This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4095750 Engine Lifting Bracket is a specialized component designed for use in heavy-duty truck maintenance and operation. This part plays a significant role in facilitating the safe and efficient removal and installation of Cummins engines. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, ensuring that engine servicing processes are conducted with precision and safety 1.

Purpose and Function

The Cummins 4095750 Engine Lifting Bracket is integral to the operation of heavy-duty trucks by providing a secure attachment point for lifting equipment during engine removal and installation. It simplifies the process by offering a stable and reliable connection, which is crucial for maintaining the integrity of the engine and surrounding components during servicing. This Cummins part ensures that the engine can be handled with minimal risk of damage or injury 2.

Key Features

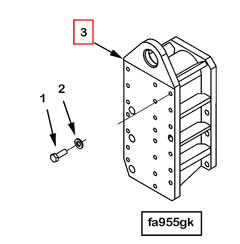

The Cummins 4095750 Engine Lifting Bracket is characterized by its robust design and high-quality materials. It is engineered to offer exceptional durability and strength, capable of withstanding the significant stresses associated with heavy-duty engine lifting. The bracket is specifically designed to be compatible with Cummins engines, ensuring a precise fit and optimal performance. Its construction includes features that enhance its resilience and longevity, making it a reliable component in demanding environments 3.

Benefits

Utilizing the Cummins 4095750 Engine Lifting Bracket offers several advantages. It enhances safety during engine handling by providing a secure attachment point, reducing the risk of accidents. The bracket also contributes to a reduction in maintenance time, as it streamlines the engine removal and installation processes. Furthermore, it improves overall efficiency in engine servicing, allowing for quicker and more reliable operations.

Installation Process

Installing the Cummins 4095750 Engine Lifting Bracket involves several steps to ensure proper functionality and safety. First, the engine bay must be prepared by ensuring there is adequate space and that all necessary tools are available. The bracket should be positioned according to the manufacturer’s guidelines, ensuring it is aligned correctly with the engine’s lifting points. Secure the bracket using the recommended fastening methods, which may include bolts or other securing mechanisms. It is important to verify that the bracket is firmly in place and that all connections are tight before proceeding with engine lifting operations.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 4095750 Engine Lifting Bracket, regular maintenance is recommended. This includes inspecting the bracket for any signs of wear or damage, ensuring that all fastenings remain secure, and cleaning the bracket to remove any debris or corrosion. Common issues may include loosening of bolts or wear on the bracket itself. Troubleshooting these issues typically involves re-tightening fasteners or, in more severe cases, replacing the bracket to maintain safety and efficiency.

Safety Considerations

When using the Cummins 4095750 Engine Lifting Bracket, several safety practices should be observed. It is important to ensure proper load distribution and to adhere to the weight limits specified by the manufacturer. Operators should use appropriate lifting equipment and follow established safety protocols to prevent accidents. Additionally, all personnel involved in the engine lifting process should be trained in the correct use of the bracket and aware of the potential hazards associated with heavy-duty engine handling.

Cummins Overview

Cummins Inc. is a renowned leader in the automotive and heavy-duty truck industry, with a rich history of innovation and quality in engine component manufacturing. Founded in 1919, Cummins has built a reputation for delivering reliable and high-performance engine solutions. The company’s commitment to quality is evident in its rigorous testing and manufacturing processes, ensuring that each component, including the Cummins 4095750 Engine Lifting Bracket, meets the highest standards of durability and performance.

Engine Lifting Bracket 4095750 Compatibility

The Cummins Engine Lifting Bracket, part number 4095750, is a critical component designed to facilitate the safe and efficient lifting of specific engine models. This bracket is engineered to provide robust support during maintenance, installation, and removal processes, ensuring that the engine is handled with precision and care.

QSK23 and CM2350 Engines

The Engine Lifting Bracket 4095750 is specifically designed to fit the Cummins QSK23 and CM2350 engines. These engines are known for their high power output and reliability, often used in heavy-duty applications such as construction equipment, marine vessels, and power generation. The bracket’s design ensures it can withstand the stresses associated with these demanding environments, providing a secure attachment point for lifting equipment.

K127 Engine

Similarly, the Cummins K127 engine benefits from the use of the Engine Lifting Bracket 4095750. This engine is typically employed in a variety of industrial applications, including agricultural machinery and transportation. The bracket’s compatibility with the K127 engine ensures that it can be lifted and moved with ease, minimizing the risk of damage and ensuring the safety of personnel involved in the process.

Grouping by Application

In industrial and heavy-duty applications, the use of the Engine Lifting Bracket 4095750 is crucial. Whether it’s for the QSK23 and CM2350 engines used in construction and marine sectors or the K127 engine found in agricultural and transportation industries, this bracket provides a standardized solution for engine handling. Its design allows for easy integration into existing lifting procedures, enhancing operational efficiency and safety.

Role of Part 4095750 Engine Lifting Bracket in Engine Systems

The 4095750 Engine Lifting Bracket is an integral component in the arrangement and maintenance of various engine systems. Its primary function is to provide a secure and stable platform for lifting and positioning the engine during installation, removal, or maintenance procedures.

Integration with Engine Arrangement

In the context of engine arrangement, the 4095750 Bracket ensures that the engine is properly aligned and supported. This is particularly important during the initial setup or when re-installing the engine after maintenance. The bracket helps in maintaining the correct orientation and balance, which is essential for the engine’s optimal performance and longevity.

Facilitation of Engine Lifting

During the lifting process, the 4095750 Bracket plays a significant role in distributing the engine’s weight evenly. This even distribution is vital to prevent any undue stress on specific parts of the engine, which could lead to damage. The bracket’s design allows for safe and efficient lifting, reducing the risk of accidents and ensuring that the engine remains intact throughout the process.

Interaction with Fan Drive and Fan Drive Mounting

The 4095750 Bracket also interacts with the fan drive and its mounting. When the engine is lifted, the bracket must accommodate the fan drive’s position and ensure that it does not interfere with the lifting process. This is important for maintaining the integrity of the fan drive system, which is responsible for cooling the engine. Proper alignment and support provided by the bracket help in preserving the functionality of the fan drive and its mounting, ensuring that the cooling system operates efficiently once the engine is in place.

Conclusion

In summary, the Cummins 4095750 Engine Lifting Bracket is a key component in the safe and effective handling of engine systems. Its role in the arrangement, lifting, and interaction with other components like the fan drive and its mounting underscores its importance in engine maintenance and installation procedures.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Bennett, Sean and Norman, Ian Andrew. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.