This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

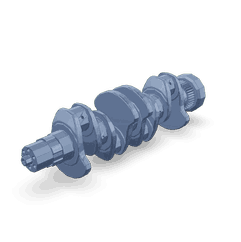

The Cummins 5261376 Engine Crankshaft is a vital component in the operation of commercial trucks. It is designed to convert the reciprocating motion of the pistons into rotational motion, which is necessary for driving the vehicle. This crankshaft is integral to the engine’s performance, ensuring efficient and reliable operation of the truck.

Basic Concepts of Engine Crankshafts

An engine crankshaft is a mechanical part that plays a fundamental role in an internal combustion engine. Its primary function is to convert the linear motion of the pistons into rotational motion. This conversion is achieved through a series of crankpins and connecting rods, which are strategically positioned along the crankshaft. As the pistons move up and down, the connecting rods transfer this motion to the crankshaft, causing it to rotate. This rotational motion is then transmitted to the transmission system, ultimately driving the vehicle 1.

Purpose of the Cummins 5261376 Engine Crankshaft

The Cummins 5261376 Engine Crankshaft serves a specific role in the operation of a truck. It is responsible for converting the reciprocating motion of the pistons into rotational motion. This conversion is crucial for the engine’s operation, as it allows the engine to generate the power needed to drive the vehicle. The crankshaft’s design and construction ensure that it can withstand the high stresses and loads associated with commercial truck operation, providing reliable and efficient performance 2.

Key Features

The Cummins 5261376 Engine Crankshaft is characterized by several key features that enhance its performance and durability. These include its robust design, which is engineered to withstand the high stresses and loads of commercial truck operation. The crankshaft is constructed from high-quality materials, such as forged steel, which provide excellent strength and durability. Additionally, the crankshaft features precision-machined journals and crankpins, ensuring smooth and efficient operation. These features contribute to the crankshaft’s overall performance and longevity 3.

Benefits

The Cummins 5261376 Engine Crankshaft offers several benefits that contribute to improved engine efficiency, reliability, and longevity. Its robust design and high-quality materials ensure that it can withstand the demanding conditions of commercial truck operation. The precision-machined journals and crankpins reduce friction and wear, enhancing the crankshaft’s efficiency and durability. Additionally, the crankshaft’s design allows for better balance and reduced vibrations, contributing to a smoother and more reliable engine operation 4.

Troubleshooting and Maintenance

To ensure the Cummins 5261376 Engine Crankshaft operates efficiently and prolong its lifespan, regular maintenance and troubleshooting are necessary. Common issues related to the crankshaft include vibrations, noise, or performance decline. These issues can often be traced to problems with the crankshaft’s bearings, journals, or connecting rods. Regular inspections and maintenance, such as checking for wear and tear, ensuring proper lubrication, and addressing any issues promptly, can help prevent these problems and ensure the crankshaft operates smoothly.

Manufacturing and Quality Control

Cummins employs rigorous manufacturing processes and quality control measures to ensure the reliability and performance of the 5261376 Engine Crankshaft. The crankshaft is forged from high-quality steel, ensuring excellent strength and durability. Precision machining processes are used to create the crankshaft’s journals and crankpins, ensuring smooth and efficient operation. Additionally, Cummins implements stringent quality control measures throughout the manufacturing process, including inspections and testing, to ensure that each crankshaft meets the highest standards of quality and performance.

Integration with Other Engine Components

The Cummins 5261376 Engine Crankshaft interacts with other engine components, such as pistons, connecting rods, and the flywheel, to ensure smooth and efficient engine operation. The crankshaft’s crankpins are connected to the pistons via connecting rods, allowing the reciprocating motion of the pistons to be converted into rotational motion. This rotational motion is then transmitted to the flywheel, which stores and releases energy to maintain a consistent engine speed. The crankshaft’s design and construction ensure that it can withstand the high stresses and loads associated with these interactions, providing reliable and efficient engine operation.

Historical Development

The development of engine crankshafts has evolved over time, with advancements in materials, design, and manufacturing techniques leading to the current iteration of the Cummins 5261376 Engine Crankshaft. Early crankshafts were often made from cast iron or bronze, which provided limited strength and durability. Advances in materials, such as the use of forged steel, have significantly improved the strength and durability of crankshafts. Additionally, improvements in design and manufacturing techniques, such as precision machining and computer-aided design, have enhanced the efficiency and reliability of crankshafts.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, designed to meet the demanding needs of commercial truck operators. Cummins is known for its commitment to quality, reliability, and customer satisfaction, making it a trusted name in the industry.

Cummins Engine Crankshaft 5261376 Compatibility

The Cummins Engine Crankshaft part number 5261376 is designed to fit a variety of Cummins engines. Here is a detailed look at the compatibility of this crankshaft with the listed engines:

F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- QSF3.8 CM2350 F107

The Cummins Engine Crankshaft 5261376 is compatible with the F3.8 series engines, specifically those with the CM2350 and CM2620 configurations. This crankshaft ensures smooth engine operation by converting the reciprocating motion of the pistons into rotational motion.

ISF3.8 Series

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

The ISF3.8 series engines, including the CM2220 and CM2350 configurations, also utilize the Cummins Engine Crankshaft 5261376. This crankshaft is engineered to handle the specific demands of these engines, providing durability and reliability.

QSF3.8 Series

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

The QSF3.8 series engines, particularly those with the CM2350 and CM2880 configurations, are compatible with the Cummins Engine Crankshaft 5261376. This crankshaft is designed to work seamlessly with these engines, ensuring optimal performance and longevity.

Summary

The Cummins Engine Crankshaft 5261376 is a versatile component that fits a range of Cummins engines across different series. Its compatibility with the F3.8, ISF3.8, and QSF3.8 series highlights its adaptability and importance in maintaining engine functionality.

Role of Part 5261376 Engine Crankshaft in Engine Systems

The part 5261376 Engine Crankshaft is integral to the operation of the engine, facilitating the transformation of linear motion into rotational motion. This conversion is essential for the engine’s functionality, as it drives various components to ensure smooth and efficient operation.

Interaction with the Engine Block

The Engine Crankshaft is housed within the engine block, where it is supported by main bearings. These bearings allow the crankshaft to rotate with minimal friction. As the crankshaft rotates, it interacts with the pistons via connecting rods, transferring the force generated during the combustion process into rotational motion. This motion is then transmitted through the flywheel, ultimately driving the vehicle’s transmission system.

Coordination with Cylinders

Each cylinder in the engine is connected to the crankshaft via a piston and a connecting rod. When fuel combusts in a cylinder, it pushes the piston downward. This linear motion is converted into rotational motion by the crankshaft, which rotates as the piston moves. The crankshaft’s design, with its crankpins and counterweights, ensures that the rotational force is balanced, reducing vibrations and enhancing the engine’s stability and performance.

In summary, the part 5261376 Engine Crankshaft plays a significant role in the engine’s operation by converting the linear motion of the pistons into rotational motion, which is essential for driving the vehicle. Its precise interaction with the engine block and cylinders ensures efficient and smooth engine performance.

Conclusion

The Cummins 5261376 Engine Crankshaft is a critical component in the operation of commercial trucks, ensuring efficient and reliable engine performance. Its robust design, high-quality materials, and precision-machined features contribute to its durability and efficiency. Regular maintenance and troubleshooting are essential to prolong its lifespan and ensure optimal performance. Cummins’ rigorous manufacturing processes and quality control measures guarantee the reliability and performance of this crankshaft, making it a trusted component in the commercial truck industry.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.