This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

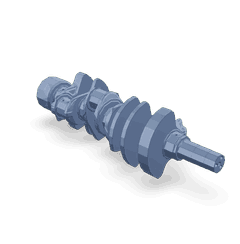

Introduction to Engine Crankshafts

An engine crankshaft is a fundamental component in internal combustion engines, responsible for converting the linear motion of the pistons into rotational motion. This rotational motion is essential for generating power, which drives the vehicle. The crankshaft serves as the backbone of the engine, supporting the pistons and connecting rods, and ensuring smooth and efficient operation 1.

The Role of the Cummins 5462513 Engine Crankshaft

The Cummins 5462513 engine crankshaft is specifically engineered for use in heavy-duty trucks and commercial vehicles. Designed to endure the high stresses and torques associated with heavy-duty operations, this crankshaft is pivotal in the engine’s operation. It converts the up-and-down motion of the pistons into rotational motion, which powers the vehicle. Its durability and precision are critical for maintaining engine efficiency and longevity, ensuring that the truck operates reliably under demanding conditions 2.

How the Cummins 5462513 Engine Crankshaft Works

The Cummins 5462513 engine crankshaft operates by harnessing the power generated from the combustion of fuel in the engine cylinders. As the pistons move downward due to the explosion of the air-fuel mixture, they push against the crankshaft, causing it to rotate. This rotational motion is then transmitted through the transmission and differential to the wheels, propelling the vehicle forward. The crankshaft’s balance and alignment are crucial for smooth engine operation, reducing wear and tear, and ensuring optimal performance 3.

Importance of the Cummins 5462513 Engine Crankshaft in Truck Operations

In the realm of commercial trucks, the engine crankshaft is indispensable for ensuring reliable and efficient operation. The high demands of heavy-duty applications necessitate a crankshaft that is robust and capable of handling significant loads and stresses. A well-functioning crankshaft ensures that the engine runs smoothly, providing the necessary power for the truck to operate effectively. It also contributes to fuel efficiency and reduces the likelihood of engine breakdowns, which is crucial for maintaining operational continuity in commercial settings.

Troubleshooting and Maintenance of the Cummins 5462513 Engine Crankshaft

Proper maintenance of the Cummins 5462513 engine crankshaft is essential for the longevity and performance of the engine. Regular inspections should be conducted to check for signs of wear, such as scoring or excessive play in the bearings. Lubrication is also critical, as it reduces friction and wear, ensuring smooth operation. If any issues are detected, such as unusual noises or vibrations, it is important to address them promptly to prevent further damage and ensure the crankshaft continues to perform optimally.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components, known for its innovation and quality. The company has a long history of producing reliable and high-performance engines for a variety of applications, including commercial trucks. Cummins’ commitment to research and development ensures that its products meet the highest standards of performance and durability, making it a trusted name in the industry.

Cummins Engine Crankshaft 5462513 Compatibility

The Cummins Engine Crankshaft part number 5462513 is a critical component designed to fit seamlessly within various engine configurations. This crankshaft is engineered to ensure optimal performance and durability, making it a suitable replacement or upgrade part for several engine models.

ISV (Nissan) Engines

The Cummins crankshaft 5462513 is compatible with the ISV engines produced by Nissan. These engines are known for their reliability and efficiency, often used in heavy-duty applications. The crankshaft’s design ensures it can handle the high stress and torque demands typical of these engines, providing a robust foundation for smooth operation.

Grouping by Application

For commercial and industrial applications, the 5462513 crankshaft is often used in:

- Heavy-Duty Trucks: Ensuring durability and longevity under heavy loads.

- Construction Equipment: Providing the necessary strength and reliability for demanding tasks.

- Marine Engines: Offering resistance to corrosion and wear, crucial for marine environments.

This crankshaft is engineered to fit precisely within the specified engine models, ensuring compatibility and performance. Its design allows for easy installation and integration, minimizing downtime and maximizing efficiency.

Role of Part 5462513 Engine Crankshaft in Engine Systems

The part 5462513 Engine Crankshaft is integral to the operation of various engine systems, working in concert with several key components to ensure efficient and reliable performance.

Interaction with the Block and Cylinder Block

The crankshaft is housed within the engine block, which serves as the structural backbone of the engine. The block is typically made from cast iron or aluminum and contains the cylinder bores where the pistons move. The crankshaft’s main bearings rest on journals within the block, allowing it to rotate smoothly. This rotation is essential for converting the linear motion of the pistons into rotational motion, which ultimately drives the vehicle.

Relationship with the Cylinder

Each cylinder in the engine houses a piston that is connected to the crankshaft via a connecting rod. As the air-fuel mixture in the cylinder combusts, it pushes the piston downward. This motion is transferred through the connecting rod to the crankshaft, causing it to rotate. The crankshaft’s design, including its counterweights and balance, helps to manage the forces generated by the pistons’ movement, ensuring smooth operation.

Integration with Long Block Kit

In a long block kit, which includes the engine block, crankshaft, pistons, connecting rods, camshaft, and valve train, the crankshaft plays a pivotal role. It acts as the central component around which these parts operate. The crankshaft’s precise engineering ensures that the timing of the pistons’ movements is synchronized with the opening and closing of the valves, allowing for optimal combustion efficiency and power output.

Function in Short Block Kit

A short block kit typically consists of the engine block, crankshaft, pistons, and connecting rods. Here, the crankshaft is essential for transforming the energy from the pistons’ movements into rotational force. Its integration with the short block kit lays the foundation for the engine’s mechanical operation, upon which additional components like the cylinder head and valve train can be installed to complete the engine assembly.

Conclusion

The Cummins 5462513 engine crankshaft is a critical component in the operation of heavy-duty trucks. Its design and engineering ensure that it can withstand the rigors of commercial use, providing the power and reliability needed for these vehicles. Proper maintenance and troubleshooting are essential for ensuring that the crankshaft continues to perform optimally, contributing to the overall efficiency and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.