This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Outlet Connection 3352501, a component designed by Cummins, is integral to the operation of commercial trucks, facilitating the efficient management of exhaust gases. Cummins is renowned for its commitment to quality and innovation, providing reliable components that enhance the performance and efficiency of heavy-duty vehicles 3.

Basic Concepts of Exhaust Outlet Connections

An Exhaust Outlet Connection is a component within the exhaust system that directs exhaust gases away from the engine. Its function is vital for maintaining engine performance and efficiency, ensuring that exhaust gases are expelled smoothly and efficiently, thereby reducing backpressure 2.

Purpose of the 3352501 Exhaust Outlet Connection

This Cummins part is designed to integrate seamlessly with the exhaust system, ensuring that gases are expelled in a manner that minimizes backpressure and enhances engine performance. By facilitating the smooth flow of exhaust gases, it contributes to the overall efficiency and reliability of the truck’s engine 3.

Key Features

This part is constructed with durability and performance in mind. It is made from high-quality materials that are resistant to the high temperatures and pressures encountered in the exhaust system. Its design includes features that enhance its performance, such as precise engineering to ensure a secure fit and optimal gas flow. These characteristics contribute to its reliability and longevity in demanding commercial truck applications 1.

Benefits

The 3352501 Exhaust Outlet Connection offers several advantages. It contributes to improved engine efficiency by ensuring that exhaust gases are expelled efficiently, reducing backpressure. This can lead to enhanced engine performance and fuel efficiency. Additionally, by facilitating the smooth flow of exhaust gases, it helps in reducing emissions, contributing to a cleaner operating environment. Its durable construction ensures long-term reliability, reducing the need for frequent replacements 3.

Installation Process

Installing this part requires careful attention to detail to ensure proper fit and function. The process involves securing the connection to the exhaust system, ensuring that it is aligned correctly and tightly fastened. Tools such as wrenches and possibly a torque wrench may be required to achieve the correct tightness. Safety precautions, including wearing protective gloves and eyewear, should be observed during installation to prevent injury from hot components or sharp edges 1.

Maintenance and Care

Regular maintenance and care of the Exhaust Outlet Connection are important for ensuring optimal performance and longevity. This includes periodic inspections for signs of wear or damage, such as cracks or leaks. Cleaning the connection as part of routine maintenance can help prevent the buildup of soot or debris, which can affect its performance. Following the manufacturer’s recommendations for inspection intervals and maintenance procedures will help maintain the efficiency and reliability of the exhaust system 3.

Troubleshooting Common Issues

Common issues associated with Exhaust Outlet Connections, such as leaks or blockages, can affect the performance of the exhaust system and the engine. Troubleshooting these issues involves inspecting the connection for signs of damage or misalignment. Leaks may be addressed by tightening connections or replacing damaged gaskets, while blockages may require cleaning or, in some cases, replacement of the connection. Regular maintenance can help identify and resolve these issues before they lead to more significant problems 2.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the diesel engine industry. The company’s commitment to excellence is evident in its extensive range of products, which are designed to meet the demanding requirements of commercial and industrial applications. Cummins’ focus on research and development ensures that its products, including the 3352501 Exhaust Outlet Connection, incorporate the latest technologies and materials for optimal performance and durability 3.

Exhaust Outlet Connection Part 3352501 in Cummins Engines

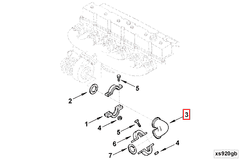

The Exhaust Outlet Connection part 3352501 is a critical component in Cummins engines, facilitating the connection between the exhaust manifold and the exhaust pipe. This part is designed to ensure a secure and efficient transfer of exhaust gases from the engine to the exhaust system, thereby maintaining optimal engine performance and reducing emissions.

Application in Cummins Engines

- 6C8.3 Engine Series: The Exhaust Outlet Connection part 3352501 is integral to the 6C8.3 engine series. This part is engineered to fit seamlessly with the exhaust manifold, ensuring a tight seal that prevents leaks and maintains the integrity of the exhaust system. Its design allows for easy installation and removal, making it a practical choice for maintenance and repairs.

The part’s compatibility with the 6C8.3 engine series underscores its importance in the overall functionality of the engine. By providing a reliable connection point, it helps to maintain the efficiency and longevity of the engine’s exhaust system 3.

Role of Part 3352501 Exhaust Outlet Connection in Engine Systems

The Exhaust Outlet Connection, identified by part number 3352501, is an essential component in the exhaust system of an engine. It serves as the interface between the exhaust manifold and the exhaust pipe, facilitating the smooth transition of exhaust gases from the engine to the exhaust system.

Integration with Engine Components

-

Exhaust Manifold: The Exhaust Outlet Connection is bolted to the exhaust manifold, which collects exhaust gases from the engine’s cylinders. This connection ensures a secure and leak-free seal, allowing the manifold to efficiently direct gases away from the engine.

-

Exhaust Pipe: Once the gases pass through the Exhaust Outlet Connection, they enter the exhaust pipe. This connection point is designed to withstand high temperatures and pressures, ensuring durability and reliability in the exhaust system.

-

Catalytic Converter: In many engine systems, the Exhaust Outlet Connection leads to the catalytic converter. This component reduces harmful emissions by converting toxic gases into less harmful substances. The connection ensures that exhaust gases flow smoothly into the converter.

-

Muffler: Following the catalytic converter, the Exhaust Outlet Connection may lead to the muffler. The muffler reduces noise levels produced by the engine. A well-fitted connection is vital for maintaining the effectiveness of the muffler in noise reduction.

-

Resonator: Some engine systems include a resonator, which further reduces exhaust noise. The Exhaust Outlet Connection plays a role in ensuring that the resonator functions correctly by providing a consistent flow of exhaust gases.

-

Tailpipe: Finally, the Exhaust Outlet Connection may also interface with the tailpipe, where exhaust gases are expelled from the vehicle. This connection must be robust to handle the varying pressures and temperatures experienced during operation.

In summary, the Exhaust Outlet Connection (part 3352501) is a key component that ensures the efficient and safe operation of the exhaust system by providing a reliable interface between various engine components 3.

Conclusion

The Exhaust Outlet Connection 3352501 is a vital component in the exhaust system of Cummins engines, ensuring efficient and safe operation by providing a reliable interface between various engine components. Its durable construction, precise engineering, and seamless integration with the exhaust system contribute to enhanced engine performance, fuel efficiency, and reduced emissions. Regular maintenance and proper installation are crucial for maintaining the efficiency and reliability of the exhaust system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.