This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

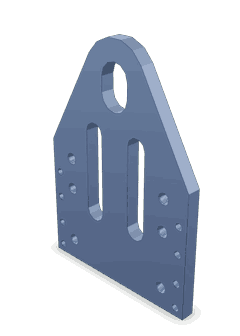

The Cummins 4975748 Engine Lifting Bracket is a specialized component designed for use in commercial trucks. Its primary role is to facilitate the safe and efficient removal and installation of engines. This bracket is integral to maintenance procedures, ensuring that operations are conducted with precision and care.

Purpose and Function

The Cummins 4975748 Engine Lifting Bracket serves a vital function in the engine maintenance process. It is engineered to provide a secure attachment point for lifting equipment, allowing for the safe handling of heavy engine components. By offering a stable and reliable connection, this bracket enhances the efficiency and safety of engine removal and installation tasks. Its design ensures that the engine can be maneuvered with minimal risk of damage to the engine or surrounding components 1.

Key Features

The Cummins 4975748 Engine Lifting Bracket is characterized by several key features that contribute to its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The bracket’s design includes precise attachment points and robust construction, which provide stability during lifting operations. Additionally, its compatibility with various Cummins engine models makes it a versatile component for fleet maintenance 2.

Benefits

Utilizing the Cummins 4975748 Engine Lifting Bracket offers several advantages. It simplifies the engine maintenance process by providing a secure and stable platform for lifting, which can reduce the time required for engine removal and installation. This efficiency can lead to cost savings for fleet operators. Moreover, the bracket enhances safety by minimizing the risk of accidents during lifting operations, protecting both the equipment and the personnel involved 3.

Installation and Usage

Proper installation and usage of the Cummins 4975748 Engine Lifting Bracket are critical to its effectiveness. It should be installed according to the manufacturer’s guidelines to ensure a secure fit. When in use, it is important to follow best practices for lifting, including using appropriate rigging techniques and adhering to load limits. Regular inspections before use can help identify any potential issues and ensure the bracket remains in optimal condition.

Troubleshooting and Maintenance

To maintain the Cummins 4975748 Engine Lifting Bracket in good working condition, regular inspections and maintenance are recommended. Common issues may include wear and tear or damage from use. Addressing these issues promptly can prolong the lifespan of the bracket and ensure reliable performance. Maintenance should include cleaning the bracket and checking for any signs of damage or corrosion.

Safety Considerations

When using the Cummins 4975748 Engine Lifting Bracket, several safety considerations should be kept in mind. Proper rigging techniques are essential to ensure the bracket is securely attached and can support the intended load. Operators should be trained in the correct use of the bracket and lifting equipment. Adhering to load limits and conducting regular safety checks can help prevent accidents and ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck and engine industry. The company is committed to providing reliable and efficient solutions that meet the needs of its customers, demonstrating a dedication to excellence and customer satisfaction.

Compatibility with Cummins Engines

The Engine Lifting Bracket part number 4975748, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This bracket is an essential component for safely lifting and securing the engine during maintenance and repair operations.

QST30 Engines

The Cummins QST30 engines, including the QST30 CM2350 T101 and QST30 CM552, are engineered for heavy-duty applications, and the 4975748 Engine Lifting Bracket is specifically tailored to fit these models. This bracket ensures that the engine can be lifted with precision and stability, reducing the risk of damage during the lifting process.

Compatibility and Installation

When installing the Engine Lifting Bracket 4975748 on Cummins QST30 engines, it is crucial to follow the manufacturer’s guidelines to ensure a secure fit. The bracket is designed to attach to specific points on the engine, providing a robust connection that can support the engine’s weight. Proper installation is vital for the safety of personnel and the integrity of the engine.

Importance of the Bracket

The Engine Lifting Bracket 4975748 plays a critical role in the maintenance and repair of Cummins QST30 engines. By providing a reliable means to lift the engine, it helps prevent accidents and ensures that the engine can be handled with ease. This bracket is a testament to Cummins’ commitment to quality and safety in engine maintenance.

Role of Part 4975748 Engine Lifting Bracket in Engine Systems

The 4975748 Engine Lifting Bracket is an essential component in the assembly and maintenance of various engine systems. Its primary function is to provide a secure and stable mounting point for the engine, facilitating easier handling and installation processes.

Integration with Engine Components

When integrating the 4975748 Engine Lifting Bracket with an engine system, it is typically attached to the engine block. This bracket serves as a pivotal point for lifting the engine, reducing the risk of damage during removal or installation.

Interaction with Drive and Fan Systems

In systems where the engine is connected to a drive mechanism, the lifting bracket ensures that the engine remains aligned properly during the lifting process. This is particularly important for engines connected to fan systems, where precise alignment is necessary to maintain efficient airflow and cooling.

Role in Package and Product Installation

During the installation of engine packages, the 4975748 Engine Lifting Bracket plays a significant role. It allows for the engine to be positioned accurately within the package, ensuring that all connections to ancillary components are made correctly. This is vital for the overall functionality and performance of the engine system.

Importance in Spare Mounting

For spare engines or during routine maintenance, the lifting bracket provides a reliable method for securely mounting the engine. This is especially useful in environments where space is limited, and precise engine placement is required to avoid interference with other components.

Facilitation of Product Installation

When installing new engine products, the 4975748 Engine Lifting Bracket simplifies the process by offering a stable platform for the engine. This ensures that the engine can be installed with minimal risk of misalignment or damage, contributing to a smoother installation experience.

Enhanced Safety and Efficiency

By providing a robust mounting solution, the 4975748 Engine Lifting Bracket enhances both safety and efficiency in engine handling. It allows mechanics and engineers to work with greater confidence, knowing that the engine is securely supported throughout the installation or maintenance process.

Conclusion

The Cummins 4975748 Engine Lifting Bracket is a critical component in the maintenance and installation of Cummins engines. Its robust design, compatibility with various engine models, and emphasis on safety and efficiency make it an indispensable tool for fleet operators and maintenance professionals. Proper installation, regular maintenance, and adherence to safety guidelines ensure that this Cummins part continues to provide reliable performance and contribute to the overall efficiency of engine maintenance operations.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Electrical Systems and Mechatronics, Second Edition, Michael Hilgers, Springer Vieweg, 2023.

↩ -

Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, Wilfried J Bartz, CRC Press, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.