3079603

Engine Brake Adjusting Screw

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Engine Brake Adjusting Screw (Part #3079603) by Cummins is a component in the engine braking system of commercial trucks. It is designed to fine-tune the engine braking performance, ensuring optimal operation under various driving conditions. This part is integral to the efficient management of vehicle speed, particularly during descents, by modulating the engine’s resistance to rotation 1.

Function and Operation

The Engine Brake Adjusting Screw operates within the engine braking system by adjusting the valve timing to control the amount of air that bypasses the turbocharger and enters the engine cylinders. This mechanism increases the engine’s resistance to rotation, effectively slowing the vehicle without relying on the friction brakes. The screw interacts with other components of the engine braking system, such as the exhaust brake valve and the engine control module, to achieve the desired braking effect 2.

Role in Truck Operation

In the overall operation of a truck, the Engine Brake Adjusting Screw contributes to vehicle control by providing a means to manage speed during descents. This is particularly important in heavy-duty trucks, where the weight and momentum can place significant strain on the friction brakes. By utilizing engine braking, the screw helps to reduce the reliance on friction brakes, thereby enhancing safety and extending the life of the braking system. It allows drivers to maintain control of their vehicle in a more efficient and safer manner 3.

Key Features

The 3079603 is characterized by its precise design and durable construction. Made from high-quality materials, it is built to withstand the harsh conditions of commercial truck operation. Its design allows for fine adjustments to the engine braking system, ensuring that the braking force can be tailored to the specific needs of the driver and the road conditions. Additionally, the screw’s unique attributes contribute to its performance and longevity, making it a reliable component in the engine braking system.

Benefits

The Engine Brake Adjusting Screw offers several benefits, including improved fuel efficiency through reduced reliance on friction brakes. By utilizing engine braking, trucks can achieve better fuel economy, as the engine does not need to work as hard to slow down the vehicle. Furthermore, the screw contributes to extended brake life by minimizing the wear and tear on the friction brakes. This not only reduces maintenance costs but also enhances driver control during downhill driving, leading to a safer and more efficient driving experience.

Troubleshooting and Maintenance

Common issues associated with the Engine Brake Adjusting Screw may include improper adjustment, leading to either insufficient or excessive engine braking. Troubleshooting these problems involves checking the screw’s position and making necessary adjustments to ensure optimal performance. Regular maintenance, such as inspecting for wear and ensuring proper lubrication, is crucial to maintaining the screw’s functionality and longevity. Following the manufacturer’s guidelines for maintenance can help prevent issues and ensure the component operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a leader in the commercial vehicle industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s expertise in diesel engine manufacturing and its dedication to advancing technology have made it a trusted name in the industry, providing reliable and efficient solutions for a wide range of applications.

Role of Part 3079603 Engine Brake Adjusting Screw in Engine Systems

The Engine Brake Adjusting Screw is integral to the functionality of the Cummins Engine Brake Kit and the Engine Brake system. This component is designed to fine-tune the operation of the engine brake, ensuring optimal performance and efficiency.

Interaction with Cummins Engine Brake Kit

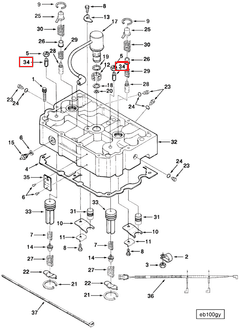

Within the Cummins Engine Brake Kit, the Engine Brake Adjusting Screw plays a significant role in modulating the brake’s response. By adjusting the screw, technicians can calibrate the engine brake to meet specific performance requirements. This adjustment affects how the engine brake engages and disengages, influencing factors such as deceleration rate and engine RPM during braking.

Contribution to Engine Brake System

In the broader Engine Brake system, the Engine Brake Adjusting Screw ensures that the brake operates within the desired parameters. It allows for precise control over the valve timing and the amount of exhaust gas recirculation, which are key to the engine brake’s effectiveness. Proper adjustment of this screw can enhance the engine’s braking power, reduce wear on the transmission, and improve overall driving safety by providing consistent and reliable braking performance.

Conclusion

The Engine Brake Adjusting Screw (3079603) is a vital component in maintaining the balance and performance of the engine brake system, facilitating smoother operation and longer component lifespan. Its role in fine-tuning engine braking performance, contributing to vehicle control, and offering benefits such as improved fuel efficiency and extended brake life, underscores its importance in the operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.