This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Gas Recirculation Mixer Ejector (Part #3103459) manufactured by Cummins is a component designed to enhance the efficiency and environmental performance of commercial truck engines. This part plays a role in the Exhaust Gas Recirculation (EGR) system by facilitating the recirculation of exhaust gases back into the engine intake. Its significance lies in its ability to help reduce nitrogen oxides (NOx) emissions, contributing to both engine performance and compliance with emissions regulations 1.

Basic Concepts of Exhaust Gas Recirculation (EGR)

Exhaust Gas Recirculation (EGR) systems operate on the principle of recirculating a portion of an engine’s exhaust gas back to the engine cylinders. This process dilutes the oxygen in the intake air, which lowers the combustion temperature and reduces the formation of nitrogen oxides (NOx). By recirculating exhaust gases, EGR systems contribute to lower emissions and help engines meet stringent environmental standards 2.

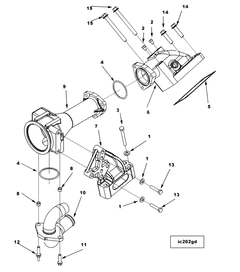

Function of the Exhaust Gas Recirculation Mixer Ejector

The Exhaust Gas Recirculation Mixer Ejector is integral to the EGR system’s operation. It mixes and ejects recirculated exhaust gases into the intake stream. This component ensures that the exhaust gases are evenly distributed and properly integrated with the fresh air intake, optimizing the EGR process. The mixer ejector’s design allows for efficient mixing, which is crucial for the effective reduction of NOx emissions 3.

Purpose and Role in Truck Operation

In the context of commercial truck engines, the Exhaust Gas Recirculation Mixer Ejector serves to enhance emissions reduction and engine performance. By facilitating the EGR process, it helps lower NOx emissions, which is particularly important for meeting regulatory standards. Additionally, the efficient recirculation of exhaust gases can contribute to improved fuel efficiency and overall engine performance.

Key Features

The Exhaust Gas Recirculation Mixer Ejector is characterized by its robust construction and precise design. It is typically made from durable materials that can withstand the high temperatures and pressures of the EGR system. Key features include its compact design, which allows for easy integration into the engine system, and its efficient mixing capabilities, which ensure optimal performance of the EGR system.

Benefits of Using the Exhaust Gas Recirculation Mixer Ejector

Incorporating the Exhaust Gas Recirculation Mixer Ejector into truck engines offers several advantages. It aids in achieving improved emissions compliance by effectively reducing NOx emissions. Additionally, the enhanced EGR process can lead to better fuel efficiency and reduced environmental impact. The mixer ejector’s reliable performance also contributes to the overall durability and efficiency of the engine.

Installation and Integration

Proper installation and integration of the Exhaust Gas Recirculation Mixer Ejector within the EGR system are vital for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the engine system. Careful attention to sealing and connections is necessary to prevent leaks and ensure the efficient operation of the EGR system.

Maintenance and Troubleshooting

Routine maintenance of the Exhaust Gas Recirculation Mixer Ejector is important for ensuring its longevity and performance. This includes regular inspections for signs of wear or damage, cleaning to remove any buildup of soot or contaminants, and ensuring all connections are secure. Troubleshooting may involve checking for proper mixing and ejection of exhaust gases, as well as verifying that the component is functioning within specified parameters.

Regulatory Compliance

The Exhaust Gas Recirculation Mixer Ejector helps commercial truck engines comply with various regulatory standards and emissions regulations. By reducing NOx emissions, it assists engines in meeting environmental regulations and industry standards. This compliance is crucial for operators to avoid penalties and maintain their vehicles’ roadworthiness in jurisdictions with strict emissions controls.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to sustainability. The company’s product offerings cater to various industries, with a strong focus on the commercial truck sector, where it provides reliable and efficient power solutions.

Exhaust Gas Recirculation Mixer Ejector in Cummins Engines

The Exhaust Gas Recirculation (EGR) Mixer Ejector, part number 3103459, is a critical component in the EGR system of various Cummins engines. This part is designed to manage the flow of exhaust gases back into the engine’s intake system, which helps reduce nitrogen oxide (NOx) emissions and improve fuel efficiency.

ISM CM570/870 Engines

In the ISM CM570/870 engines, the EGR Mixer Ejector ensures that the correct amount of exhaust gas is recirculated. This is achieved by drawing exhaust gases from the exhaust manifold and mixing them with the incoming fresh air before it enters the intake manifold. The precise control of this process is vital for maintaining optimal engine performance and meeting stringent emission standards.

ISM CM876 Engines

Similarly, in the ISM CM876 engines, the EGR Mixer Ejector plays a pivotal role in the EGR system. The design and functionality of this part are tailored to the specific requirements of the ISM CM876 engine, ensuring that the recirculation of exhaust gases is efficient and effective. This contributes to the engine’s overall efficiency and compliance with environmental regulations.

The EGR Mixer Ejector’s integration into these engines highlights Cummins’ commitment to providing reliable and environmentally friendly engine solutions. The part’s design and placement are critical for the seamless operation of the EGR system, ensuring that the engine performs optimally while minimizing its environmental impact.

Role of Part 3103459 Exhaust Gas Recirculation Mixer Ejector in Engine Systems

The Exhaust Gas Recirculation (EGR) Mixer Ejector, identified by part number 3103459, is an essential component in modern engine systems, designed to enhance efficiency and reduce emissions. Its primary function is to blend exhaust gases with the incoming air-fuel mixture before it enters the combustion chamber.

Integration with Key Components

Location

The EGR Mixer Ejector is strategically positioned within the EGR system. It is typically located between the exhaust manifold and the intake manifold. This placement ensures that the recirculated exhaust gases are effectively mixed with the fresh air intake, optimizing the combustion process.

Air Intake Connection

The EGR Mixer Ejector plays a significant role in the air intake system. It is connected to the air intake tract, allowing for the precise introduction of recirculated exhaust gases. This connection is vital for maintaining the correct air-fuel ratio, which is essential for efficient combustion and reduced nitrogen oxide (NOx) emissions. The mixer ejector ensures that the recirculated gases are thoroughly mixed with the incoming air, preventing any potential hotspots in the combustion chamber that could lead to increased emissions and decreased engine performance.

Conclusion

The Exhaust Gas Recirculation Mixer Ejector (Part #3103459) by Cummins is a vital component in the EGR system of commercial truck engines. It enhances engine efficiency, reduces NOx emissions, and ensures compliance with environmental regulations. Its robust design, precise functionality, and integration into Cummins engines underscore the company’s commitment to innovation and sustainability in engine technology.

-

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.