This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

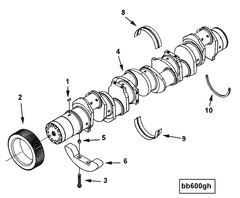

The Cummins 3089796 Engine With Gear Crankshaft is a significant component in commercial truck engines, manufactured by Cummins Inc. This crankshaft is designed to meet the demanding requirements of heavy-duty applications, ensuring reliable performance and durability in various operating conditions.

Basic Concepts of Crankshafts

A crankshaft is a mechanical part used in internal combustion engines to convert the linear motion of the pistons into rotational motion. This conversion is achieved through the crankshaft’s offset journals, which are connected to the pistons via connecting rods. As the pistons move up and down, the crankshaft rotates, driving the engine’s output shaft and ultimately powering the vehicle 1.

Role of the 3089796 Engine With Gear Crankshaft in Truck Operation

The 3089796 Engine With Gear Crankshaft plays a specific role in the operation of a commercial truck by facilitating the conversion of linear piston motion into rotational motion. This crankshaft interacts with other engine components, such as the pistons, connecting rods, and flywheel, to ensure smooth and efficient engine operation. Its gear design allows for the integration of additional engine systems, such as the timing gear and balance shaft, enhancing overall engine performance 2.

Key Features of the 3089796 Engine With Gear Crankshaft

The 3089796 Engine With Gear Crankshaft boasts several key features that contribute to its performance and durability. Its design incorporates high-quality materials, such as forged steel, to withstand the stresses of heavy-duty applications. The crankshaft’s gear design allows for the integration of timing and balance systems, while its precision machining ensures smooth operation and minimal wear. Additionally, the crankshaft’s counterweights help to balance the engine, reducing vibrations and enhancing overall performance 3.

Benefits of Using the 3089796 Engine With Gear Crankshaft

The use of the 3089796 Engine With Gear Crankshaft offers several benefits, including improved engine efficiency, reliability, and longevity. Its high-quality materials and precision machining contribute to reduced friction and wear, while its gear design allows for the integration of additional engine systems. These factors combine to enhance the overall performance and durability of the engine, providing truck operators with a reliable and efficient power source 4.

Installation and Integration

When installing and integrating the 3089796 Engine With Gear Crankshaft into a truck engine, it is important to consider compatibility with other components. Proper alignment and torque specifications must be followed to ensure a secure and efficient installation. Additionally, the crankshaft’s gear design requires careful attention to timing and balance system integration to maintain optimal engine performance.

Maintenance and Troubleshooting

To ensure the longevity and performance of the 3089796 Engine With Gear Crankshaft, regular maintenance and troubleshooting are necessary. This includes monitoring oil levels and quality, inspecting for wear or damage, and addressing any issues promptly. Common problems may include misalignment, excessive wear, or damage to the gear teeth. Diagnostic procedures should be followed to identify and address these issues, and preventive maintenance tips, such as regular oil changes and inspections, should be implemented to prolong the crankshaft’s lifespan.

Performance and Efficiency

The 3089796 Engine With Gear Crankshaft contributes to the overall performance and efficiency of the truck engine by facilitating the smooth conversion of linear piston motion into rotational motion. Its high-quality materials and precision machining reduce friction and wear, while its gear design allows for the integration of timing and balance systems. These factors combine to enhance fuel economy and power output, providing truck operators with a reliable and efficient power source.

Durability and Longevity

The durability and longevity of the 3089796 Engine With Gear Crankshaft are influenced by several factors, including material quality, design features, and maintenance practices. The use of high-quality materials, such as forged steel, ensures the crankshaft can withstand the stresses of heavy-duty applications. Its precision machining and gear design contribute to smooth operation and minimal wear, while regular maintenance and troubleshooting help to prolong its lifespan.

Cummins Inc.

Cummins Inc. is a renowned manufacturer in the engine industry, with a history of innovation and commitment to quality. The company’s reputation for producing reliable and efficient engines is built on its dedication to research and development, as well as its focus on customer satisfaction. Cummins Inc. continues to push the boundaries of engine technology, ensuring that its products meet the evolving needs of the commercial truck industry.

Compatibility and Integration

The crankshaft part 3089796 is engineered to fit precisely within the specified engine models, ensuring compatibility and seamless integration. This part is meticulously designed to meet the stringent requirements of Cummins engines, providing reliable performance and durability.

Role of Part 3089796 Engine W/GEAR Crankshaft in Engine Systems

The part 3089796 Engine W/GEAR Crankshaft is integral to the operation of the cylinder block and the overall engine system. It is responsible for converting the reciprocating motion of the pistons into rotational motion, which is then transmitted through the gearbox to drive the vehicle’s wheels.

Interaction with the Cylinder Block

Within the cylinder block, the Engine W/GEAR Crankshaft interacts with several key components:

-

Pistons and Connecting Rods: The crankshaft is connected to the pistons via the connecting rods. As the pistons move up and down within the cylinders, the connecting rods transfer this linear motion to the crankshaft, causing it to rotate.

-

Main Bearings: The crankshaft is supported within the cylinder block by main bearings. These bearings allow the crankshaft to rotate smoothly and reduce friction, ensuring efficient operation and longevity of the engine.

-

Crankcase: The crankshaft is housed within the crankcase, which is part of the cylinder block. The crankcase provides a sealed environment for the crankshaft and other internal components, protecting them from contaminants and ensuring proper lubrication.

Overall Engine System Integration

Beyond its direct interaction with the cylinder block, the Engine W/GEAR Crankshaft plays a significant role in the broader engine system:

-

Flywheel or Flexplate: The crankshaft is connected to the flywheel (in manual transmissions) or flexplate (in automatic transmissions). This component helps to smooth out the power delivery from the engine and stores rotational energy to assist in starting the engine.

-

Timing Chain or Belt: The crankshaft is synchronized with the camshaft(s) via a timing chain or belt. This ensures that the valves open and close at the correct times in relation to the pistons’ movements, maintaining the engine’s proper operation.

-

Oil Pump: Many engine designs drive the oil pump off the crankshaft. This ensures a constant supply of pressurized oil to lubricate all moving parts within the engine, reducing wear and tear.

-

Balance Shafts: In some engine designs, balance shafts are driven by the crankshaft to reduce vibrations caused by the engine’s operation. This contributes to a smoother running engine and increased comfort for the vehicle’s occupants.

Conclusion

The Engine W/GEAR Crankshaft is a fundamental component that ensures the efficient and smooth operation of the engine by coordinating the movements of various interconnected parts within the cylinder block and the entire engine system. Its role in converting linear piston motion into rotational motion, interacting with key components within the cylinder block, and integrating with the broader engine system highlights its importance in maintaining engine performance and durability.

-

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.