This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

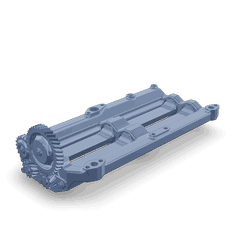

The Cummins 4944353 Engine Balancer is designed to enhance the performance and stability of heavy-duty truck engines. Its role is to mitigate vibrations and ensure smoother engine operation, contributing to overall engine efficiency and longevity. Understanding its function and significance is essential for maintaining optimal engine performance in demanding applications.

Basic Concepts of Engine Balancers

An engine balancer, also known as a harmonic balancer, reduces vibrations caused by the reciprocating motion of the engine’s components. It functions by counteracting the forces generated during engine operation, which can lead to instability and increased wear. The balancer typically consists of a weighted component that rotates with the crankshaft, helping to maintain engine stability and performance 1.

Purpose of the Cummins 4944353 Engine Balancer

The Cummins 4944353 Engine Balancer reduces vibrations that occur due to the engine’s reciprocating parts. This reduction in vibrations leads to smoother engine operation, which can enhance overall performance and reduce stress on engine components. By ensuring a balanced engine, this component contributes to a more stable and efficient running engine.

Key Features

The Cummins 4944353 Engine Balancer is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typical of heavy-duty truck applications. Unique features may include a precision-balanced weight and a durable construction that ensures longevity and reliable performance.

Benefits of Using the Cummins 4944353 Engine Balancer

Incorporating the Cummins 4944353 Engine Balancer into a truck engine setup offers several advantages. These include improved engine performance through reduced vibrations, decreased wear and tear on engine components, and potentially enhanced fuel efficiency due to smoother engine operation. These benefits contribute to the overall reliability and efficiency of the engine.

Installation Process

Installing the Cummins 4944353 Engine Balancer involves several steps to ensure proper fitting and function. The process requires specific tools and equipment, and it is important to follow safety precautions. Detailed instructions should be consulted to ensure the balancer is correctly aligned and secured, which is crucial for its effective operation and the engine’s stability.

Common Issues and Troubleshooting

Users may encounter issues with the Cummins 4944353 Engine Balancer, such as imbalance or wear. Troubleshooting these problems involves checking for proper installation, inspecting for damage, and ensuring all connections are secure. Addressing these issues promptly can help maintain the balancer’s effectiveness and the engine’s performance.

Maintenance Tips

Regular maintenance of the Cummins 4944353 Engine Balancer is important for its optimal performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning to remove any buildup that could affect its operation, and ensuring all connections remain tight. Adhering to these maintenance practices can help prevent issues and ensure the balancer continues to function effectively.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the industry for producing high-quality engine components. The company is known for its commitment to innovation and quality, which is reflected in its wide range of products designed for various applications, including heavy-duty trucks. Cummins’ dedication to excellence ensures that its components, like the 4944353 Engine Balancer, meet the demanding requirements of their intended use 2.

Compatibility with Cummins Engines

The Cummins Engine Balancer part number 4944353 is designed to ensure smooth engine operation by balancing the rotational forces within the engine. This part is compatible with several Cummins engine models, enhancing their performance and longevity.

B3.3 Engines

The B3.3 engine series benefits significantly from the use of the 4944353 Engine Balancer. This part helps mitigate vibrations and reduces wear on engine components, ensuring optimal performance and reliability.

QSB3.3 Engines

Similarly, the QSB3.3 engines are designed to perform better with the 4944353 Engine Balancer. This balancer is engineered to work seamlessly with the QSB3.3’s architecture, providing a stable and smooth running engine.

CM2250 EC Engines

The CM2250 EC engine series also integrates the 4944353 Engine Balancer effectively. This balancer is crucial for maintaining the engine’s balance, especially under varying load conditions, ensuring consistent performance and reducing the risk of mechanical failures.

QSB3.3 CM2250 EC Engines

For the combined QSB3.3 CM2250 EC engines, the 4944353 Engine Balancer is a vital component. It ensures that the engine operates within its designed parameters, providing a stable and efficient power source. This balancer is specifically tailored to handle the unique demands of these combined engine models, ensuring longevity and reliability.

Role of Part 4944353 Engine Balancer in Engine Systems

The part 4944353 Engine Balancer is a vital component in maintaining the equilibrium of various engine systems. It works in conjunction with several key components to ensure smooth operation and longevity of the engine.

Interaction with the Crankshaft

The Engine Balancer is directly connected to the crankshaft. Its primary function is to counteract the rotational forces generated by the crankshaft. By balancing these forces, it reduces vibrations and ensures that the crankshaft operates within its designed parameters.

Relationship with the Piston and Connecting Rod Assembly

As the pistons move up and down within the cylinders, they create forces that can lead to engine vibrations. The Engine Balancer mitigates these forces, allowing the piston and connecting rod assembly to function more efficiently and with reduced wear.

Impact on the Cylinder Block and Main Bearings

Excessive vibrations can lead to increased stress on the cylinder block and main bearings. The Engine Balancer helps in minimizing these vibrations, thereby protecting these components from premature wear and potential failure.

Contribution to the Harmonic Balancer

In engines equipped with a harmonic balancer, the Engine Balancer works in tandem to further reduce torsional vibrations. This collaboration ensures that the harmonic balancer can perform its function more effectively, leading to a more stable and reliable engine operation.

Effect on the Timing Chain or Belt

The Engine Balancer also plays a role in maintaining the integrity of the timing chain or belt. By reducing vibrations, it helps in keeping the timing components aligned and functioning smoothly, which is vital for the engine’s overall performance.

Influence on the Flywheel or Flexplate

In both gasoline and diesel engines, the flywheel or flexplate is subject to significant forces. The Engine Balancer assists in managing these forces, ensuring that the flywheel or flexplate operates within its designed tolerances, thus contributing to a more consistent engine performance.

Role in the Valve Train

Although indirectly, the Engine Balancer influences the valve train by ensuring that the engine runs smoothly. Reduced vibrations mean that the camshaft, lifters, and valves experience less stress, leading to improved valve operation and longevity.

Impact on the Engine Mounts

Engine mounts are designed to absorb vibrations and secure the engine to the chassis. The Engine Balancer reduces the amount of vibration transmitted to the mounts, prolonging their lifespan and maintaining the structural integrity of the engine compartment.

Conclusion

The Cummins 4944353 Engine Balancer is a vital component that enhances the performance and durability of various engine systems by effectively managing and reducing vibrations. Its role in maintaining engine stability, reducing wear on components, and ensuring smooth operation makes it an essential part of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.