This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Collector Connection Bracket, identified by Part #3637786, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in heavy-duty truck engines. This bracket is integral to the exhaust system, ensuring efficient operation and performance of the engine.

Function and Operation

The Exhaust Collector Connection Bracket operates within the exhaust system by collecting exhaust gases from multiple cylinders and directing them into the exhaust pipe. This process is vital for maintaining the flow of exhaust gases, ensuring they are expelled from the engine efficiently. The bracket serves as a junction point, consolidating the exhaust streams before they proceed to the exhaust pipe and eventually out of the vehicle 1.

Purpose of the Exhaust Collector Connection Bracket

In the overall operation of a truck, the Exhaust Collector Connection Bracket plays a role in efficient exhaust gas management. By effectively collecting and directing exhaust gases, it helps in reducing backpressure within the engine. This reduction in backpressure contributes to smoother engine operation and can enhance overall engine performance 2.

Key Features

The primary features of the Exhaust Collector Connection Bracket include its material construction, which is designed for durability and resistance to the high temperatures and corrosive environments typical of exhaust systems. The design considerations focus on ensuring a secure fit and integration with other exhaust system components, promoting longevity and reliable performance 3.

Benefits

The advantages provided by the Exhaust Collector Connection Bracket include improved engine performance due to efficient exhaust gas management. This efficiency can lead to enhanced fuel efficiency, as the engine operates more smoothly with reduced backpressure. Additionally, by ensuring proper exhaust flow, the bracket contributes to reduced emissions, aligning with environmental regulations and standards 4.

Installation Process

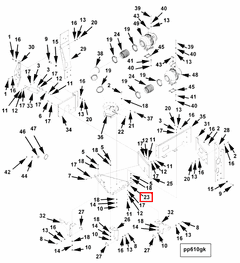

Installing the Exhaust Collector Connection Bracket involves several steps to ensure proper fit and function. Initially, the existing bracket, if present, should be removed. The new bracket should then be positioned according to the manufacturer’s guidelines, ensuring alignment with the exhaust manifold and the exhaust pipe. Secure the bracket using the specified fasteners, taking care to achieve a tight seal to prevent leaks. It is important to verify the installation by checking for proper alignment and secure fastening before operating the engine 5.

Common Issues and Troubleshooting

Typical problems associated with the Exhaust Collector Connection Bracket may include leaks or corrosion. Leaks can often be identified by unusual noises from the exhaust system or a decrease in engine performance. Corrosion may be visible as discoloration or deterioration of the bracket material. Troubleshooting these issues involves inspecting the bracket for signs of damage or wear, ensuring all fasteners are secure, and replacing the bracket if necessary to maintain system integrity.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Collector Connection Bracket, regular maintenance practices are recommended. These include periodic inspections for signs of wear, corrosion, or leaks. Cleaning the bracket and surrounding areas can prevent the buildup of debris that may contribute to corrosion. Additionally, ensuring all fasteners remain tight and secure can help maintain a proper seal and prevent exhaust leaks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. Their product range includes engines and components for on-highway and off-highway applications, demonstrating their commitment to meeting the diverse needs of their customers.

Exhaust Collector Connection Bracket for Cummins Engines

The Exhaust Collector Connection Bracket, part number 3637786, manufactured by Cummins, is a critical component in the exhaust system of several Cummins engines. This bracket is essential for maintaining the structural integrity and alignment of the exhaust collector, ensuring efficient operation and longevity of the engine.

KTA38GC Engines

In the KTA38GC series, the Exhaust Collector Connection Bracket is specifically designed to fit seamlessly with the exhaust manifold and collector. This bracket plays a pivotal role in securing the exhaust collector to the engine block, preventing any misalignment that could lead to performance issues or damage.

CM558 Engines

For the CM558 engines, the Exhaust Collector Connection Bracket is engineered to provide robust support for the exhaust collector. This bracket ensures that the exhaust collector remains firmly attached to the engine, facilitating smooth exhaust flow and reducing the risk of leaks or structural failure.

Grouping of Engines

The Exhaust Collector Connection Bracket is compatible with a range of Cummins engines, including but not limited to the KTA38GC and CM558 series. Its design is tailored to fit the specific requirements of these engines, ensuring a precise and secure fit that enhances overall engine performance and reliability.

Role of Part 3637786 Exhaust Collector Connection Bracket in Engine Systems

The Exhaust Collector Connection Bracket, identified by part number 3637786, serves as a pivotal interface in the engine system, facilitating the integration of several key components.

Integration with Accessories

This bracket is instrumental in securing various engine accessories. By providing a stable mounting point, it ensures that accessories are firmly attached and correctly aligned. This stability is essential for the efficient operation of these accessories, which may include sensors, emission control devices, or other auxiliary components that rely on precise positioning and secure attachment to function optimally.

Connection to Exhaust Outlet

The bracket plays a significant role in the exhaust system by connecting the exhaust manifold to the exhaust outlet. This connection is vital for directing exhaust gases away from the engine. The bracket’s design allows for the efficient transfer of exhaust gases, minimizing backpressure and ensuring that the exhaust system operates smoothly. This, in turn, contributes to the overall performance and efficiency of the engine.

Interaction with Turbocharger

In turbocharged engine systems, the Exhaust Collector Connection Bracket is particularly important. It helps in maintaining the structural integrity of the exhaust system, which is subjected to high temperatures and pressures due to the turbocharger’s operation. The bracket ensures that the exhaust manifold remains securely attached to the turbocharger, allowing for optimal airflow and pressure management. This is essential for the turbocharger to function effectively, enhancing engine performance and power output.

Conclusion

The Exhaust Collector Connection Bracket (part 3637786) is a key component in the engine system, facilitating the secure and efficient integration of accessories, directing exhaust gases, and supporting the operation of turbochargers. Its role in maintaining the structural and functional integrity of the engine system is indispensable.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5504185) for GTA38E G CMEICS G114 and GTA50E G CMEICS G115 Engines.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.