This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

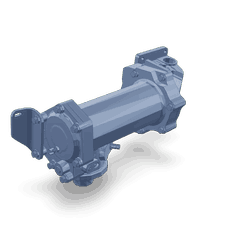

The Cummins 4296439 Engine Oil Cooler is a component designed to maintain optimal engine oil temperature in commercial trucks. Its role is significant in ensuring the efficient operation and longevity of the engine. By regulating oil temperature, it contributes to the overall performance and reliability of the vehicle.

Basic Concepts of Engine Oil Coolers

An engine oil cooler is a device that helps regulate the temperature of engine oil. It functions by transferring excess heat from the oil to the surrounding air or coolant, depending on the design. This process is based on the principles of heat exchange, where a fluid (in this case, engine oil) passes through a series of tubes or fins that are exposed to a cooler medium, facilitating the dissipation of heat 1.

Purpose of the Cummins 4296439 Engine Oil Cooler

This Cummins part plays a role in maintaining optimal engine oil temperature. By ensuring that the oil remains within a specified temperature range, it helps in achieving efficient engine performance. This regulation is vital for preventing overheating, which can lead to engine damage, and for prolonging the engine’s operational life 2.

Key Features

The 4296439 is characterized by its robust design and the use of high-quality materials. These attributes contribute to its performance and durability. The cooler is engineered to withstand the demanding conditions typical of commercial truck operations, ensuring reliable performance over time 3.

Benefits of Using the Cummins 4296439 Engine Oil Cooler

Utilizing this part offers several advantages. It contributes to improved engine efficiency by maintaining optimal oil viscosity. This, in turn, reduces the risk of overheating and enhances overall engine reliability. The cooler also plays a part in extending the engine’s lifespan by preventing thermal stress 4.

Installation and Integration

Proper installation of this part is crucial for its effective operation. It is designed to be compatible with various truck models, ensuring seamless integration within the engine cooling system. Following manufacturer guidelines during installation helps in maximizing the cooler’s performance and ensuring system compatibility.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and effectiveness of this Cummins part. This includes periodic inspections for signs of wear or damage and ensuring that all connections are secure. Common troubleshooting tips involve checking for leaks, verifying proper coolant flow, and addressing any unusual noises or performance issues promptly.

Performance in Various Operating Conditions

This part is designed to perform effectively under a range of operating conditions. Whether facing extreme temperatures or heavy-duty applications, it contributes to maintaining optimal engine oil temperature. This consistent performance is crucial for ensuring that the engine operates efficiently and reliably, regardless of the external conditions.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for producing high-quality engine components. The company’s commitment to excellence is evident in its product line, including the 4296439 Engine Oil Cooler. Cummins’ focus on innovation and quality ensures that its components meet the demanding requirements of commercial truck applications.

Engine Oil Cooler (Part 4296439) Compatibility with Cummins Engines

The Engine Oil Cooler part 4296439, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This cooler is essential for maintaining optimal oil temperature, ensuring efficient engine performance and longevity. Below are the Cummins engines that are compatible with this specific oil cooler:

N14 MECHANICAL

The N14 MECHANICAL engine benefits from the precise cooling capabilities of the 4296439 oil cooler. This engine, known for its robust construction and reliability, is often used in heavy-duty applications where consistent cooling is crucial.

QSNT14 CM876 N102

The QSNT14 CM876 N102 engine also integrates the 4296439 oil cooler effectively. This engine variant is designed for high-performance applications, and the oil cooler plays a pivotal role in managing the thermal load, ensuring the engine operates within safe temperature parameters.

Compatibility Summary

The 4296439 Engine Oil Cooler is engineered to fit the following Cummins engines:

- N14 MECHANICAL

- QSNT14 CM876 N102

These engines, while distinct in their specific applications and configurations, share a common requirement for effective oil cooling. The 4296439 part meets this requirement by providing reliable and efficient cooling, contributing to the overall performance and durability of the engines.

Role of Part 4296439 Engine Oil Cooler in Engine Systems

The Engine Oil Cooler (part 4296439) is an essential component in maintaining the optimal operating temperature of engine oil. This is achieved through a heat exchange process where the oil, after circulating through the engine, passes through the cooler. The cooler typically consists of a series of small tubes or fins that increase the surface area, allowing for more efficient heat dissipation.

Interaction with the Lubricating Oil Filter

Once the oil has been cooled, it returns to the engine and passes through the Lubricating Oil Filter. The filter’s role is to remove contaminants and debris that have been picked up by the oil during its journey through the engine. By ensuring that the oil is both cool and clean, the efficiency and longevity of the engine are significantly enhanced.

Enhanced Engine Performance

The integration of the Engine Oil Cooler with the Lubricating Oil Filter creates a synergistic effect that contributes to enhanced engine performance. Cooler oil reduces the risk of thermal breakdown, which can lead to increased viscosity and decreased lubricating properties. Meanwhile, the filter ensures that the oil remains free from particles that could cause abrasive wear on engine components.

Maintenance of Optimal Viscosity

Maintaining the oil at an optimal temperature also helps in preserving its viscosity. Proper viscosity is essential for the oil to form an effective lubricating film between moving parts, reducing friction and wear. The Engine Oil Cooler plays a significant role in this process by ensuring that the oil does not overheat, which could otherwise lead to a decrease in viscosity and compromised lubrication.

Reduction of Thermal Stress

By effectively managing the temperature of the engine oil, the Engine Oil Cooler also helps in reducing thermal stress on engine components. This is particularly important in high-performance or high-load applications where the engine operates under extreme conditions. The cooler ensures that the oil remains within its optimal temperature range, thereby protecting the engine from potential damage due to overheating.

Contribution to Overall Engine Efficiency

The efficient operation of the Engine Oil Cooler, in conjunction with the Lubricating Oil Filter, contributes to the overall efficiency of the engine. By ensuring that the oil is both cool and clean, these components help in maintaining the engine’s performance, reducing the likelihood of premature wear and extending the engine’s service life.

Conclusion

The Cummins 4296439 Engine Oil Cooler is a vital component in the maintenance of optimal engine oil temperature, contributing to the efficient operation and longevity of commercial truck engines. Its robust design, compatibility with various Cummins engines, and the synergistic effect with the Lubricating Oil Filter enhance engine performance and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.