5375518

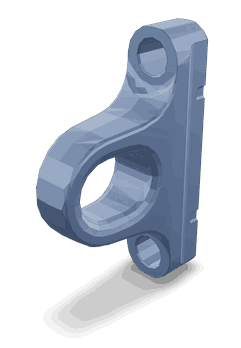

Engine Lifting Bracket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5375518 Engine Lifting Bracket is a specialized component designed for the maintenance and repair of commercial trucks equipped with Cummins engines. This part plays a significant role in facilitating the safe and efficient lifting and securing of the engine during various service procedures. Its design and construction are tailored to meet the demanding requirements of heavy-duty truck maintenance, ensuring both the safety of the technician and the integrity of the engine.

Purpose and Function

The primary purpose of the Cummins 5375518 Engine Lifting Bracket is to provide a secure point of attachment for lifting equipment during engine removal, installation, or servicing. This Cummins part is engineered to distribute the weight of the engine evenly, reducing the risk of damage to the engine or surrounding components. By offering a stable and reliable lifting point, it enhances the safety and efficiency of engine handling procedures.

Key Features

The Cummins 5375518 Engine Lifting Bracket is constructed from high-strength materials, ensuring durability and reliability under the stresses of heavy-duty use. Its design incorporates robust mounting points and a sturdy frame, which contribute to its ability to support the weight of the engine securely. Additionally, the bracket features a corrosion-resistant coating, which protects it from the harsh environments often encountered in commercial truck operations, thereby extending its service life 1.

Benefits

Utilizing the Cummins 5375518 Engine Lifting Bracket offers several advantages. It enhances safety during engine handling by providing a secure attachment point for lifting equipment, minimizing the risk of accidents. The bracket also contributes to the stability of the engine during lifting, which is crucial for preventing damage to the engine or surrounding components. Furthermore, it facilitates more efficient maintenance procedures by allowing for quicker and easier engine removal and installation 2.

Installation Process

Proper installation of the Cummins 5375518 Engine Lifting Bracket involves several steps. Initially, the engine bay should be inspected to ensure there is adequate space for the bracket. The necessary tools, such as wrenches and torque wrenches, should be gathered. Safety precautions, including wearing appropriate personal protective equipment (PPE) and ensuring the vehicle is securely supported on jack stands, must be observed. The bracket is then aligned with the designated mounting points on the engine and secured in place using the provided hardware, ensuring all fasteners are tightened to the specified torque settings 3.

Maintenance and Care

To ensure the longevity and optimal performance of the Cummins 5375518 Engine Lifting Bracket, regular maintenance and care are recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the bracket with a suitable solvent can help remove dirt and grime, preventing buildup that could compromise its structural integrity. Any signs of damage or corrosion should be addressed promptly to maintain the bracket’s effectiveness and safety.

Troubleshooting Common Issues

Common issues with the Cummins 5375518 Engine Lifting Bracket may include corrosion, wear on mounting points, or fastener loosening. Corrosion can often be mitigated through regular cleaning and application of a protective coating. Wear on mounting points may require replacement of the bracket or the use of additional support structures. Loose fasteners should be tightened to the manufacturer’s specified torque settings, and any damaged fasteners should be replaced. Safety considerations, such as ensuring the engine is securely supported during troubleshooting, are paramount.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality components for commercial vehicles. The company’s focus on innovation, quality, and customer satisfaction has established it as a trusted name in the industry, providing reliable solutions for the demanding requirements of commercial and industrial applications.

Cummins Engine Lifting Bracket 5375518 Compatibility

The Cummins Engine Lifting Bracket part number 5375518 is designed to be compatible with a range of Cummins engines, ensuring secure and efficient engine handling during maintenance and installation processes. This bracket is engineered to fit seamlessly with the following Cummins engine models:

Cummins QSK50

The Cummins QSK50 engine, known for its robust performance and reliability, is often used in heavy-duty applications such as marine and power generation. The Engine Lifting Bracket 5375518 is specifically designed to align with the structural integrity and mounting points of the QSK50, providing a stable platform for lifting and securing the engine during maintenance.

Cummins CM2350

The Cummins CM2350 engine is another high-performance engine, typically utilized in industrial and marine applications. The Engine Lifting Bracket 5375518 is engineered to fit the CM2350’s specific design, ensuring that it can handle the engine’s weight and dimensions effectively. This bracket is crucial for safe and efficient engine handling, minimizing the risk of damage during maintenance procedures.

Cummins K108

The Cummins K108 engine, a part of the K Series, is widely used in various applications including agricultural and industrial sectors. The Engine Lifting Bracket 5375518 is designed to integrate with the K108’s mounting points, providing a reliable solution for lifting and securing the engine. This ensures that maintenance can be performed safely and efficiently, reducing the potential for accidents or engine damage.

By ensuring compatibility with these engines, the Cummins Engine Lifting Bracket 5375518 provides a versatile and reliable solution for engine maintenance and installation across different applications.

Understanding the Role of Part 5375518 Engine Lifting Bracket in Engine Systems

The part 5375518 Engine Lifting Bracket is an essential component in the assembly and maintenance of various engine systems. This bracket is specifically designed to facilitate the safe and efficient lifting of engines during installation, removal, or maintenance procedures.

When integrating the 5375518 Engine Lifting Bracket with engine systems, it securely attaches to the engine block, providing a stable point for lifting equipment to engage. This ensures that the engine is lifted evenly, minimizing the risk of damage to the engine or surrounding components.

In conjunction with the engine hoist or crane, the lifting bracket allows for precise control during the lifting process. This is particularly important when working in confined spaces or when the engine is heavy and cumbersome.

Additionally, the bracket plays a role in aligning the engine with other components during installation. It helps ensure that the engine is positioned correctly relative to the transmission, exhaust system, and other critical parts, which is essential for proper engine function and performance.

The use of the 5375518 Engine Lifting Bracket also enhances safety by reducing the physical strain on mechanics. By providing a secure attachment point, it allows for the use of mechanical lifting equipment, which is safer and more efficient than manual lifting.

Overall, the 5375518 Engine Lifting Bracket is a valuable tool in the maintenance and repair of engine systems, offering both functional and safety benefits.

Conclusion

The Cummins 5375518 Engine Lifting Bracket is a critical component for the safe and efficient handling of engines during maintenance and repair procedures. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of safety and efficiency make it an indispensable tool for technicians working on heavy-duty commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.