This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4090181 Engine Piston is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the conversion of fuel energy into mechanical work, contributing significantly to the engine’s operation and overall performance. Understanding its role and significance is key to maintaining and optimizing the efficiency of heavy-duty trucks.

Basic Concepts of Engine Pistons

An engine piston is a cylindrical component that moves up and down within the engine’s cylinders. Its primary function is to compress the air-fuel mixture and, following ignition, to transfer the force of the expanding gases to the crankshaft via the connecting rod. This movement is fundamental to the engine’s operation, as it drives the vehicle’s wheels through the transmission system 1.

Role of the 4090181 Engine Piston in Truck Operation

This Cummins part plays a specific role in the operation of a truck by ensuring efficient combustion and power transmission. It interacts with other engine components such as the cylinder walls, piston rings, and connecting rod. This interaction is crucial for maintaining the engine’s seal, reducing friction, and ensuring smooth operation. The piston’s design allows for optimal fuel efficiency and power output, directly impacting the truck’s performance 2.

Key Features of the 4090181 Engine Piston

This part is characterized by its robust design and the materials used in its construction. It is made from high-strength aluminum alloys, which offer a balance of lightweight and durability. The piston features advanced cooling channels and a skirt design that enhances its performance under high-stress conditions. These characteristics contribute to its efficiency, durability, and reliability in heavy-duty applications 3.

Benefits of Using the 4090181 Engine Piston

Utilizing this part in heavy-duty trucks offers several benefits. Its design and material composition contribute to improved engine efficiency, allowing for better fuel economy. The piston’s durability ensures long-term reliability, reducing the need for frequent replacements. Additionally, its precise engineering enhances the overall performance and longevity of the engine 4.

Troubleshooting Common Issues with Engine Pistons

Common issues with engine pistons may include excessive wear, piston ring failure, or issues with the piston’s cooling system. Symptoms to watch for include unusual engine noises, decreased performance, or increased fuel consumption. Addressing these issues promptly through inspection and, if necessary, replacement or repair can help maintain the engine’s efficiency and reliability 1.

Maintenance Tips for Engine Pistons

To ensure optimal performance and longevity of engine pistons, regular maintenance is recommended. This includes routine inspections for signs of wear or damage, ensuring proper lubrication, and addressing any issues promptly. Following the manufacturer’s guidelines for maintenance and care can help prevent common problems and extend the life of the pistons 2.

The Manufacturing Process of the 4090181 Engine Piston

The manufacturing process of this part involves precision engineering and quality control measures. Cummins employs advanced manufacturing techniques to ensure the piston meets strict performance and durability standards. This process includes the careful selection of materials, precise machining, and rigorous testing to guarantee the piston’s quality and reliability 3.

Historical Development of Engine Pistons

The design and technology of engine pistons have evolved significantly over the years. Advancements in materials, manufacturing processes, and engineering have led to improvements in performance, efficiency, and durability. These developments have played a role in enhancing the capabilities of engines across various applications, including heavy-duty trucks 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the automotive industry, Cummins is renowned for its high-quality engine components, including pistons. The company’s commitment to innovation, quality, and customer satisfaction has established it as a trusted name in the production of engine parts.

Compatibility of 4090181 with Cummins Engines

This part is designed to fit seamlessly within a range of Cummins diesel engines, ensuring optimal performance and reliability. It is compatible with several models, including:

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

These engines are known for their robust construction and efficiency, making them suitable for various industrial applications. This part is engineered to meet the specific demands of these engines, providing a perfect balance of durability and performance.

Role of 4090181 in Engine Systems

This part is integral to the operation of various engine systems, working in concert with multiple components to ensure efficient and reliable performance.

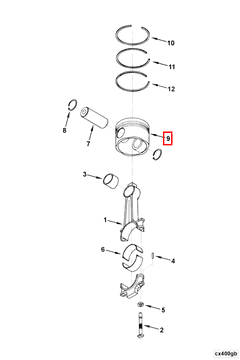

Interaction with the Connecting Rod and Piston

This part interfaces directly with the connecting rod. This connection is vital for transferring the force generated by the combustion process in the cylinder to the crankshaft, thereby converting linear motion into rotational motion. The precision fit between the piston and the connecting rod ensures minimal friction and maximum efficiency.

Coordination with the Cylinder Head

Above the Engine Piston lies the cylinder head, which houses the valves and spark plug (in gasoline engines) or the fuel injector (in diesel engines). The piston’s movement is synchronized with the opening and closing of these valves to allow for the intake of air-fuel mixture and the expulsion of exhaust gases. Proper sealing between the piston and the cylinder head is essential to maintain compression and prevent leaks.

Integration with the Camshaft and Camshaft Mounting

The camshaft, mounted via the camshaft mounting, controls the timing of the valve operation. The Engine Piston’s movement must be precisely timed with the camshaft’s rotation to ensure that the valves open and close at the correct moments in the engine cycle. This synchronization is fundamental for optimal engine performance and efficiency.

Role in the Engine Top Level Assembly Piston

In the engine top-level assembly, the Engine Piston is a key component. It works alongside other parts such as the liner kit and overhaul kit to form a cohesive system. The liner kit provides the piston with a smooth surface to move against, reducing wear and enhancing durability. The overhaul kit often includes additional components like gaskets and seals that work with the piston to maintain the integrity of the combustion chamber.

Contribution to Engine Performance

The performance of the engine is heavily influenced by the condition and fit of the Engine Piston. A well-maintained piston, such as part 4090181, ensures smooth operation, efficient combustion, and consistent power delivery. It also plays a role in thermal management, dissipating heat away from the combustion chamber to prevent overheating.

Relationship with the Piston and Connecting Rod Assembly

The Engine Piston is part of a larger assembly that includes the piston and connecting rod. This assembly is responsible for the primary motion within the engine, translating the energy from combustion into mechanical work. The integrity and balance of this assembly are paramount for the engine’s longevity and performance.

Conclusion

The Cummins 4090181 Engine Piston is a critical component in the operation of heavy-duty truck engines, ensuring efficient combustion and power transmission. Its robust design, advanced features, and compatibility with specific Cummins engine models make it a reliable choice for maintaining and optimizing engine performance. Regular maintenance and understanding its role within the engine system are essential for maximizing the efficiency and longevity of heavy-duty trucks.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ ↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ ↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ ↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.