4935680

Engine Lifting Bracket

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

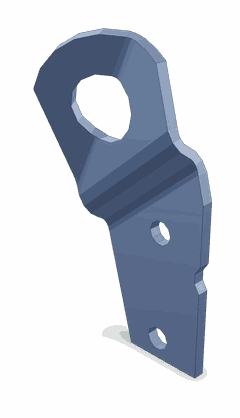

The Engine Lifting Bracket, part #4935680, manufactured by Cummins, is a specialized component designed for use in heavy-duty truck maintenance and repair. This part plays a role in facilitating the safe and efficient handling of engines during various maintenance or replacement procedures.

Purpose of the Engine Lifting Bracket

The Engine Lifting Bracket serves a specific function in the context of heavy-duty truck engines. It aids in the secure lifting of the engine, allowing mechanics to perform necessary maintenance or replacement tasks with greater ease and safety. By providing a stable point of attachment for lifting equipment, this Cummins part helps to distribute the weight of the engine evenly, reducing the risk of damage to the engine or injury to the technician 1.

Key Features

The design and material characteristics of the Engine Lifting Bracket contribute to its effectiveness and reliability. Crafted from high-strength materials, this bracket is built to withstand the rigors of heavy-duty use. Its design ensures compatibility with Cummins engines, offering a precise fit that enhances the stability and security of the lifting process. The bracket’s durability and strength are paramount, ensuring it can support the weight of heavy-duty truck engines without deformation or failure 2.

Benefits of Using the Engine Lifting Bracket

Incorporating the Engine Lifting Bracket into maintenance procedures offers several advantages. It enhances safety during engine handling by providing a secure attachment point for lifting equipment. This reduces the likelihood of accidents or injuries associated with unstable lifting practices. Additionally, the use of this bracket can lead to a reduction in maintenance time, as it streamlines the engine lifting process. For fleet operators, this can translate into potential cost savings by minimizing downtime and improving the efficiency of maintenance operations 3.

Installation Process

Proper installation of the Engine Lifting Bracket is crucial for its optimal performance and safety. The installation process involves securing the bracket to the engine in the designated location, ensuring it is correctly positioned and tightly fastened. This may require the use of specific tools and adherence to manufacturer guidelines to ensure the bracket is installed correctly and can support the engine’s weight during lifting operations.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Engine Lifting Bracket are recommended to ensure its continued reliability and safety. This includes checking for signs of wear or damage, ensuring all fasteners are tight, and verifying that the bracket remains securely attached to the engine. Common issues may include loosening of fasteners or damage to the bracket itself, which can often be addressed through re-tightening or replacement as necessary.

Safety Considerations

When using the Engine Lifting Bracket, it is important to follow safety guidelines to prevent accidents and injuries. This includes ensuring that all personnel involved in the lifting process are properly trained in the use of lifting equipment and the bracket itself. Adhering to safety protocols, such as using the correct lifting equipment and ensuring the area is clear of obstacles, is vital. Additionally, regular inspections of the bracket and lifting equipment should be conducted to identify any potential safety hazards before they become a problem.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s commitment to advancing engine technology is evident in its wide range of products, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks. Cummins’ dedication to quality is reflected in the design and manufacturing of components like the Engine Lifting Bracket, ensuring they meet the high standards expected by professionals in the field.

Compatibility with Cummins Engines

The Cummins Engine Lifting Bracket part number 4935680 is designed to fit a variety of Cummins engine models. This bracket is essential for safely lifting and supporting the engine during maintenance and installation processes. Below is a detailed breakdown of the engine models that this lifting bracket is compatible with:

6C Series

- 6C8.3

- QSC8.3 CM2880 C102

- QSC8.3 CM850 (CM2850)

ISC Series

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

ISL Series

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

L Series

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L9 CM2670 L128B

- L9.5 L117

QSL Series

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

QSC/QSL Series

- QSC9 CM2250 / QSL9 CM2250

This lifting bracket is engineered to provide a secure and stable platform for handling these engines, ensuring that the installation and maintenance processes are performed safely and efficiently. The bracket’s design accommodates the specific dimensions and mounting points of the listed engine models, making it a versatile and reliable component for Cummins engine maintenance.

Role of Part 4935680 Engine Lifting Bracket in Engine Systems

The Engine Lifting Bracket, identified by part number 4935680, is a component in the arrangement and lifting processes of various engine systems. This bracket is designed to provide a secure and stable attachment point for lifting equipment, ensuring that the engine can be safely and efficiently moved or positioned during maintenance, repair, or installation procedures.

When integrating the Engine Lifting Bracket into an engine system, it is typically mounted at specific points on the engine block or frame. This strategic placement allows for even distribution of the lifting force, minimizing the risk of damage to the engine components during the lifting process. The bracket works in conjunction with lifting equipment such as cranes, hoists, or jacks, providing a reliable interface that enhances the safety and effectiveness of engine handling operations.

In practical applications, the Engine Lifting Bracket is used in a variety of scenarios, including:

- Engine Replacement: During the removal and installation of an engine, the bracket ensures that the engine is lifted smoothly and without undue stress on its components.

- Maintenance and Repair: When an engine needs to be accessed for maintenance or repair, the bracket facilitates the safe lifting of the engine to the required height, allowing mechanics to work underneath or around it.

- Transportation: In situations where an engine needs to be transported within a facility or to another location, the bracket provides a secure attachment point for lifting and moving the engine.

The effective use of the Engine Lifting Bracket in these scenarios underscores its importance in maintaining the integrity and safety of engine systems during various operational procedures.

Conclusion

The Engine Lifting Bracket part #4935680 is a vital component in the maintenance and repair of heavy-duty truck engines. Its design and functionality contribute to safer, more efficient engine handling processes, reducing the risk of damage to the engine and injury to technicians. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.