This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

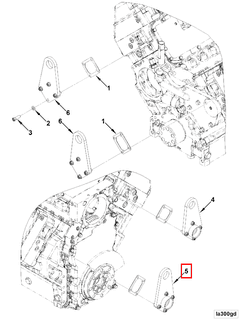

The Cummins 4308050 Engine Lifting Bracket is a specialized component designed for the maintenance and operation of heavy-duty trucks. This part is integral to the process of safely and efficiently removing and installing engines, playing a significant role in the overall maintenance strategy for these vehicles.

Purpose and Function

The Cummins 4308050 Engine Lifting Bracket facilitates the removal and installation of engines by providing a secure attachment point for lifting equipment. It ensures that the engine can be handled with precision and safety, distributing the weight evenly to reduce the risk of damage during the lifting process 1.

Key Features

This Cummins part is characterized by high-quality materials and robust structural integrity. Typically made from durable steel, it offers resistance to wear and corrosion. The bracket features a sturdy frame that can withstand significant loads, ensuring reliable performance during engine handling. Its design includes precise attachment points that align with standard lifting equipment, enhancing functionality and ease of use 2.

Benefits

Utilizing the Cummins 4308050 Engine Lifting Bracket enhances safety during engine handling by providing a secure and stable lifting point, reducing the risk of accidents and injuries. It also improves efficiency in maintenance procedures by streamlining the engine removal and installation processes, potentially leading to cost savings by minimizing downtime and reducing the need for repairs due to mishandling 3.

Installation Process

Proper installation of the Cummins 4308050 Engine Lifting Bracket involves ensuring the truck is on a level surface and the engine is securely supported. Use appropriate tools such as wrenches and torque wrenches to attach the bracket to the engine according to the manufacturer’s specifications. It is important to follow recommended procedures and safety precautions, such as wearing personal protective equipment and ensuring all connections are tight and secure 4.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4308050 Engine Lifting Bracket is essential to ensure its longevity and reliable performance. Inspect the bracket for signs of wear, corrosion, or damage before each use. Clean the bracket and its attachment points to remove any debris or contaminants that could affect its functionality. Common issues may include loose connections or damaged components, which can be addressed by tightening bolts or replacing worn parts. Preventive measures such as applying corrosion-resistant coatings can further enhance the bracket’s durability 5.

Compatibility and Usage

The Cummins 4308050 Engine Lifting Bracket is designed for use with specific types of engines and truck models. Its application extends to various maintenance scenarios, including routine engine replacements, repairs, and inspections. Understanding the compatibility of the bracket with your specific engine and truck model is important to ensure optimal performance and safety 6.

Safety Considerations

When using the Cummins 4308050 Engine Lifting Bracket, it is important to adhere to safety protocols and best practices. This includes following the manufacturer’s guidelines for installation and use, as well as maintaining a safe working environment. Ensure that all personnel involved in the engine handling process are trained and aware of the safety procedures. Regularly inspect the lifting equipment and bracket for any signs of wear or damage to prevent accidents 7.

Cummins Overview

Cummins Inc. is a renowned leader in the automotive and heavy-duty truck industry, with a rich history of innovation and quality in engine component manufacturing. The company is committed to delivering reliable and high-performance parts that meet the demanding requirements of heavy-duty applications. Cummins’ reputation for excellence is built on a foundation of rigorous testing, advanced engineering, and a dedication to customer satisfaction 8.

Compatibility with Cummins Engines

The Cummins Engine Lifting Bracket part number 4308050 is designed to be compatible with a range of Cummins engines. This bracket is an essential component for the safe and efficient removal and installation of the engine during maintenance or replacement procedures.

For the VTA903 and CM2250 engines, the 4308050 bracket provides a secure mounting point, ensuring that the engine can be lifted without risk of damage to the engine or surrounding components. This bracket is engineered to withstand the stresses associated with engine lifting, providing a reliable solution for heavy machinery operators and technicians.

Similarly, the V105 engine also benefits from the use of the 4308050 bracket. This part is crafted to fit seamlessly with the V105, facilitating straightforward engine handling. The bracket’s design allows for easy attachment and detachment, streamlining the maintenance process and reducing downtime 9.

Conclusion

In summary, the Cummins Engine Lifting Bracket part number 4308050 is a versatile and robust solution for the VTA903, CM2250, and V105 engines, ensuring that engine maintenance is conducted with the highest level of safety and efficiency.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2670 X121B, Bulletin Number 5504453.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2670 X121B, Bulletin Number 5504453.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2670 X121B, Bulletin Number 5504453.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.