This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

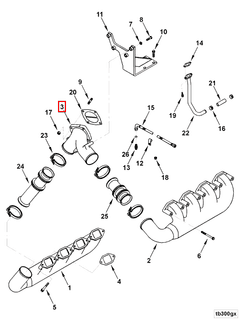

The Exhaust Collector Connection, part number 3088221, is a component designed by Cummins for use in the exhaust systems of heavy-duty trucks. This Cummins part is integral to the efficient operation of the exhaust system, facilitating the management and flow of exhaust gases from the engine. Its role is significant in maintaining the performance and efficiency of the truck’s engine 1.

Basic Concepts of Exhaust Collector Connection

An Exhaust Collector Connection serves as a junction point in the exhaust system where multiple exhaust pipes converge. Its function is to collect exhaust gases from various cylinders and direct them into the main exhaust pipe. This consolidation aids in the efficient expulsion of gases, reducing backpressure and enhancing engine performance. The connection also plays a role in managing the temperature and pressure of the exhaust gases, contributing to the overall efficiency of the exhaust system 2.

Purpose of the 3088221 Exhaust Collector Connection

The 3088221 Exhaust Collector Connection is specifically designed to enhance the operation of heavy-duty trucks. It plays a role in the exhaust system by ensuring a smooth and efficient flow of exhaust gases from the engine. This component contributes to the overall engine performance by reducing backpressure, which can otherwise impede engine efficiency and power output. Additionally, it aids in maintaining the structural integrity of the exhaust system by evenly distributing exhaust gas pressure 3.

Key Features

The 3088221 Exhaust Collector Connection is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and high temperatures, ensuring longevity in demanding environments. The design includes precise engineering to facilitate optimal exhaust gas flow and reduce the likelihood of leaks. Additionally, it features robust connections to withstand the vibrations and stresses inherent in heavy-duty truck operations 4.

Benefits

The use of the 3088221 Exhaust Collector Connection offers several benefits. It improves exhaust flow, which can lead to enhanced engine efficiency and performance. By efficiently managing exhaust gases, it contributes to reduced emissions, aligning with environmental regulations. The durable construction of the connection ensures longevity, reducing the need for frequent replacements and maintenance. Furthermore, its design helps in maintaining the overall health of the exhaust system components 5.

Installation Process

Installing the 3088221 Exhaust Collector Connection requires careful attention to detail to ensure a secure and effective fit. The process involves disconnecting the old connection, cleaning the mating surfaces, and aligning the new connection with the exhaust system. Tools such as wrenches and gasket sealant may be required. It is important to follow the manufacturer’s guidelines to ensure proper installation, which includes torquing bolts to the specified settings and checking for leaks after installation 6.

Common Issues and Troubleshooting

Common issues with the 3088221 Exhaust Collector Connection may include leaks, corrosion, or blockages. Leaks can often be addressed by re-torquing the connection or applying a high-temperature sealant. Corrosion may require cleaning the affected area and applying a protective coating. Blockages can be resolved by inspecting the connection for debris and clearing any obstructions. Regular inspections can help identify and address these issues before they lead to more significant problems 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 3088221 Exhaust Collector Connection, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the connection and surrounding areas can prevent the buildup of debris that may lead to blockages. Additionally, following the manufacturer’s guidelines for replacement intervals can help maintain the efficiency and safety of the exhaust system 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the production of diesel engines and related components. The company’s commitment to excellence and customer satisfaction is evident in its wide range of products designed to meet the demanding requirements of various applications, including heavy-duty trucks 9.

Role of Part 3088221 Exhaust Collector Connection in Engine Systems

The Exhaust Collector Connection, identified by part number 3088221, is integral to the efficient operation of several key components within an engine system. Its primary function is to facilitate the seamless transfer of exhaust gases from the engine cylinders to the exhaust system, ensuring optimal performance and reduced emissions.

Integration with the Exhaust Collector Mounting

The Exhaust Collector Connection interfaces directly with the Exhaust Collector Mounting. This mounting is responsible for securing the exhaust collector to the engine block. The connection ensures a tight seal, preventing any exhaust leaks that could lead to performance issues or increased emissions. The secure fit also aids in maintaining the structural integrity of the exhaust system under varying engine loads and temperatures 10.

Interaction with the Turbocharger

In turbocharged engine systems, the Exhaust Collector Connection plays a significant role in directing exhaust gases towards the turbocharger. The turbocharger relies on the momentum of these gases to spin its turbine, which in turn drives the compressor to intake more air into the engine. A well-fitted connection ensures that exhaust gases are efficiently channeled, maximizing turbocharger efficiency and overall engine performance 11.

Contribution to the Exhaust System Arrangement

The Exhaust Collector Connection is a vital component in the overall arrangement of the exhaust system. It acts as a junction point where multiple exhaust streams from different cylinders converge before being directed into the main exhaust pipe. This consolidation of exhaust flows helps in maintaining a consistent exhaust pressure, which is essential for the smooth operation of the engine. Additionally, it allows for better management of exhaust backpressure, which can influence engine performance and fuel efficiency 12.

Conclusion

In summary, the Exhaust Collector Connection (part 3088221) is a key component that ensures the efficient and reliable operation of the exhaust system by interfacing with the Exhaust Collector Mounting, aiding turbocharger function, and contributing to the overall exhaust system arrangement. Regular maintenance and proper installation are crucial to maximize its benefits and ensure the longevity of the exhaust system.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021482: Owners Manual.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021482: Owners Manual.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021482: Owners Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021482: Owners Manual.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.