This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

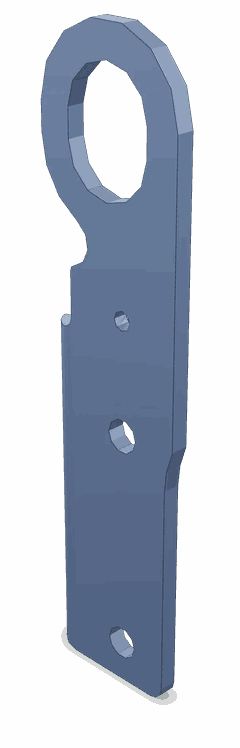

The Cummins 5340121 Engine Lifting Bracket is a specialized component designed for the maintenance and repair of heavy-duty trucks. This bracket facilitates the safe and efficient removal and installation of engines, which is a significant aspect of truck maintenance. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, ensuring that engine servicing is conducted with precision and safety.

Purpose and Function

This Cummins part is engineered to support the engine during removal and installation processes. It provides a secure attachment point for lifting equipment, allowing for the engine to be handled with stability and control. This bracket simplifies the complex task of engine servicing by offering a reliable means to lift and position the engine, thereby enhancing the efficiency and safety of the maintenance procedure.

Key Features

The design and construction of the 5340121 are characterized by several key features. It is made from high-quality materials that offer durability and resistance to the stresses encountered during engine lifting. The bracket’s structural integrity is ensured through precise engineering, which includes robust welds and a design that distributes load evenly. Unique design elements, such as ergonomic attachment points and compatibility with various lifting equipment, further enhance its functionality.

Benefits

Utilizing the 5340121 offers several advantages. It contributes to improved safety during engine handling by providing a stable and secure lifting point. This reduces the risk of accidents associated with engine servicing. Additionally, the bracket can help reduce maintenance time by streamlining the engine removal and installation processes. Its design also enhances overall engine accessibility, making it easier for technicians to perform necessary repairs and inspections.

Installation Process

Installing the 5340121 involves several steps to ensure proper functionality and safety. The process begins with gathering the necessary tools and ensuring the truck is securely supported. Preparatory steps include cleaning the installation area and verifying that all components are in good condition. Alignment considerations are critical during installation to ensure the bracket is correctly positioned for optimal performance. Detailed instructions should be followed to secure the bracket firmly in place.

Troubleshooting and Maintenance

Common issues with the 5340121 may include wear and tear or misalignment. Troubleshooting steps involve inspecting the bracket for any signs of damage or deformation and ensuring all attachment points are secure. Regular maintenance, such as cleaning and checking for corrosion, is recommended to ensure the longevity and optimal performance of the bracket. Following manufacturer guidelines for maintenance can help prevent issues and ensure safe operation.

Safety Considerations

When using the 5340121, it is important to observe several safety practices. Understanding the load limits of the bracket and ensuring it is not exceeded is crucial for safe operation. Proper lifting techniques, including the use of appropriate lifting equipment and personnel training, are necessary to prevent accidents. Regular inspections of the bracket for any signs of wear or damage should be conducted to maintain its integrity and safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the automotive industry, particularly in the production of diesel engines and related components. The company’s commitment to excellence and customer satisfaction has made it a trusted name among professionals in the heavy-duty truck and engine servicing sectors 1.

Compatibility

The Engine Lifting Bracket part number 5340121 is designed to fit a variety of Cummins engines, ensuring secure and reliable lifting during maintenance and installation processes. Here’s a detailed overview of its compatibility with different engine models:

B4.5 Series Engines

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

- QSF3.8 CM2350 F107

The 5340121 bracket is engineered to fit seamlessly with the B4.5 series engines, providing robust support for lifting operations. These engines are known for their durability and efficiency, making the bracket an essential component for maintenance.

D4.0 Series Engines

- D4.0 CM2620 D103B

The bracket is compatible with the D4.0 CM2620 D103B engine, ensuring that the lifting process is handled with precision and ease. This engine is designed for heavy-duty applications, and the bracket’s design complements its structural integrity.

F3.8 Series Engines

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

The 5340121 bracket is versatile enough to fit various F3.8 series engines, including the CM2350, CM2620, and CM2880 models. This compatibility ensures that the bracket can be used across different engine configurations, providing a standardized solution for lifting these engines.

F4.5 Series Engines

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- ISF4.5 CM2220 F123

For the F4.5 series engines, the 5340121 bracket offers reliable lifting support. These engines are designed for high performance and efficiency, and the bracket’s design ensures that the lifting process does not compromise the engine’s structural integrity.

F3.8 Series Engines (Additional)

- F3.8 F102

The bracket is also compatible with the F3.8 F102 engine, providing a reliable solution for lifting this specific model. This compatibility extends the bracket’s utility across a broader range of engine types.

By ensuring compatibility with a wide range of Cummins engines, the 5340121 Engine Lifting Bracket provides a reliable and efficient solution for maintenance and installation processes.

Role of Part 5340121 Engine Lifting Bracket in Engine Systems

The 5340121 Engine Lifting Bracket is a critical component in the arrangement and lifting of engine systems. Its primary function is to provide a secure attachment point for lifting equipment, ensuring that the engine can be safely and efficiently moved during maintenance, repair, or installation procedures.

When integrating the 5340121 Engine Lifting Bracket with an engine system, it is positioned at strategic points on the engine block. This placement allows lifting equipment, such as cranes or hoists, to securely grip the bracket, distributing the engine’s weight evenly to prevent damage during the lifting process.

In addition to its lifting capabilities, the 5340121 Engine Lifting Bracket also plays a role in the overall arrangement of the engine within its compartment. By providing a stable and reliable mounting point, it ensures that the engine remains properly aligned with other components, such as the transmission, exhaust system, and ancillary devices. This alignment is vital for the engine’s optimal performance and longevity.

Furthermore, the bracket’s design considers the engine’s center of gravity, enhancing the stability of the lifting operation. This feature is particularly important when dealing with high-performance or heavy-duty engines, where precise handling is required to avoid accidents or component misalignment.

In summary, the 5340121 Engine Lifting Bracket is a fundamental element in the safe and effective management of engine systems, facilitating both the lifting and proper arrangement of the engine within its operational environment.

Conclusion

The Cummins 5340121 Engine Lifting Bracket is an indispensable tool for the maintenance and repair of heavy-duty trucks. Its robust design, compatibility with a wide range of Cummins engines, and the safety it provides during engine handling make it a valuable asset for any technician. By understanding its features, benefits, and proper use, professionals can ensure efficient and safe engine servicing.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.