This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

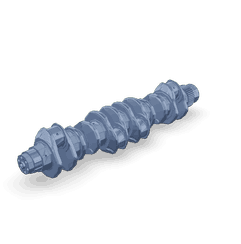

The Cummins 5486291 Engine Crankshaft is a critical component in the operation of commercial trucks, integral to the engine system’s efficient and reliable performance. Its design and functionality are essential for converting the linear motion of pistons into rotational motion, which drives the vehicle 1.

Basic Concepts of Engine Crankshafts

An engine crankshaft converts the linear motion of pistons into rotational motion, which is then used to drive the vehicle. Within an internal combustion engine, the crankshaft connects to the pistons via connecting rods. As the pistons move due to the combustion process, the crankshaft rotates, transferring power to the transmission and ultimately to the wheels 2.

Purpose of the Cummins 5486291 Engine Crankshaft

The Cummins 5486291 Engine Crankshaft is designed to enhance truck engine operation. It ensures smooth and consistent power delivery, contributing to engine performance and efficiency. The crankshaft’s role in converting piston motion into rotational force is essential for the engine’s overall functionality 3.

Key Features

The Cummins 5486291 Engine Crankshaft features high-quality materials, ensuring resilience under demanding conditions. Its design includes precise balancing and robust construction, contributing to reliability and longevity. These features enhance performance and durability 4.

Benefits

Utilizing the Cummins 5486291 Engine Crankshaft offers benefits such as improved engine efficiency, heightened reliability, and extended longevity. These advantages contribute to overall truck performance, ensuring smooth and efficient operation over extended periods 5.

Installation Process

Installing the Cummins 5486291 Engine Crankshaft requires careful preparation and appropriate tools. The process involves aligning the crankshaft with the engine block, securing it in place, and ensuring all connections are properly torqued. Safety precautions, such as wearing protective gear and ensuring the engine is cool, are imperative throughout the installation 6.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 5486291 Engine Crankshaft, regular maintenance is necessary. This includes inspecting the crankshaft for signs of wear or damage at recommended intervals, ensuring proper lubrication, and addressing any issues promptly to prevent further damage 7.

Troubleshooting Common Issues

Common issues with the Cummins 5486291 Engine Crankshaft may include misalignment, wear, or lubrication problems. Troubleshooting these issues involves a systematic approach to identify the root cause, whether it be improper installation, lack of maintenance, or operational stress. Solutions may range from realigning components to replacing worn parts or adjusting lubrication levels 8.

About Cummins

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality engine components. The company’s commitment to innovation and excellence is evident in its wide range of diesel engines and related technologies, making it a leading provider in the field 9.

Conclusion

The Cummins 5486291 Engine Crankshaft is a vital component for the efficient and reliable operation of commercial truck engines. Its design, featuring high-quality materials and precise engineering, ensures durability and performance. Regular maintenance and proper installation are crucial for maximizing the benefits of this part, contributing to the overall performance and longevity of truck engines.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

General Information. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666183.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

General Information. (n.d.). Operation and Maintenance Manual. Bulletin Number 3666183.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.