This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

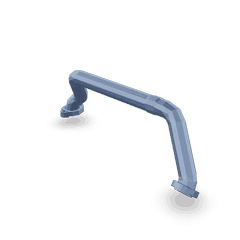

The Exhaust Transfer Tube, part number 3687052, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industries. This part is essential for the exhaust system of heavy-duty trucks, enhancing the vehicle’s efficiency and performance.

Function and Operation

The Exhaust Transfer Tube directs exhaust gases from the engine to the exhaust system. It ensures efficient gas channeling, minimizing backpressure that could hinder engine performance. Designed to withstand high temperatures and pressures, this Cummins part guarantees reliable operation under various driving conditions 1.

Purpose of the Exhaust Transfer Tube

In truck operations, the Exhaust Transfer Tube facilitates the smooth transfer of exhaust gases, contributing to emission control by ensuring proper gas direction through the exhaust system. This allows for effective treatment to reduce harmful emissions. Additionally, by maintaining efficient exhaust flow, the tube supports optimal engine performance 2.

Key Features

The Exhaust Transfer Tube is constructed from durable materials resistant to corrosion and high temperatures. Its design may include specific contours or connections for a secure fit within the exhaust system. Unique attributes, such as reinforced sections or specialized coatings, enhance its durability and performance 3.

Benefits

The Exhaust Transfer Tube offers benefits such as improved exhaust flow, leading to reduced backpressure within the system. This may contribute to increased fuel efficiency and engine performance. By ensuring efficient gas direction and treatment, the tube aids in maintaining compliance with emission standards.

Installation and Integration

Proper installation of the Exhaust Transfer Tube involves following manufacturer guidelines, including ensuring the exhaust system is clean and free from obstructions. Careful attention to fitment and securing the tube is necessary to maintain the exhaust system’s integrity.

Maintenance and Care

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Exhaust Transfer Tube. Regular inspection intervals to check for wear, corrosion, or damage, and cleaning procedures as specified by the manufacturer, can help maintain the tube’s efficiency and prevent buildup that could impede exhaust flow.

Troubleshooting Common Issues

Common issues with the Exhaust Transfer Tube may include leaks or blockages within the system. Diagnostic steps to identify these issues may involve visual inspections or pressure tests to locate the source of the problem. Repair solutions could range from tightening connections to replacing damaged sections of the tube, depending on the nature of the issue.

Environmental Impact

The use of the Exhaust Transfer Tube contributes to reduced emissions and improved air quality in heavy-duty truck operations. By ensuring efficient exhaust flow and treatment, the tube minimizes the environmental impact of truck emissions, supporting efforts to maintain cleaner air quality in operating environments.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industries, known for its innovation and quality. The company’s product portfolio includes a wide range of components and systems designed to enhance vehicle performance and efficiency. Cummins is recognized for its commitment to quality and its contributions to advancing technology in the industry.

Conclusion

The Exhaust Transfer Tube, part number 3687052, plays a vital role in the exhaust systems of heavy-duty trucks, contributing to engine efficiency, performance, and emission control. Its design and functionality are critical for maintaining the balance between engine performance and environmental compliance in modern engine design.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.