This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

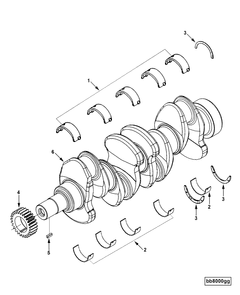

The Cummins 4941136 Engine Crankshaft Assembly is a critical component in the engine systems of commercial trucks. It converts the linear motion of the pistons into rotational motion, which is essential for driving the vehicle. This assembly is vital for the efficient and reliable operation of truck engines, contributing to overall performance and durability.

Basic Concepts of Engine Crankshaft Assembly

Engine crankshaft assemblies are fundamental to an engine’s power generation system. They convert the linear motion of the pistons, driven by the combustion process, into rotational motion. This motion is then transmitted through the transmission to the wheels, propelling the vehicle forward. The crankshaft interacts with various engine components, including the pistons, connecting rods, and the flywheel, to ensure smooth and efficient engine operation 1.

Purpose of the 4941136 Engine Crankshaft Assembly

The 4941136 Engine Crankshaft Assembly facilitates the conversion of linear piston motion into rotational motion, contributing to engine performance by ensuring efficient power transmission and supporting the engine’s balance and stability. Its design and construction aim to enhance engine efficiency and reliability, which are essential for the demanding conditions under which commercial trucks often operate 2.

Key Features

The Cummins 4941136 Engine Crankshaft Assembly is characterized by its robust design and the use of high-quality materials. These features are intended to enhance its durability and performance. The assembly may include precision-balanced components to reduce vibrations and wear, and it is engineered to withstand the high stresses and temperatures encountered in commercial truck engines. Unique attributes such as advanced coatings or specific design elements may further improve its functionality and longevity 3.

Benefits

The advantages offered by the 4941136 Engine Crankshaft Assembly include improved engine performance, increased durability, and enhanced reliability. By efficiently converting and transmitting power, this assembly contributes to the overall efficiency of the engine. Its durable construction is designed to withstand the rigors of commercial use, providing long-term reliability. Additionally, the precise engineering of the assembly helps in reducing engine vibrations and wear, leading to smoother operation and potentially lower maintenance costs.

Installation Process

Proper installation of the 4941136 Engine Crankshaft Assembly involves several steps to ensure it functions correctly within the engine. It is important to follow manufacturer guidelines for torque specifications and alignment to prevent damage and ensure optimal performance. The process includes preparing the engine block, carefully positioning the crankshaft, and securing it in place with the appropriate fasteners. Attention to detail during installation is crucial for the assembly’s performance and longevity.

Maintenance Tips

To ensure the optimal performance and longevity of the 4941136 Engine Crankshaft Assembly, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring proper lubrication, and addressing any issues promptly. Maintaining the correct oil levels and quality is particularly important, as lubrication plays a significant role in the assembly’s operation and durability. Following the manufacturer’s maintenance schedule and guidelines can help in preserving the assembly’s condition and performance.

Troubleshooting Common Issues

Typical problems that may arise with the 4941136 Engine Crankshaft Assembly include misalignment, wear, and lubrication issues. Misalignment can lead to increased wear and reduced efficiency, while wear may result from insufficient lubrication or operational stress. Lubrication issues can arise from using the wrong type of oil or failing to maintain proper oil levels. Identifying these problems early and taking corrective action, such as realigning components, replacing worn parts, or adjusting lubrication, can help in maintaining the assembly’s performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the industry for producing reliable and efficient engines. The company’s commitment to quality and innovation is evident in its product offerings, including the 4941136 Engine Crankshaft Assembly, which is designed to meet the demanding requirements of commercial truck applications.

Engine Crankshaft Assembly Part 4941136 Compatibility

The Engine Crankshaft Assembly part 4941136, manufactured by Cummins, is designed to fit seamlessly with specific models of the QSB3.3 series engines. This part is integral to the engine’s operation, converting the linear motion of the pistons into rotational motion, thereby driving the engine’s output shaft.

QSB3.3 Series Compatibility

- QSB3.3 CM2150

- QSB3.3 CM2250 EC

These engines are part of the Cummins QSB series, known for their reliability and performance in various applications. The crankshaft assembly part 4941136 is engineered to ensure compatibility with these models, providing a robust and efficient power transfer mechanism.

The part’s design and specifications are tailored to meet the demands of these engines, ensuring smooth operation and longevity. It is crucial to verify the compatibility of this crankshaft assembly with the specific engine model to ensure proper fitment and performance.

Role of Part 4941136 Engine Crankshaft Assembly in Engine Systems

The part 4941136 Engine Crankshaft Assembly is integral to the operation of the engine block and cylinder system. It is responsible for converting the linear motion of the pistons into rotational motion, which is then transmitted to the transmission system.

Interaction with the Engine Block

The crankshaft assembly is housed within the engine block, where it interacts with several key components. The main bearings within the block support the crankshaft, allowing it to rotate smoothly. The crankshaft’s journals are precision-machined to ensure a snug fit within these bearings, minimizing friction and wear. As the crankshaft rotates, it drives the connecting rods, which are attached to the pistons.

Coordination with Cylinders

Each cylinder in the engine houses a piston that moves up and down in response to the combustion process. The connecting rods link the pistons to the crankshaft. As the pistons move, they push and pull on the connecting rods, which in turn rotate the crankshaft. This rotational motion is essential for the engine’s operation, as it drives the flywheel and ultimately the transmission.

The crankshaft’s design, including its counterweights and balance shafts, helps to manage the forces generated by the pistons’ movement. This balance is vital for smooth engine operation and longevity of the engine components.

Conclusion

In summary, the part 4941136 Engine Crankshaft Assembly plays a significant role in coordinating the movement between the engine block and cylinders, ensuring efficient and reliable engine performance. Its robust design, compatibility with specific engine models, and precise engineering contribute to the overall efficiency and durability of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.