3045533

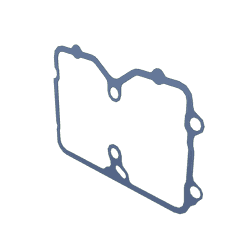

Engine Brake Housing Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3045533 Engine Brake Housing Gasket, manufactured by Cummins, is a component designed to enhance the operation of heavy-duty trucks. Cummins, a well-established name in the diesel engine manufacturing industry, produces this gasket to ensure the efficient functioning of engine braking systems in trucks. This Cummins part plays a significant role in maintaining the integrity of the engine braking mechanism, contributing to both the performance and safety of the vehicle 1.

Basic Concepts of Engine Brake Housing Gaskets

An Engine Brake Housing Gasket is a sealing component used within the engine braking system. Its primary function is to create a secure seal between the engine brake housing and other engine components. This seal is vital for the effective operation of the engine braking system, which uses the engine as a compressor to slow down the vehicle, thereby reducing wear on the transmission and brakes. The gasket contributes to the overall performance and safety of the vehicle by ensuring that the engine braking system functions as intended 2.

Purpose of the 3045533 Engine Brake Housing Gasket

The 3045533 Engine Brake Housing Gasket serves a specific role in the operation of a truck. It is designed to seal the engine brake housing, which is a critical component in the engine braking system. By providing a reliable seal, the gasket ensures that the engine braking system operates efficiently, allowing for effective deceleration of the vehicle without undue stress on the transmission or braking system. This contributes to the overall safety and performance of the truck 3.

Key Features

The 3045533 Engine Brake Housing Gasket boasts several key features that enhance its performance and durability. These include a material composition that is resistant to high temperatures and pressures, ensuring longevity and reliability. The design specifications of the gasket are tailored to fit precisely within the engine brake housing, providing an effective seal. Additionally, any unique attributes, such as reinforced edges or specialized coatings, further contribute to its performance and durability.

Benefits

Using the 3045533 Engine Brake Housing Gasket offers several benefits. It contributes to improved engine efficiency by ensuring that the engine braking system operates effectively. Enhanced safety is another advantage, as the gasket helps to maintain the integrity of the engine braking system, reducing the risk of accidents due to brake failure. Additionally, the gasket can lead to potential cost savings due to reduced maintenance needs, as its durable construction minimizes the frequency of replacements.

Installation Process

Proper installation of the 3045533 Engine Brake Housing Gasket is crucial for its effective functioning. The process involves several steps, including preparatory actions such as cleaning the mating surfaces to ensure a proper seal. Tools required may include gasket scrapers and torque wrenches. Best practices for installation include ensuring that the gasket is correctly aligned and that all fasteners are tightened to the manufacturer’s specifications to achieve a secure and effective seal.

Troubleshooting Common Issues

Common problems associated with Engine Brake Housing Gaskets include leaks or failure to seal properly. These issues can often be diagnosed through visual inspection or by monitoring the performance of the engine braking system. Troubleshooting steps may involve checking for proper installation, inspecting the gasket for signs of wear or damage, and ensuring that all mating surfaces are clean and free of debris. Addressing these issues promptly can help maintain the efficiency and safety of the engine braking system.

Maintenance Tips

Regular maintenance of the 3045533 Engine Brake Housing Gasket is important to ensure optimal performance. This includes inspecting the gasket at recommended intervals for signs of wear or damage. If any issues are detected, such as leaks or compromised sealing surfaces, the gasket should be replaced to maintain the integrity of the engine braking system. Following these maintenance tips can help extend the lifespan of the gasket and ensure the continued safe and efficient operation of the truck.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and quality. The company is known for its expertise in producing high-quality components for the automotive industry, including a wide range of gaskets and seals. Cummins’ commitment to quality and performance is evident in its products, which are designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3045533 Engine Brake Housing Gasket in Engine Systems

The 3045533 Engine Brake Housing Gasket is an essential component in the assembly and operation of various engine systems, particularly those involving the engine brake mechanism. This gasket is designed to ensure a secure and sealed fit between the engine brake housing and the engine block or other mating surfaces.

In the context of the 425A 24VDC S/L Stand Kit, the gasket plays a supportive role by maintaining the integrity of the engine brake system when the engine is mounted on the stand. It ensures that there are no leaks or gaps that could affect the performance or safety of the engine during testing or maintenance procedures.

When integrated with the Brake Overhead Gasket Set, the 3045533 gasket complements the set by providing additional sealing at the brake housing. This is particularly important in high-stress environments where the engine brake is frequently engaged, as it helps to maintain consistent pressure and performance.

For the Engine Brake itself, the gasket is a fundamental component that ensures the brake housing remains sealed against the engine block. This sealing is vital for the effective operation of the engine brake, as it prevents any loss of compression that could reduce the braking efficiency.

In the MD 425A 12VDC Stand Kit, the gasket ensures that when the engine is mounted for either testing or operational use, the engine brake system remains sealed and functional. This is important for maintaining the overall performance and reliability of the engine under various conditions.

Lastly, in the MD425A 12VDC Colmt K120 system, the gasket ensures that the engine brake housing is properly sealed, which is essential for the efficient operation of the engine brake in this specific configuration. This sealing helps in maintaining the desired braking performance and protecting the engine components from potential damage due to leaks or improper sealing.

Conclusion

The 3045533 Engine Brake Housing Gasket is a critical component in the operation of heavy-duty trucks, ensuring the efficient and safe functioning of the engine braking system. Its role in maintaining the integrity of the engine brake housing and sealing it against the engine block is vital for the overall performance and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the longevity and reliability of the truck’s engine system.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.