This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

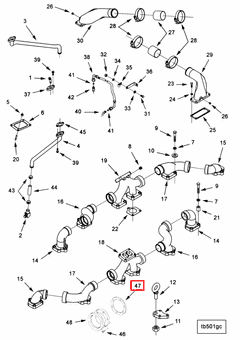

The Exhaust Outlet Connection Gasket, identified by Part #3229096, is a component manufactured by Cummins, a well-established name in the heavy-duty truck engine industry. This gasket plays a significant role in the exhaust system of heavy-duty trucks, ensuring efficient engine operation and compliance with emissions standards 1.

Basic Concepts of Exhaust Outlet Connection Gaskets

An Exhaust Outlet Connection Gasket is a sealing component positioned between the exhaust manifold and the turbocharger or exhaust pipe. Its primary function is to create a secure seal, preventing exhaust gases from escaping into the engine compartment. This seal is vital for maintaining the pressure and flow of exhaust gases, which directly impacts engine performance and emissions output 2.

Role of the Exhaust Outlet Connection Gasket in Truck Operation

The Exhaust Outlet Connection Gasket contributes to the overall operation of a truck by ensuring that exhaust gases are directed efficiently through the exhaust system. This efficient flow helps in maintaining engine efficiency by allowing the turbocharger to operate effectively, which in turn enhances the engine’s power output. Additionally, a proper seal aids in reducing emissions by preventing the escape of unburned hydrocarbons and other pollutants into the atmosphere 3.

Key Features of the Cummins Exhaust Outlet Connection Gasket

The Cummins Exhaust Outlet Connection Gasket is designed with specific features to ensure effectiveness and durability. These features include a composition of high-temperature resistant materials, a design that accommodates thermal expansion and contraction, and adherence to stringent manufacturing standards. These attributes ensure that the gasket can withstand the harsh conditions of the exhaust system while maintaining a reliable seal.

Benefits of Using the Cummins Exhaust Outlet Connection Gasket

Utilizing the Cummins Exhaust Outlet Connection Gasket offers several advantages. These include improved engine performance due to efficient exhaust gas flow, reduced emissions as a result of a secure seal, and enhanced durability that ensures long-term reliability. The gasket’s design and material composition contribute to these benefits, making it a valuable component in the exhaust system.

Installation and Maintenance

Proper installation of the Exhaust Outlet Connection Gasket is crucial for its effectiveness. It should be installed according to the manufacturer’s guidelines to ensure a proper seal. Regular maintenance checks are recommended to ensure the gasket remains in good condition. This includes inspecting for signs of wear or damage and replacing the gasket as needed to maintain engine efficiency and emissions control.

Troubleshooting Common Issues

Common issues associated with Exhaust Outlet Connection Gaskets include leaks or failures, which can lead to decreased engine performance and increased emissions. Diagnostic methods for identifying these issues include visual inspections for signs of wear or damage and pressure tests to check for leaks. Solutions may involve replacing the gasket or addressing any underlying issues that may have contributed to the failure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3229096 Exhaust Outlet Connection Gasket in Engine Systems

The Exhaust Outlet Connection Gasket, part number 3229096, is an essential component in ensuring the efficient and reliable operation of various engine systems. This gasket is specifically designed to create a secure and airtight seal between the exhaust outlet and the manifold, which is vital for maintaining the integrity of the exhaust system.

In the context of an exhaust system kit, the gasket plays a significant role by preventing exhaust leaks. When installed correctly, it ensures that exhaust gases are directed efficiently through the manifold and into the exhaust system, rather than escaping into the engine compartment. This not only enhances performance but also reduces the risk of harmful emissions entering the environment.

When integrated into a turbocharger exhaust connection, the gasket is responsible for maintaining a tight seal between the turbocharger and the exhaust manifold. This is particularly important as turbochargers operate under high pressure and temperature conditions. A well-sealed connection ensures that exhaust gases are effectively utilized to spin the turbine, thereby enhancing the turbocharger’s efficiency and the overall performance of the engine.

In the arrangement of an exhaust kit, the gasket is used at various connection points to ensure that all components, from the manifold to the muffler, are securely sealed. This is essential for maintaining the backpressure required for optimal engine performance and reducing the noise produced by the exhaust system.

For plumbing within the exhaust system, the gasket ensures that all connections are leak-free. This is important for maintaining the structural integrity of the system and ensuring that exhaust gases are channeled correctly through the muffler and out of the tailpipe.

Conclusion

In summary, the Exhaust Outlet Connection Gasket (part 3229096) is a fundamental component in the effective functioning of engine systems. Its role in creating secure, airtight seals between various exhaust components ensures efficient operation, reduces emissions, and enhances overall engine performance.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.