This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

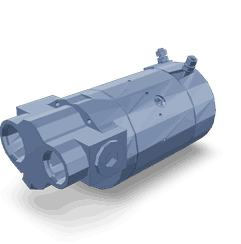

The Cummins 4312874 Engine Lubricating Primer Pump is designed to facilitate the start-up process of heavy-duty diesel engines by ensuring that critical components are adequately lubricated before the engine begins operation. This part plays a significant role in the overall performance and longevity of the engine by providing necessary lubrication to vital parts, thereby reducing wear and tear during the initial stages of engine operation 2.

Basic Concepts of Engine Lubricating Primer Pumps

An engine lubricating primer pump is a device used in diesel engines to prime the fuel system with lubricant before the engine starts. This process involves circulating oil through the engine’s lubrication system to ensure that all moving parts are coated with oil, which reduces friction and wear 3. The primer pump typically operates manually or automatically and is an integral part of the engine’s lubrication system, contributing to smoother starts and enhanced engine protection.

Purpose of the Cummins 4312874 Engine Lubricating Primer Pump

The Cummins 4312874 Engine Lubricating Primer Pump is specifically designed to prepare the engine for start-up by ensuring that essential components, such as the crankshaft, camshaft, and bearings, are properly lubricated. This pre-lubrication is vital for minimizing friction and wear during the initial moments of engine operation, which can be particularly stressful for the engine. By facilitating this process, the primer pump contributes to the overall efficiency and reliability of the engine 4.

Key Features

The Cummins 4312874 Engine Lubricating Primer Pump features a robust design that incorporates high-quality materials to ensure durability and reliability. Key features include a precision-machined housing, corrosion-resistant components, and a reliable sealing mechanism to prevent oil leaks. Additionally, the pump is engineered to operate efficiently under a range of conditions, providing consistent performance in various heavy-duty applications 1.

Benefits of Using the Cummins 4312874 Engine Lubricating Primer Pump

Utilizing the Cummins 4312874 Engine Lubricating Primer Pump offers several advantages. These include improved engine longevity due to reduced wear on critical components, enhanced engine performance through efficient lubrication, and easier engine start-ups, particularly in cold weather conditions. The pump also contributes to overall engine reliability by ensuring that the lubrication system is primed and ready for operation.

Installation Process

Installing the Cummins 4312874 Engine Lubricating Primer Pump involves several steps. First, ensure that the engine is turned off and cooled down. Disconnect the battery to prevent any electrical issues. Locate the primer pump on the engine and remove the old pump if replacing an existing one. Install the new pump by aligning it with the mounting brackets and securing it in place. Connect any necessary hoses or wiring, ensuring all connections are tight and secure. Finally, reconnect the battery and test the pump to ensure it operates correctly.

Troubleshooting Common Issues

Common issues with engine lubricating primer pumps may include difficulty in priming, leaks, or failure to operate. To troubleshoot these problems, first, check for any visible signs of damage or wear on the pump and its connections. Ensure that all hoses and wiring are correctly connected and secure. If the pump is not priming, verify that there is adequate oil in the system and that there are no obstructions in the lubrication pathways. Consulting the manufacturer’s guidelines can provide additional troubleshooting steps specific to the Cummins 4312874 model.

Maintenance Tips

Regular maintenance of the Cummins 4312874 Engine Lubricating Primer Pump is essential for ensuring its longevity and efficient operation. This includes periodic inspection of the pump and its connections for signs of wear or damage, ensuring that all seals and gaskets are intact, and verifying that the pump operates smoothly without leaks. Additionally, following the manufacturer’s recommended service intervals for oil changes and system inspections can help maintain the pump’s performance and reliability.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and diesel engine industry. The company’s product range includes engines, filtration, emissions solutions, and power generation equipment, serving customers in over 190 countries and territories worldwide.

Cummins Engine Lubricating Primer Pump 4312874 Compatibility

The Cummins Engine Lubricating Primer Pump part number 4312874 is designed to be compatible with a range of Cummins engines, ensuring efficient lubrication and priming functions. This part is integral to the engine’s operation, facilitating the initial lubrication of engine components during startup and ensuring continuous lubrication throughout the engine’s operation.

QSK95 Engines

The QSK95 series engines, known for their robust performance and reliability, are well-suited for the 4312874 primer pump. This part ensures that the engine’s lubrication system is primed effectively, reducing wear and tear and extending the engine’s lifespan.

CM2350 Engines

The CM2350 engines, which are part of Cummins’ medium-duty engine lineup, also benefit from the 4312874 primer pump. This component is engineered to provide consistent lubrication, ensuring smooth engine operation and reliability in various applications.

K113 Engines

The K113 engines, another variant in Cummins’ portfolio, are designed for heavy-duty applications. The 4312874 primer pump is crucial for these engines, as it ensures that the lubrication system is primed and maintained, supporting the engine’s performance under demanding conditions.

By integrating the 4312874 primer pump into these engines, Cummins ensures that the lubrication system operates efficiently, contributing to the overall reliability and longevity of the engines.

Role of Part 4312874 Engine Lubricating Primer Pump in Engine Systems

The part 4312874 Engine Lubricating Primer Pump is an integral component in the efficient operation of engine systems. Its primary function is to ensure that the engine’s lubrication system is adequately primed before startup. This is achieved by circulating oil through the engine’s critical components, such as the crankshaft, camshaft, and bearings, to create a protective film that reduces friction and wear 2.

When integrated with the primer system, the 4312874 pump facilitates the initial flow of oil, ensuring that all moving parts are coated with lubricant before the engine reaches operating speed. This is particularly important in high-performance or high-stress engines where immediate lubrication is essential to prevent damage.

In conjunction with the engine lubricating system, the primer pump plays a role in maintaining consistent oil pressure throughout the engine’s operation. By ensuring that oil is distributed evenly, the pump helps in cooling the engine, cleaning internal components by carrying away contaminants, and sealing combustion chambers to improve efficiency 3.

The effective use of the 4312874 Engine Lubricating Primer Pump in these systems not only enhances the engine’s performance but also contributes to its longevity by minimizing the risk of mechanical failure due to inadequate lubrication 4.

Conclusion

The Cummins 4312874 Engine Lubricating Primer Pump is a critical component for the efficient and reliable operation of heavy-duty diesel engines. By ensuring that essential components are adequately lubricated before engine start-up, this part plays a significant role in reducing wear and tear, enhancing engine performance, and extending engine longevity. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

-

The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Giancarlo Genta and Lorenzo Morello, Springer, 2019.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ ↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003.

↩ ↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.