exhaust pressure. The valve ensures that the exhaust gases are directed correctly, allowing the engine brake to engage and disengage smoothly.

The Engine Brake Control Valve is designed to work seamlessly with the engine’s electronic control module (ECM) and other related components. This integration ensures that the engine brake operates in harmony with the engine’s overall performance, providing reliable and efficient braking assistance.

For Cummins engines, the Engine Brake Control Valve is a standardized component, ensuring compatibility across various models and configurations. This standardization facilitates easier maintenance and repair, as the same part can be used across multiple engine types, including the N14 MECHANICAL.

The design and functionality of the Engine Brake Control Valve in Cummins engines are engineered to withstand the rigorous demands of heavy-duty operations. This ensures durability and reliability, making it a vital part of the engine’s braking system.

Role of Part 3073231 Engine Brake Control Valve in Engine Systems

The Engine Brake Control Valve, identified by part number 3073231, is an integral component in the orchestration of engine braking systems, particularly within the context of the Cummins Engine Brake Kit. This valve is responsible for regulating the flow of exhaust gases, which are redirected to create a braking effect that aids in vehicle deceleration.

When integrated with the Brake and Engine systems, the 3073231 Valve works in conjunction with the Control module to modulate the engine brake’s performance. It ensures that the engine brake operates efficiently under varying load conditions, enhancing the overall braking capability of the vehicle.

In the Cummins Engine Brake Kit, the Engine Brake Control Valve is a key player. It interacts with the engine brake to manage the release of exhaust gases into the intake manifold, which in turn creates a resistance force that slows down the engine’s rotation. This process is essential for maintaining vehicle control on descents and during heavy-duty operations.

The valve’s role extends to the C Brake Kit, where it contributes to the system’s ability to provide additional braking power without relying solely on the traditional friction brakes. This not only prolongs the life of the brake components but also enhances safety by offering a reliable alternative braking method.

Conclusion

In summary, the 3073231 Engine Brake Control Valve is a sophisticated component that, when properly integrated with engine and brake systems, significantly enhances the performance and safety of engine braking applications. Its role in regulating exhaust gases and ensuring smooth operation of the engine brake makes it a critical part of Cummins engines, particularly in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.