This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

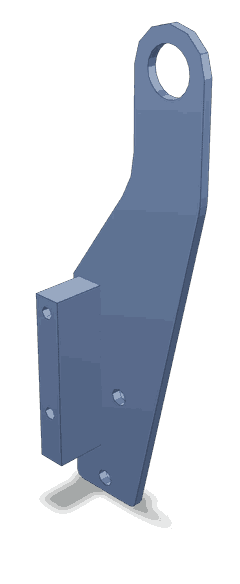

The 5302879 Engine Lifting Bracket, manufactured by Cummins, is a specialized component designed for the maintenance and repair of heavy-duty trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this bracket to facilitate efficient and safe engine handling during maintenance procedures.

Purpose and Function

The primary role of the 5302879 Engine Lifting Bracket is to aid in the removal and installation of engines in heavy-duty trucks. It enhances the efficiency and safety of engine maintenance operations by providing a secure point for lifting and supporting the engine during these processes 1.

Key Features

This Cummins part is engineered with specific design and construction features to ensure optimal performance. It is made from high-strength materials, offering a robust load-bearing capacity. The bracket’s design includes unique elements that enhance its functionality, such as precision-machined surfaces for a secure fit and corrosion-resistant coatings to ensure longevity in various operating environments 2.

Benefits

Using the 5302879 Engine Lifting Bracket offers several advantages. It improves safety during engine handling by providing a stable and secure lifting point. Additionally, it reduces maintenance time due to its efficient design, allowing for quicker engine removal and installation. The bracket’s durable construction ensures it can withstand repeated use, offering a reliable solution for heavy-duty truck maintenance 3.

Installation and Usage

Proper installation and usage of the Engine Lifting Bracket are crucial for effective and secure engine lifting operations. The installation process involves securing the bracket to the engine and the truck frame according to the manufacturer’s guidelines. It is important to follow safety precautions, such as ensuring all connections are tight and the lifting equipment is rated for the engine’s weight. Best practices include regular inspections of the bracket for signs of wear or damage before use.

Troubleshooting and Maintenance

Common issues with the Engine Lifting Bracket may include wear and tear from repeated use or corrosion in harsh environments. Troubleshooting steps involve inspecting the bracket for damage, ensuring all connections are secure, and replacing any worn or damaged components. Maintenance tips to prolong the lifespan of the bracket include regular cleaning, applying protective coatings, and storing it in a dry environment when not in use.

Compatibility and Applications

The 5302879 Engine Lifting Bracket is designed for use with specific types of engines and truck models. Its applicability extends to various commercial and industrial settings where heavy-duty trucks are maintained and repaired. Understanding the compatibility of the bracket with different engine types and truck models is important for ensuring effective use.

Safety Considerations

When using the Engine Lifting Bracket, it is important to adhere to safety protocols and guidelines. This includes conducting regular inspections of the bracket for any signs of damage or wear, ensuring all lifting equipment is in good condition and rated for the intended load, and following the manufacturer’s recommendations for use. Safety is paramount in engine maintenance operations, and the Engine Lifting Bracket is designed with these considerations in mind.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the 5302879 Engine Lifting Bracket, which is designed to meet the demanding requirements of heavy-duty truck maintenance and repair.

Cummins Engine Lifting Bracket 5302879 Compatibility

The Cummins Engine Lifting Bracket, part number 5302879, is designed to facilitate the safe and efficient lifting of specific Cummins engines. This part is engineered to ensure that the engine can be securely lifted without causing damage to the engine or the lifting mechanism.

QSB3.3 CM2250 EC

The QSB3.3 CM2250 EC engine is one of the models where the 5302879 lifting bracket is applicable. This engine is known for its robust design and reliability, making it a popular choice in various industrial applications. The lifting bracket is specifically designed to fit the unique mounting points of the QSB3.3 CM2250 EC, ensuring a secure fit and ease of use during maintenance or installation procedures.

Grouping of Engines

The Cummins Engine Lifting Bracket 5302879 is compatible with a range of engines that share similar design characteristics and mounting points. This includes, but is not limited to, the QSB3.3 CM2250 EC. The bracket’s design allows it to be used across multiple engine models, providing a versatile solution for engine lifting needs.

By ensuring compatibility with a group of engines, the 5302879 lifting bracket offers a cost-effective and practical solution for maintenance and installation tasks, reducing the need for multiple specialized parts.

Role of Part 5302879 Engine Lifting Bracket in Engine Systems

The part 5302879 Engine Lifting Bracket is an essential component in the arrangement and lifting processes of various engine systems. It facilitates secure attachment points for lifting equipment, ensuring that the engine can be safely and efficiently moved during maintenance, repair, or installation procedures.

Integration with Engine Components

-

Engine Block Attachment: The Engine Lifting Bracket is typically bolted to the engine block. This secure attachment provides a stable and reliable point for lifting, reducing the risk of engine damage during the lifting process.

-

Crankshaft Alignment: When aligning the crankshaft during engine installation, the Lifting Bracket helps maintain the engine in the correct position. This ensures precise alignment with the transmission or other connected components, which is vital for the engine’s operational integrity.

-

Support During Removal: During engine removal, the Lifting Bracket supports the engine’s weight, allowing mechanics to disconnect ancillary components such as the exhaust system, fuel lines, and electrical connections with greater ease and safety.

-

Stabilization for Ancillary Component Access: The bracket stabilizes the engine, providing a steady platform for accessing and working on ancillary components like the alternator, starter motor, and various sensor units. This stabilization is particularly important in confined engine bays where space is limited.

-

Facilitation of Engine Rotation: In scenarios where the engine needs to be rotated for access to underside components, the Lifting Bracket allows controlled and safe rotation, minimizing the risk of injury or component damage.

-

Enhanced Safety during Maintenance: By providing a robust lifting point, the Engine Lifting Bracket enhances overall safety during maintenance operations. It allows mechanics to use appropriate lifting gear, such as hoists or cranes, ensuring that the engine is lifted smoothly and securely.

Conclusion

In summary, the 5302879 Engine Lifting Bracket plays a significant role in the safe and efficient handling of engine systems, contributing to the integrity and safety of engine maintenance and installation processes. Its robust design, compatibility with various engine models, and integration with engine components make it a valuable tool for mechanics and technicians in the heavy-duty truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.