This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4000518 Engine Monitoring System is a sophisticated component designed to enhance the operation of commercial trucks. This system is integral to maintaining the efficiency and reliability of truck engines by continuously monitoring various engine parameters. Its role is significant in ensuring that the engine operates within optimal conditions, thereby contributing to the overall performance and longevity of the vehicle 1.

Basic Concepts of Engine Monitoring Systems

An Engine Monitoring System (EMS) is a technology that observes and records the performance of an engine in real-time. It functions by collecting data from various sensors placed throughout the engine. This data is then analyzed to assess the engine’s condition and performance. The EMS plays a role in the overall maintenance strategy by providing insights into the engine’s health, which can help in scheduling timely maintenance and preventing unexpected breakdowns 2.

Purpose of the Cummins 4000518 Engine Monitoring System

The Cummins 4000518 Engine Monitoring System is specifically designed to monitor engine parameters such as temperature, pressure, and fuel efficiency. It ensures that the engine operates within specified limits by providing real-time data to the driver and fleet managers. This system contributes to maintaining optimal engine performance and can alert operators to potential issues before they become serious problems 3.

Key Features

The Cummins 4000518 Engine Monitoring System includes several primary features that enhance its functionality. These features include real-time data collection, which allows for immediate assessment of engine conditions. It also offers diagnostic capabilities, enabling it to identify issues within the engine system. Additionally, the system integrates with other vehicle systems, providing a comprehensive view of the truck’s overall performance.

Benefits of Using the Cummins 4000518 Engine Monitoring System

Utilizing the Cummins 4000518 Engine Monitoring System offers several advantages. It contributes to improved engine efficiency by ensuring that the engine operates under optimal conditions. This system can reduce downtime by identifying issues early, allowing for timely maintenance. Moreover, it enhances safety through the early detection of potential engine problems, which can prevent accidents caused by engine failure.

Installation and Integration

Proper installation and integration of the Cummins 4000518 Engine Monitoring System into a truck’s existing setup are crucial for its optimal function. Guidelines for installation include ensuring compatibility with the truck’s engine and other systems. Integration involves connecting the system to the truck’s onboard computer and sensors, allowing for seamless data collection and analysis.

Data Interpretation and Analysis

Interpreting the data provided by the Cummins 4000518 Engine Monitoring System is key to understanding the engine’s condition. This involves analyzing diagnostic codes and performance metrics to assess engine health. Understanding these data points can help in making informed decisions regarding maintenance and operational adjustments.

Troubleshooting Common Issues

Common issues with the Cummins 4000518 Engine Monitoring System may include sensor malfunctions or data transmission errors. Troubleshooting these problems involves checking the system’s connections, ensuring sensors are functioning correctly, and verifying data transmission pathways. Solutions may range from recalibrating sensors to replacing faulty components.

Maintenance and Upkeep

Regular maintenance and upkeep of the Cummins 4000518 Engine Monitoring System are recommended to ensure its continued reliable operation. This includes periodic checks of sensors and connections, updating software as needed, and ensuring the system is calibrated correctly. Proper maintenance can extend the system’s lifespan and maintain its accuracy.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a key player in the commercial truck industry. The company’s commitment to advancing technology and improving efficiency is evident in its range of products, including the Cummins 4000518 Engine Monitoring System 4.

Integration with Cummins Engines

QSK19 CM500, QSK45 CM500, and QSK60 CM500

The Engine Monitoring System is engineered to seamlessly integrate with the QSK19 CM500, QSK45 CM500, and QSK60 CM500 engines. This integration involves the following key aspects:

-

Real-Time Data Acquisition: The system continuously monitors various engine parameters such as temperature, pressure, and fuel consumption. This data is crucial for ensuring the engine operates within its optimal parameters.

-

Diagnostic Capabilities: The Engine Monitoring System is equipped with advanced diagnostic tools that can detect potential issues before they escalate into major problems. This proactive approach helps in maintaining the engine’s longevity and performance.

-

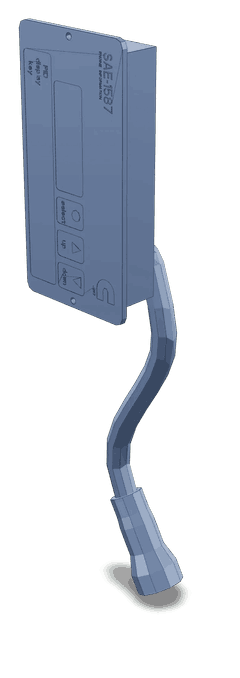

User Interface: The system provides an intuitive interface that allows operators to view real-time data and alerts. This interface is designed to be user-friendly, ensuring that even those with minimal technical expertise can understand and act on the information provided.

-

Customization: The Engine Monitoring System can be customized to meet specific operational needs. This flexibility ensures that the system can be tailored to the unique requirements of different applications, whether in heavy-duty transportation, marine, or industrial settings.

By integrating the Engine Monitoring System with the QSK19 CM500, QSK45 CM500, and QSK60 CM500 engines, Cummins ensures that these engines benefit from enhanced monitoring and diagnostic capabilities, ultimately leading to improved efficiency and reduced downtime.

Integration of Part 4000518 Engine Monitoring System with Engine Components

The part 4000518 Engine Monitoring System is designed to seamlessly integrate with various engine components to enhance performance monitoring and diagnostics. Here’s how it interfaces with key components:

Instrument Panel

The Engine Monitoring System interfaces with the instrument panel to provide real-time data on engine parameters. This integration allows for immediate feedback on engine health, performance metrics, and any anomalies that may require attention.

Digital Display Panel

When connected to the digital display panel, the Engine Monitoring System offers a user-friendly interface for engineers and mechanics. It presents critical data in an easily digestible format, enabling quick assessment and decision-making during maintenance or operation.

Engine Instrument

The system works in tandem with the engine instrument to gather detailed data on various engine functions. This includes monitoring fuel consumption, oil pressure, temperature, and other vital signs, ensuring that the engine operates within optimal parameters.

Engine Instruction Top-Level Assembly Panel

Integration with the engine instruction top-level assembly panel allows the Engine Monitoring System to provide comprehensive oversight of the engine’s operational status. This facilitates better coordination between different engine subsystems and enhances overall efficiency.

Panel

The Engine Monitoring System is designed to be compatible with various types of panels used in engine setups. Whether it’s a standard panel or a custom-designed one, the system ensures that all relevant data is accurately captured and displayed.

Arrangement

Proper arrangement of the Engine Monitoring System within the engine setup is essential for effective monitoring. It should be strategically placed to ensure it can communicate with all necessary components, providing a holistic view of engine performance.

By integrating part 4000518 Engine Monitoring System with these components, engineers and mechanics can achieve a more robust and reliable engine monitoring solution, leading to improved maintenance practices and enhanced engine performance.

Conclusion

The Cummins 4000518 Engine Monitoring System is a critical component for enhancing the operational efficiency and reliability of commercial trucks. By continuously monitoring engine parameters and providing real-time data, this system ensures that engines operate within optimal conditions, thereby contributing to the overall performance and longevity of the vehicle. Its integration with various engine components and systems allows for comprehensive monitoring and diagnostics, ultimately leading to improved maintenance practices and enhanced engine performance.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Hilgers, Michael (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Hilgers, Michael (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4358360.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.