This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4089738 Engine Piston Kit is a specialized component designed for heavy-duty truck engines. It is engineered to enhance performance and reliability by ensuring efficient combustion and smooth operation. This part is significant in maintaining the high standards of power and durability expected in heavy-duty applications.

Basic Concepts of Engine Piston Kits

An engine piston kit typically includes pistons, piston rings, wrist pins, and other related components. These parts work together within an internal combustion engine to convert the energy from fuel combustion into mechanical motion. The piston moves up and down in the cylinder, driven by the expanding gases from the combustion process, which in turn drives the crankshaft and ultimately powers the vehicle 1.

Purpose of the Cummins 4089738 Engine Piston Kit

This Cummins part plays a role in the operation of a truck by facilitating the combustion process and contributing to overall engine performance. It ensures that the pistons move efficiently within the cylinders, maintaining proper compression and allowing for effective energy transfer from the combustion chamber to the crankshaft. This kit is integral to achieving optimal engine efficiency and reliability.

Key Features

The Cummins 4089738 Engine Piston Kit is characterized by its high-quality material composition, which typically includes durable alloys designed to withstand the high temperatures and pressures of heavy-duty engine operation. Design enhancements may include improved piston ring profiles for better sealing and reduced friction, as well as advanced wrist pin designs for enhanced durability. These features differentiate the kit from other piston kits by providing superior performance and longevity 2.

Benefits

Using the Cummins 4089738 Engine Piston Kit can lead to improved engine efficiency, as the high-quality materials and design enhancements contribute to reduced friction and better combustion efficiency. Additionally, the durability of the components can result in longer engine life and reduced maintenance costs for fleet operators. The potential cost savings from increased engine reliability and performance make this kit a valuable investment 3.

Installation Process

Installing the Cummins 4089738 Engine Piston Kit involves several steps. Mechanics and engineers should begin by ensuring the engine is properly prepared, which includes cleaning the cylinder bores and inspecting other related components for wear or damage. The pistons should be carefully installed with the rings aligned correctly, followed by the wrist pins. It is important to torque all fasteners to the manufacturer’s specifications and to perform a thorough inspection before reassembling the engine. Best practices include using the appropriate tools and following a systematic approach to ensure a successful installation 4.

Troubleshooting and Maintenance

Common issues with engine piston kits may include piston ring failure, wrist pin wear, or piston skirt damage. Troubleshooting these issues involves inspecting the components for signs of wear, measuring clearances, and checking for proper fit and function. Regular maintenance practices, such as monitoring engine performance, checking oil levels, and performing routine inspections, can help ensure the longevity and optimal performance of the piston kit. Addressing issues promptly and following recommended maintenance schedules are key to preventing major problems 5.

Performance Enhancements

The Cummins 4089738 Engine Piston Kit contributes to enhanced engine performance by improving power output, fuel efficiency, and reliability. The design and material improvements allow for more efficient combustion and reduced mechanical losses, leading to better overall engine performance. Fleet operators can expect increased productivity and reduced downtime with the use of this high-quality piston kit.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing reliable and high-performance engines and components. The company’s commitment to innovation and quality is evident in its wide range of products, including the Cummins 4089738 Engine Piston Kit.

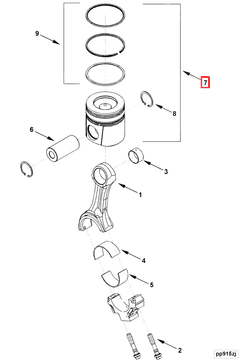

Components of Cummins Engine Piston Kit 4089738

Retaining Ring (3939375)

The retaining ring is a critical component within the Cummins Engine Piston Kit 4089738. Its primary role is to secure and maintain the position of other components, ensuring they remain in place during engine operation. This ring is essential for the structural integrity of the piston assembly, preventing components from dislodging or moving out of alignment, which could lead to engine failure.

Engine Piston (3970841)

The engine piston is the central component of the kit. It is responsible for converting the pressure from the combustion of fuel into mechanical force, which drives the crankshaft. The piston’s design and material are crucial for withstanding high temperatures and pressures, ensuring efficient and reliable engine performance. Its precise fit within the cylinder is vital for minimizing friction and maximizing efficiency.

Piston Ring Set (3804932)

The piston ring set includes multiple rings that play a vital role in the engine’s operation. These rings seal the combustion chamber, preventing gas leakage and ensuring optimal compression. They also help in controlling oil consumption by scraping excess oil from the cylinder walls, which reduces emissions and enhances engine longevity. The piston ring set is designed to withstand the extreme conditions within the engine, providing a durable and reliable seal.

Conclusion

The Cummins 4089738 Engine Piston Kit is a vital component for heavy-duty truck engines, offering enhanced performance, reliability, and efficiency. Its high-quality materials and design features contribute to improved engine operation, making it a valuable investment for fleet operators. Proper installation, maintenance, and troubleshooting are essential to maximizing the benefits of this part.

-

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISB/ISD6.7 CM2880 B126. Bulletin Number 4383694.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.