This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

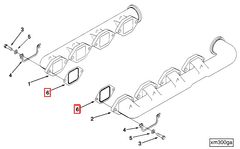

The Exhaust Collector Connection Assembly, identified by part number 3014617, is a component manufactured by Cummins, a leader in the commercial truck industry. This assembly plays a significant role in the exhaust system by facilitating the collection and direction of exhaust gases from the engine. Cummins is renowned for its commitment to innovation and quality, ensuring that its parts contribute to the efficient and reliable operation of heavy-duty trucks 1.

Function and Operation

The Exhaust Collector Connection Assembly operates by collecting exhaust gases from multiple cylinders and directing them into the exhaust system. This assembly ensures that the gases are efficiently channeled away from the engine, reducing backpressure and enhancing the overall performance of the exhaust system. By maintaining a smooth flow of exhaust gases, the assembly contributes to the engine’s efficiency and power output 2.

Key Features

The Exhaust Collector Connection Assembly is designed with several key features that enhance its performance. It is constructed from high-quality materials, such as durable alloys, to withstand the high temperatures and pressures of the exhaust system. The design includes precise engineering to ensure a secure fit and optimal gas flow. Additionally, the assembly may incorporate features such as heat shielding to protect surrounding components from excessive heat 3.

Benefits

The advantages of the Exhaust Collector Connection Assembly include improved exhaust flow, which leads to reduced backpressure and enhanced engine performance. By efficiently managing exhaust gases, the assembly contributes to lower emissions, helping the vehicle meet stringent environmental regulations. Furthermore, the durable construction of the assembly ensures long-lasting performance, reducing the need for frequent replacements and maintenance 4.

Installation and Compatibility

Proper installation of the Exhaust Collector Connection Assembly is crucial for its effective operation. It is important to follow the manufacturer’s guidelines to ensure a secure and correct fit. Compatibility with specific engine models and configurations should be verified to ensure optimal performance and integration within the exhaust system.

Maintenance and Troubleshooting

Routine maintenance of the Exhaust Collector Connection Assembly involves inspecting for signs of wear, corrosion, or damage. Regular cleaning and checking for proper alignment can help maintain its efficiency. Common issues may include leaks or blockages, which can be addressed by tightening connections or clearing obstructions. If problems persist, consulting the manufacturer’s guidelines or a professional technician is recommended.

Regulatory Compliance

The Exhaust Collector Connection Assembly plays a role in helping vehicles meet emissions regulations and standards. By ensuring efficient exhaust gas management, the assembly contributes to reduced emissions, which is vital for compliance with environmental regulations in the trucking industry. Adhering to these regulations is important for maintaining the environmental sustainability of commercial operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for innovation, quality, and reliability in the commercial truck industry. The company’s commitment to advancing technology and meeting the needs of its customers underscores its leadership in the market.

Application in Cummins Engines

The Exhaust Collector Connection Assembly 3014617 is compatible with several Cummins engine models, including but not limited to:

- V903

This part is engineered to fit seamlessly within the exhaust system architecture of these engines, providing a reliable connection point that can withstand the high temperatures and pressures typical of engine exhaust systems.

Integration with the Aftercooler

In systems equipped with an aftercooler, the Exhaust Collector Connection Assembly facilitates the routing of exhaust gases from the engine cylinders to the aftercooler. The aftercooler is designed to reduce the temperature of the exhaust gases, which enhances engine efficiency and reduces emissions. The connection assembly ensures that the transition from the manifold to the aftercooler is smooth, minimizing pressure drops and maintaining the integrity of the exhaust flow.

Role in the Exhaust Collector

The Exhaust Collector Connection Assembly is also responsible for connecting the exhaust manifold to the exhaust collector. The collector aggregates exhaust gases from multiple cylinders, optimizing the flow towards the turbocharger (if present) or directly to the exhaust system. This assembly ensures that the connection is robust, capable of withstanding high temperatures and pressures, and resistant to vibrations that could otherwise lead to leaks or failures.

Enhancing System Performance

By providing a reliable connection, the Exhaust Collector Connection Assembly contributes to the overall performance and durability of the exhaust system. It allows for efficient exhaust gas scavenging, which is essential for maintaining engine power and responsiveness. Additionally, it plays a part in reducing backpressure, which can otherwise impede engine performance and fuel efficiency.

Conclusion

The Exhaust Collector Connection Assembly (Part 3014617) is a key component in the exhaust system, particularly in engines with aftercoolers. Its role in ensuring a secure and efficient connection between the exhaust manifold and the exhaust collector is essential for optimal engine performance and durability.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.