This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4995212 Cable Connector is a specialized component designed for use in commercial trucks. It plays a role in the electrical system by ensuring the reliable transfer of power and data between various components. This connector is integral to maintaining the operational efficiency and safety of the vehicle.

Basic Concepts of Cable Connectors

Cable connectors are devices used to join electrical circuits. They facilitate the transfer of power and data by providing a secure and reliable connection between cables and electrical components. In the context of commercial trucks, these connectors are vital for ensuring that all electrical systems function correctly and efficiently 1.

Purpose of the 4995212 Cable Connector

The 4995212 Cable Connector is specifically designed to connect various electrical components within the truck’s system. Its role includes ensuring a stable and consistent electrical connection, which is important for the performance of the truck’s electrical systems. This connector helps in maintaining the integrity of the electrical signals and power distribution throughout the vehicle.

Key Features

The 4995212 Cable Connector boasts several key features that enhance its performance and durability. These include a robust design that can withstand the harsh conditions often encountered in commercial trucking. The materials used in its construction are chosen for their durability and resistance to corrosion. Additionally, the connector features a secure connection type that ensures a reliable electrical link between components.

Benefits

The benefits of using the 4995212 Cable Connector include improved electrical conductivity, which ensures efficient power transfer. Its enhanced durability means it can withstand the rigors of commercial use, reducing the need for frequent replacements. The connector is also resistant to environmental factors such as moisture and extreme temperatures, further ensuring its reliability. Additionally, it is designed for ease of installation, allowing for quick and straightforward setup.

Installation Process

Installing the 4995212 Cable Connector involves several steps to ensure optimal performance. Begin by gathering the necessary tools, which may include a wire stripper, crimping tool, and a multimeter for testing. Prepare the cables by stripping the insulation and ensuring they are clean and free of corrosion. Next, insert the prepared cables into the connector and secure them using the appropriate crimping technique. Finally, test the connection to confirm that it is secure and functioning correctly.

Troubleshooting Common Issues

Common issues with the 4995212 Cable Connector may include poor connections, corrosion, or physical damage. To troubleshoot these problems, first, inspect the connector for any visible signs of damage or corrosion. Use a multimeter to test the electrical continuity and identify any breaks in the connection. If corrosion is present, clean the connector thoroughly before retesting. For physical damage, replacement of the connector may be necessary.

Maintenance Tips

To ensure the long-term reliability of the 4995212 Cable Connector, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the connector to remove any corrosion, and replacing any worn-out components. Regular maintenance helps in preventing unexpected failures and ensures the continued efficient operation of the truck’s electrical system.

Safety Considerations

When working with the 4995212 Cable Connector, it is important to follow safety guidelines to prevent electrical hazards. Ensure that the truck’s electrical system is de-energized before beginning any work on the connector. Use appropriate personal protective equipment, such as insulated gloves and safety glasses. Additionally, follow proper handling procedures to avoid damage to the connector or injury to yourself.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. The company’s product range includes a variety of engine and component solutions designed to meet the demanding needs of commercial trucking 2.

Compatibility with Cummins Engines

The Cummins Cable Connector part number 4995212 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connections and optimal performance. This part is compatible with the following engines:

K38 and K50 Engines

The K38 and K50 engines are part of Cummins’ robust lineup, known for their durability and efficiency. The 4995212 Cable Connector fits these engines by providing a secure and stable connection for various electrical components, ensuring that the engine’s electrical systems operate without interruption.

QSK50 CM2150 Engines

The QSK50 CM2150 engines are high-performance models that require precise and reliable electrical connections. The 4995212 Cable Connector is engineered to meet these demands, offering a perfect fit that enhances the engine’s electrical integrity and performance.

QSK50 CM2150 MCRS Engines

The QSK50 CM2150 MCRS engines are equipped with advanced features that necessitate specialized components. The 4995212 Cable Connector is designed to integrate with these engines, ensuring that all electrical connections are secure and reliable, supporting the engine’s advanced functionalities.

By using the 4995212 Cable Connector, technicians and operators can ensure that their Cummins engines maintain optimal performance and reliability, with secure and efficient electrical connections.

Role of the 4995212 Cable Connector in Engine Systems

The 4995212 Cable Connector is an important component in the arrangement of various engine systems, facilitating seamless operation and communication between different parts.

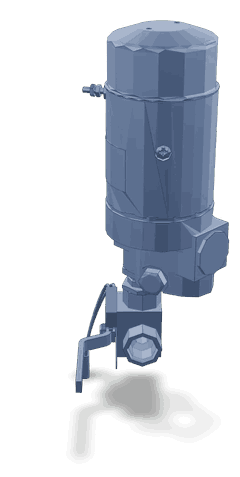

In the context of the Engine Lubrication Primer, the 4995212 Cable Connector ensures that the electrical signals required for the primer’s operation are transmitted accurately. This connector links the primer to the control system, allowing for precise activation and deactivation based on engine requirements.

When integrated with the Lubricating Oil Priming Pump Mount, the 4995212 Cable Connector plays a significant role in maintaining the electrical integrity of the system. It ensures that the pump receives the necessary signals to initiate oil flow, which is vital for reducing friction and wear within the engine components 3.

The Primer system also benefits from the 4995212 Cable Connector by ensuring that the electrical connections are secure and reliable. This is particularly important during the engine start-up phase, where the primer needs to deliver a consistent supply of lubricant to critical engine parts.

Lastly, in the Engine Lubricating System, the 4995212 Cable Connector aids in the coordination between various sensors and the control unit. It helps in monitoring oil pressure and temperature, allowing the system to make real-time adjustments to maintain optimal lubrication conditions.

Overall, the 4995212 Cable Connector is a fundamental element that enhances the efficiency and reliability of engine lubrication systems by ensuring robust and consistent electrical connections.

Conclusion

The Cummins 4995212 Cable Connector is a critical component in the electrical systems of commercial trucks, ensuring reliable power and data transfer. Its robust design, durability, and ease of installation make it a valuable part for maintaining the operational efficiency and safety of vehicles. Regular maintenance and proper installation are key to maximizing its benefits and ensuring long-term reliability.

-

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.