This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

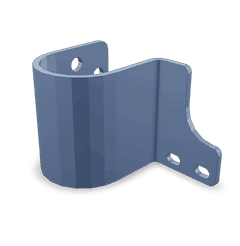

The Exhaust Connection Support 2891869 is a component designed by Cummins, a leading manufacturer in the diesel engine and component industry. This part is integral to the exhaust system, where it supports the connection between various exhaust components, ensuring structural integrity and efficient exhaust flow 1.

Function and Operation

The Exhaust Connection Support operates by providing a stable connection point within the exhaust system. It plays a role in maintaining the structural integrity of the exhaust components by securing them in place. Additionally, it facilitates efficient exhaust flow by ensuring that the connections remain tight and secure, which helps in reducing backpressure and enhancing the overall performance of the exhaust system 2.

Key Features

The design of the Exhaust Connection Support incorporates several features that enhance its functionality. It is constructed from materials that offer high durability and resistance to the extreme temperatures typically encountered in exhaust systems. These materials ensure that the support can withstand the thermal stresses without degrading over time. Furthermore, the Exhaust Connection Support is engineered to be compatible with Cummins engines, ensuring seamless integration and optimal performance 3.

Benefits

The Exhaust Connection Support provides several advantages. By maintaining secure connections, it contributes to improved exhaust system performance and reduces the risk of leaks. This not only enhances engine efficiency but also ensures that the exhaust system operates within the designed parameters, leading to better overall engine performance 4.

Installation and Compatibility

Proper installation of the Exhaust Connection Support is crucial for its effective functioning. It should be installed according to the manufacturer’s guidelines to ensure that it fits securely and functions as intended. Compatibility with various truck models and engine types is an important consideration, and the Exhaust Connection Support is designed to work with a range of Cummins engines, ensuring broad applicability across different vehicle platforms 5.

Maintenance and Troubleshooting

Regular maintenance of the Exhaust Connection Support is recommended to ensure its longevity and effectiveness. This includes periodic inspections for signs of wear or damage and ensuring that all connections remain tight. Common issues may include loosening of connections or material degradation, which can be addressed by re-tightening or replacing the support as necessary 6.

Safety Considerations

When working with the Exhaust Connection Support, it is important to observe several safety precautions. Handling hot components requires the use of appropriate personal protective equipment to avoid burns. Additionally, ensuring proper system sealing is vital to prevent exhaust leaks, which can pose health and safety risks 7.

Environmental Impact

The Exhaust Connection Support contributes to reducing emissions and improving fuel efficiency. By ensuring efficient exhaust flow and secure connections, it helps in maintaining the exhaust system’s performance, which aligns with environmental regulations and standards aimed at reducing harmful emissions 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the industry, continually advancing technology to meet the evolving needs of its customers 9.

Conclusion

The Exhaust Connection Support 2891869 by Cummins is a vital component in the exhaust system, offering structural integrity, efficient exhaust flow, and compatibility with various Cummins engines. Its proper installation, maintenance, and adherence to safety protocols ensure optimal performance and environmental compliance.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Cummins Inc. Company Overview. Available at: https://www.cummins.com/company/overview (Accessed: 10 October 2023).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.