This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Engine Brake Adjusting Screw, Part #3083967 by Cummins, is designed to fine-tune the performance of the engine braking system in heavy-duty trucks. Cummins Inc., a leading manufacturer in the commercial truck industry, produces this part. The adjusting screw is integral to optimizing the engine braking system, which is vital for the safe and efficient operation of heavy-duty vehicles, particularly during descents.

Function and Operation

The Engine Brake Adjusting Screw operates within the engine braking system by modulating the performance of the engine brake. It adjusts the valve timing and pressure within the system, allowing for precise control over the engine’s braking force. This adjustment is crucial for maintaining optimal engine brake performance across varying driving conditions and load requirements 1.

Purpose of the Engine Brake Adjusting Screw

This Cummins part contributes to the efficiency and control of engine braking. It allows drivers to fine-tune the engine brake’s intensity, ensuring that the braking force is appropriate for the current driving conditions. This adjustment enhances the vehicle’s ability to safely manage speed on descents, reducing the reliance on the service brakes and thereby extending their lifespan 2.

Key Features

The primary characteristics of the Engine Brake Adjusting Screw include its robust design and high-quality materials, which ensure durability and reliability under the demanding conditions of heavy-duty truck operation. Its precise machining allows for accurate adjustments, and its integration into the engine braking system is designed to enhance functionality and performance 3.

Benefits

The advantages provided by the Engine Brake Adjusting Screw include improved engine brake performance, which contributes to enhanced safety during descents by allowing for better control of vehicle speed. Additionally, the efficient use of engine braking can lead to potential fuel savings by reducing the need for frequent service brake applications, which can cause increased fuel consumption 4.

Installation and Adjustment

Proper installation and adjustment of the Engine Brake Adjusting Screw involve several steps to ensure optimal performance. It is important to follow manufacturer guidelines for torque specifications and adjustment ranges. Best practices include verifying the screw’s position before and after adjustment and ensuring that all related components are in good working condition. Common pitfalls to avoid include over-tightening, which can lead to component damage, and incorrect adjustments, which can affect engine brake performance 5.

Troubleshooting and Maintenance

Identifying and resolving common issues related to the Engine Brake Adjusting Screw may involve checking for proper screw position, ensuring there is no damage to the screw or its associated components, and verifying that the engine braking system is functioning as intended. Regular maintenance includes inspecting the screw for wear or damage and ensuring that all adjustments are within the specified range. This proactive approach helps to maintain optimal performance and longevity of the engine braking system 6.

Safety Considerations

When working with the Engine Brake Adjusting Screw, it is important to observe safety protocols and precautions. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Operational safety measures involve ensuring that the vehicle is securely parked and the engine is off before beginning any work on the engine braking system. Following these safety guidelines helps to prevent accidents and ensures a safe working environment 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Their extensive product range and commitment to innovation underscore the quality and dependability of their components, including the Engine Brake Adjusting Screw.

Engine Brake Adjusting Screw (Part 3083967) in Cummins Engines

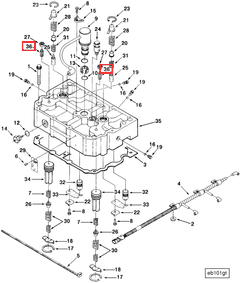

The Engine Brake Adjusting Screw, part number 3083967, is a critical component in the Cummins N14 CELECT PLUS engine. This part plays a pivotal role in the engine’s brake system, ensuring that the engine brake operates efficiently and reliably.

In the Cummins N14 CELECT PLUS engine, the Engine Brake Adjusting Screw is used to fine-tune the engine brake’s performance. This adjustment is crucial for maintaining optimal engine braking, which is essential for safety, especially in heavy-duty applications such as trucks and construction equipment.

The screw is designed to be easily accessible during routine maintenance, allowing technicians to make precise adjustments without extensive disassembly. This feature is particularly beneficial in the field, where quick and efficient repairs are necessary to minimize downtime.

For Cummins engines, the Engine Brake Adjusting Screw is a standardized component, ensuring compatibility across various models within the Cummins engine family. This standardization simplifies inventory management and ensures that technicians can use familiar tools and techniques across different engine types.

Role of Part 3083967 Engine Brake Adjusting Screw in Engine Systems

The Engine Brake Adjusting Screw is an integral component in the fine-tuning and maintenance of various engine brake systems. This screw plays a significant role in ensuring the optimal performance and efficiency of the brake system within the engine.

Interaction with Brake Systems

In brake systems, the Engine Brake Adjusting Screw is used to make precise adjustments to the brake mechanism. This ensures that the brake applies the correct amount of force, providing reliable stopping power without causing undue wear on the brake components. Proper adjustment is essential for maintaining the balance between braking efficiency and component longevity 8.

Cummins Engine Brake Kit Integration

When incorporated into a Cummins Engine Brake Kit, the Engine Brake Adjusting Screw allows for the calibration of the engine brake’s performance. This screw enables technicians to fine-tune the brake’s engagement points and release timing, which is vital for achieving the desired engine deceleration rates. This adjustment is particularly important in heavy-duty applications where precise control over vehicle speed and stopping distance is necessary 9.

Engine Brake System Optimization

Within the broader context of engine brake systems, the Engine Brake Adjusting Screw facilitates the optimization of the brake’s operational parameters. By allowing for micro-adjustments, this component ensures that the engine brake operates within its specified performance envelope. This is especially important in scenarios where the engine brake is used frequently, such as in towing or downhill driving, where consistent and reliable performance is paramount 10.

Overall Engine Performance

The Engine Brake Adjusting Screw also contributes to the overall performance and durability of the engine. By ensuring that the engine brake system is properly calibrated, this component helps prevent unnecessary strain on the engine and other related systems. This, in turn, promotes smoother operation and extends the lifespan of the engine components 11.

Conclusion

The Engine Brake Adjusting Screw, Part #3083967 by Cummins, is a vital component in the engine braking system of heavy-duty trucks. Its role in modulating engine brake performance ensures safety and efficiency during vehicle operation, particularly on descents. The screw’s design allows for precise adjustments, contributing to the overall reliability and performance of the engine. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Thorsten Boger, Willard Cutler. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

A. J. Wharton. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250, Bulletin Number 4310666, Operation and Maintenance Manual.

↩ -

Thorsten Boger, Willard Cutler. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

A. J. Wharton. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.