This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

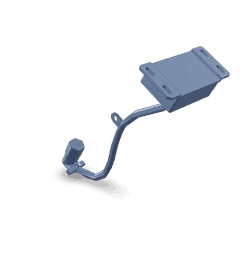

The Engine Control Interface Module (Part #4951963) by Cummins is a sophisticated component designed to enhance the operation of commercial trucks. This module serves as a central hub for engine management, facilitating communication between various engine systems and ensuring optimal performance. Its significance lies in its ability to monitor and adjust engine parameters in real-time, contributing to efficient and reliable truck operation 1.

Function and Operation

The Engine Control Interface Module operates within the truck’s engine management system by continuously monitoring and controlling various engine parameters. It collects data from sensors throughout the engine and uses this information to make adjustments to fuel injection, ignition timing, and other critical functions. This real-time data processing allows the module to maintain engine performance under varying conditions, ensuring smooth and efficient operation 2.

Key Features

The primary features of the Engine Control Interface Module include robust connectivity options, advanced diagnostic capabilities, and seamless integration with other engine components. It supports multiple communication protocols, allowing it to interface with a wide range of sensors and control units. The module’s diagnostic functions enable it to identify and report issues, facilitating timely maintenance and reducing downtime. Additionally, its integration with other engine components ensures cohesive operation and enhances overall engine performance 3.

Benefits

The Engine Control Interface Module offers several advantages, including improved engine performance, enhanced fuel efficiency, and simplified maintenance procedures. By precisely controlling engine parameters, it helps achieve optimal performance and reliability. The module’s ability to monitor and adjust fuel injection and ignition timing contributes to better fuel efficiency, reducing operating costs. Furthermore, its diagnostic capabilities streamline maintenance processes, allowing for quicker issue identification and resolution 4.

Troubleshooting and Maintenance

Common issues with the Engine Control Interface Module may include communication errors, sensor malfunctions, and software glitches. Troubleshooting steps involve checking connections, verifying sensor readings, and updating the module’s software as needed. Routine maintenance includes regular diagnostic checks, ensuring all connections are secure, and keeping the module’s software up to date. These practices help maintain optimal performance and extend the module’s longevity 5.

Integration with Cummins Engines

The Engine Control Interface Module integrates seamlessly with Cummins engines, offering compatibility with various engine models. It plays a significant role in Cummins’ overall engine management strategy by providing precise control and monitoring of engine functions. This integration ensures that Cummins engines operate efficiently and reliably, meeting the high standards expected in commercial trucking applications 6.

Technological Advancements

The Engine Control Interface Module incorporates several technological innovations, such as advanced sensors, real-time data processing, and wireless communication capabilities. These advancements allow the module to provide more accurate and timely control of engine parameters. The use of wireless communication enables remote monitoring and diagnostics, further enhancing the module’s functionality and convenience 7.

Environmental Impact

The use of the Engine Control Interface Module contributes to reduced emissions and improved fuel efficiency. By optimizing engine performance and fuel consumption, it helps lower the environmental impact of commercial trucks. The module’s precise control of engine parameters ensures that emissions are kept within regulatory limits, promoting cleaner and more sustainable operation 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and excellence in the automotive industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial and industrial applications. Cummins’ dedication to advancing technology and improving efficiency underscores its position as a leader in the industry 9.

Cummins Engine Control Interface Module 4951963

The Cummins Engine Control Interface Module, part number 4951963, is a critical component designed to integrate seamlessly with various Cummins engine models. This module plays a pivotal role in ensuring the smooth operation and optimal performance of the engines by facilitating communication between the engine control unit and other vehicle systems.

Integration with Cummins Engines

QSK50 and CM2150 Engines

The QSK50 and CM2150 engines are part of Cummins’ heavy-duty diesel engine lineup, known for their robust performance and reliability in demanding applications. The Engine Control Interface Module 4951963 is engineered to interface with these engines, ensuring precise control and monitoring of engine functions. This integration is crucial for maintaining engine efficiency, reducing emissions, and enhancing overall vehicle performance 10.

MCRS Engines

The MCRS (Modular Component Remanufacturing System) engines represent another segment of Cummins’ versatile engine portfolio. These engines are designed for remanufacturing, which extends their lifecycle and reduces environmental impact. The Cummins Engine Control Interface Module 4951963 is compatible with MCRS engines, providing a seamless connection that supports advanced diagnostics and control features. This compatibility ensures that the remanufactured engines perform at peak levels, meeting the stringent requirements of modern transportation and industrial applications 11.

Compatibility and Functionality

The Engine Control Interface Module 4951963 is designed to be a versatile component, ensuring compatibility across different engine models within the Cummins lineup. Its primary function is to act as a bridge between the engine control unit and other vehicle systems, facilitating real-time data exchange and control signals. This integration is essential for:

- Optimizing Engine Performance: By providing accurate and timely data, the module helps in fine-tuning engine operations, ensuring optimal fuel efficiency and power output.

- Emissions Control: The module supports advanced emission control strategies, helping the engines comply with regulatory standards.

- Diagnostics and Troubleshooting: It enables comprehensive diagnostics, allowing for quick identification and resolution of potential issues, thereby minimizing downtime 12.

The Cummins Engine Control Interface Module 4951963 is a testament to the company’s commitment to innovation and quality, providing a reliable and efficient solution for integrating and controlling modern diesel engines.

Role of Part 4951963 Engine Control Interface Module in Engine Systems

The Part 4951963 Engine Control Interface Module (ECIM) is integral to the seamless operation of various engine systems by facilitating communication and data exchange between the Engine Control Module (ECM) and other electronic components.

Integration with the Harness

The ECIM interfaces directly with the vehicle’s wiring harness, which serves as the central nervous system for the engine’s electrical components. This connection allows the ECIM to transmit and receive signals from sensors and actuators distributed throughout the engine system. The harness carries data related to engine performance, such as temperature, pressure, and fuel levels, enabling the ECIM to monitor and adjust engine operations in real-time.

Interaction with Electronic Control Module Wiring

The ECIM also plays a significant role in the electronic control module (ECM) wiring. It acts as a mediator, ensuring that the ECM receives accurate and timely data from various sensors. This data is essential for the ECM to make precise adjustments to fuel injection, ignition timing, and other critical parameters. The ECIM enhances the reliability of the ECM wiring by filtering out noise and ensuring signal integrity, which is vital for the ECM to function correctly.

In summary, the Part 4951963 Engine Control Interface Module is a key component that enhances the efficiency and performance of engine systems by ensuring smooth and accurate communication between the ECM and other electronic components via the harness and ECM wiring.

Conclusion

The Engine Control Interface Module (Part #4951963) by Cummins is a vital component in the engine management system of commercial trucks. Its role in monitoring and adjusting engine parameters in real-time ensures optimal performance, enhanced fuel efficiency, and reduced environmental impact. The module’s advanced features, such as robust connectivity, diagnostic capabilities, and seamless integration with other engine components, make it an essential part of Cummins’ engine management strategy. By facilitating precise control and monitoring of engine functions, the Engine Control Interface Module contributes to the reliable and efficient operation of Cummins engines, meeting the high standards expected in commercial trucking applications.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5579821.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.