3642648

Exhaust Manifold

Cummins®

AVAILABLE

10 are currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3642648 Exhaust Manifold is a component designed for use in commercial trucks. It plays a role in the engine’s operation by managing the flow of exhaust gases. Understanding its function and importance can help in maintaining the efficiency and performance of the vehicle.

Basic Concepts of Exhaust Manifolds

An exhaust manifold is a part of an engine’s exhaust system that collects exhaust gases from the cylinders and directs them into the exhaust pipe. It is typically made from cast iron or stainless steel to withstand high temperatures and pressures. The manifold’s design allows it to evenly distribute exhaust gases, which helps in reducing backpressure and improving engine performance 1.

Purpose of the Cummins 3642648 Exhaust Manifold

The Cummins 3642648 Exhaust Manifold is specifically engineered to channel exhaust gases away from the engine efficiently. By doing so, it helps in maintaining the engine’s operating temperature and ensures that the exhaust system functions correctly. This component plays a role in the overall exhaust system by facilitating the smooth flow of gases from the engine to the exhaust pipe 2.

Key Features

The Cummins 3642648 Exhaust Manifold is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that offer resistance to corrosion and high temperatures. The manifold’s design includes features that enhance its performance and durability, such as precise castings and smooth internal passages for optimal gas flow 3.

Benefits

The use of the Cummins 3642648 Exhaust Manifold in a truck’s engine system can lead to several benefits. These include improved engine efficiency due to reduced backpressure, lower emissions as a result of efficient gas flow, and enhanced durability thanks to the high-quality materials and design. These factors contribute to the overall performance and longevity of the engine 4.

Installation Considerations

When installing the Cummins 3642648 Exhaust Manifold, it is important to ensure compatibility with the specific engine type. Proper fitting is crucial to avoid leaks and ensure efficient operation. Following manufacturer guidelines during installation can help in achieving the best results and maintaining the integrity of the exhaust system 5.

Common Issues and Troubleshooting

Common issues with the Cummins 3642648 Exhaust Manifold may include leaks or cracks, which can affect the performance of the exhaust system. Regular inspections can help in identifying these problems early. Troubleshooting steps may involve checking for proper installation, inspecting for damage, and ensuring that all connections are secure.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3642648 Exhaust Manifold, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning to remove any buildup that may obstruct gas flow, and ensuring that all connections are tight and secure. Adhering to these maintenance practices can help in preventing issues and maintaining the efficiency of the exhaust system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of providing reliable and high-performance engine components, Cummins has built a reputation for excellence. The company’s products, including the 3642648 Exhaust Manifold, are designed with a focus on durability, efficiency, and compatibility with a wide range of engine types.

Exhaust Manifold 3642648 Compatibility with Cummins Engines

The Exhaust Manifold part number 3642648, manufactured by Cummins, is designed to fit seamlessly with several of their high-performance engines. This part is crucial for the efficient operation of these engines, ensuring that exhaust gases are properly managed and expelled.

QSK60 Series

The QSK60 series engines are known for their robust design and high power output, making them suitable for heavy-duty applications. The Exhaust Manifold 3642648 is engineered to fit these engines, providing a reliable connection between the engine’s cylinders and the exhaust system. This ensures optimal exhaust flow, which is vital for maintaining engine performance and efficiency.

CM500 Series

The CM500 series engines are another range of Cummins engines that benefit from the Exhaust Manifold 3642648. These engines are often used in various industrial applications, where reliability and durability are paramount. The manifold’s design allows for effective heat management and pressure regulation, contributing to the overall longevity and performance of the engine.

Integration and Functionality

The Exhaust Manifold 3642648 is designed to integrate smoothly with the engine’s architecture, ensuring a secure and efficient fit. This part is critical for the exhaust system’s functionality, as it collects exhaust gases from the engine’s cylinders and directs them towards the exhaust outlet. Proper integration of this manifold is essential for maintaining the engine’s performance, reducing emissions, and ensuring longevity.

Role of Exhaust Manifold Part 3642648 in Engine Systems

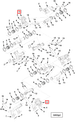

The exhaust manifold part 3642648 is a key component in the efficient operation of an engine’s exhaust system. It is responsible for collecting exhaust gases from the engine’s cylinders and directing them into the exhaust system. Here’s how it interacts with various components:

-

Cylinders: The exhaust manifold is directly connected to the engine’s cylinders. As the engine operates, exhaust gases are expelled from the cylinders and enter the manifold.

-

Exhaust Valves: These valves open to allow the exhaust gases to exit the cylinders and flow into the manifold. The design of the manifold ensures a smooth transition from the valves to the exhaust pipes.

-

Catalytic Converter: The manifold channels the exhaust gases to the catalytic converter, where harmful emissions are converted into less harmful substances. This process is essential for meeting environmental regulations.

-

Exhaust Pipes: After passing through the catalytic converter, the gases travel through the exhaust pipes. The manifold’s design helps maintain consistent flow, reducing backpressure and improving engine performance.

-

Muffler: The manifold also plays a role in directing exhaust gases to the muffler, where noise is reduced. Efficient manifold design contributes to a quieter and more pleasant driving experience.

-

Turbocharger (if present): In turbocharged engines, the manifold is connected to the turbocharger. It helps in channeling exhaust gases to spin the turbine, which in turn compresses the intake air, boosting engine power.

-

Oxygen Sensors: These sensors are often placed near the manifold to monitor the exhaust gas composition. Accurate readings from these sensors help the engine control unit (ECU) adjust the air-fuel mixture for optimal performance and emissions.

-

Heat Shields: The manifold can get extremely hot during operation. Heat shields are often installed to protect nearby components and the vehicle’s undercarriage from excessive heat.

In summary, the exhaust manifold part 3642648 is integral to the efficient and effective operation of the engine’s exhaust system, ensuring smooth flow of exhaust gases and contributing to overall engine performance and emissions control.

Conclusion

The Cummins 3642648 Exhaust Manifold is a critical component in the exhaust system of commercial trucks, designed to enhance engine performance, efficiency, and durability. Its robust construction, compatibility with various Cummins engines, and role in managing exhaust gases make it an essential part for maintaining the overall health and performance of the vehicle’s engine system.

-

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4332696.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.