This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2887954 Exhaust Valve is a component designed for use in commercial trucks, playing a significant role in the efficient operation of diesel engines. This valve is integral to the engine’s ability to expel exhaust gases, thereby contributing to the overall performance and efficiency of the vehicle.

Basic Concepts of Exhaust Valves

An exhaust valve is a component within an internal combustion engine that allows the release of exhaust gases from the combustion chamber into the exhaust system. During the engine cycle, specifically at the end of the power stroke, the exhaust valve opens to allow the expulsion of spent gases. This action is crucial for the engine’s operation, as it clears the combustion chamber for the next intake of air and fuel 1.

Role of the 2887954 Exhaust Valve in Truck Operation

The Cummins 2887954 Exhaust Valve is specifically engineered to enhance the engine’s operation in commercial trucks. By efficiently managing the expulsion of exhaust gases, it contributes to the engine’s efficiency and performance. This valve’s design allows for optimal gas flow, which is vital for maintaining engine power and reducing emissions 2.

Key Features of the 2887954 Exhaust Valve

The Cummins 2887954 Exhaust Valve incorporates several design and material features that enhance its durability, performance, and reliability. These features include a robust construction that withstands high temperatures and pressures, precision machining for accurate seating, and materials selected for their resistance to wear and corrosion. These attributes ensure the valve can operate effectively under the demanding conditions encountered in commercial truck engines 3.

Benefits of Using the 2887954 Exhaust Valve

Utilizing the Cummins 2887954 Exhaust Valve offers several advantages. These include improved engine performance due to efficient exhaust gas expulsion, increased fuel efficiency as a result of optimized engine operation, and reduced emissions, contributing to a cleaner operating environment. The valve’s design also supports longer engine life by ensuring consistent and reliable performance.

Installation and Integration

Proper installation of the Cummins 2887954 Exhaust Valve is crucial for ensuring its effective operation within a truck’s engine system. Installation guidelines recommend following manufacturer specifications for torque settings and seating procedures to ensure a secure and proper fit. Specific considerations may include the valve’s orientation and the condition of the valve seat to ensure a leak-free seal.

Maintenance and Care

Routine maintenance and care of the Cummins 2887954 Exhaust Valve are essential for ensuring its longevity and optimal performance. Recommendations include regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove any deposits that may affect performance, and following manufacturer guidelines for any necessary adjustments or replacements.

Troubleshooting Common Issues

Common problems associated with exhaust valves can include leaks, sticking, or failure to seat properly. Potential causes may range from manufacturing defects to operational wear and tear. Troubleshooting steps may involve inspecting the valve and seat for damage, cleaning or replacing components as necessary, and ensuring proper installation and maintenance practices are followed.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power generation and propulsion systems. With a history of innovation and quality, Cummins offers a comprehensive product range that includes diesel engines, natural gas engines, and related technologies. The company’s commitment to excellence is evident in its approach to manufacturing, ensuring that components like the 2887954 Exhaust Valve meet high standards of performance and reliability.

Exhaust Valve 2887954 Compatibility with Cummins Engines

The Exhaust Valve 2887954, manufactured by Cummins, is a critical component in the engine’s operation, ensuring efficient exhaust gas expulsion and maintaining optimal engine performance. This part is designed to fit seamlessly within various Cummins engine models, enhancing their reliability and efficiency.

ISX12 G

The ISX12 G engine benefits from the Exhaust Valve 2887954, which is engineered to handle the high-pressure and high-temperature conditions typical of this engine model. The valve’s precision design ensures a tight seal, preventing exhaust gas leaks and maintaining the engine’s power output.

CM2180

In the CM2180 engine, the Exhaust Valve 2887954 plays a crucial role in the exhaust system. Its robust construction and precise fitment are essential for the engine’s smooth operation, contributing to its overall efficiency and longevity.

EJ

The EJ engine also relies on the Exhaust Valve 2887954 for its exhaust management. This valve’s compatibility with the EJ engine ensures that the engine operates at peak performance, with minimal exhaust gas emissions and maximum power delivery.

By integrating the Exhaust Valve 2887954 into these engines, Cummins ensures that each model maintains its intended performance standards, providing reliable and efficient operation across various applications.

Role of Part 2887954 Exhaust Valve in Engine Systems

The part 2887954 Exhaust Valve is an integral component within the engine system, working in concert with several other parts to ensure optimal engine performance and efficiency.

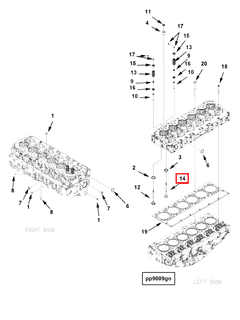

Interaction with Cylinder Head

The Exhaust Valve is mounted within the cylinder head, where it plays a significant role in the engine’s operation. As the valve opens and closes, it allows the expulsion of exhaust gases from the combustion chamber, facilitating the intake of fresh air-fuel mixture in the subsequent cycle. The precision fit and seal of the Exhaust Valve within the cylinder head are essential for maintaining compression and ensuring efficient combustion.

Integration with Cylinder Top Level Assembly Head

In engines with a cylinder top level assembly head, the Exhaust Valve is a key element. This assembly often includes components like the valve springs, retainers, and seals, all of which work together to control the valve’s movement. The Exhaust Valve must operate in harmony with these components to prevent issues such as valve float or burning, which can lead to decreased engine performance and potential damage.

Exhaust Valve Kit Compatibility

When part of an exhaust valve kit, the 2887954 Exhaust Valve is designed to work seamlessly with other components included in the kit. These kits often contain matched sets of intake and exhaust valves, along with necessary springs and seals. The Exhaust Valve’s design and material properties are tailored to complement these components, ensuring reliable operation under various engine conditions.

Performance Parts Synergy

In high-performance engine builds, the Exhaust Valve is often upgraded to handle increased stress and higher temperatures. When paired with other performance parts such as high-flow cylinder heads or advanced camshafts, the Exhaust Valve must be capable of withstanding greater forces and operating at higher speeds. This synergy enhances the engine’s power output and efficiency, provided all components are meticulously matched.

Coordination with Piston Cooling Nozzle

The Exhaust Valve also indirectly interacts with the piston cooling nozzle. Efficient exhaust gas flow, managed by the Exhaust Valve, helps in maintaining optimal cylinder pressures and temperatures. This, in turn, supports the effective operation of the piston cooling nozzle, which sprays oil to cool the piston underside. Proper Exhaust Valve function ensures that the engine operates within its designed thermal parameters, aiding in the longevity and performance of the piston cooling system.

Conclusion

The Cummins 2887954 Exhaust Valve is a critical component in the operation of commercial truck engines, contributing to efficient exhaust gas expulsion, improved engine performance, and reduced emissions. Its robust design, precision machining, and material selection ensure durability and reliability under demanding conditions. Proper installation, maintenance, and troubleshooting are essential for maximizing the valve’s performance and longevity.

-

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.