This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Gas Recirculation (EGR) Cooler is a component designed to enhance the efficiency and environmental performance of diesel engines. It plays a role in emissions control by managing the temperature of recirculated exhaust gases. This overview will explore the EGR Cooler’s function, its integration into the EGR system, and its importance in modern diesel engine technology.

Basic Concepts of Exhaust Gas Recirculation Cooler

The EGR system is integral to diesel engine operation, designed to reduce nitrogen oxides (NOx) emissions. It functions by recirculating a portion of the exhaust gas back into the intake stream. The EGR cooler is a component within this system, tasked with cooling the recirculated exhaust gases before they mix with the fresh air entering the engine. This cooling process lowers the temperature of the intake charge, which helps in reducing NOx formation during combustion 1.

Purpose of the 3687813 Exhaust Gas Recirculation Cooler

The 3687813 EGR Cooler is engineered to support the EGR system in diesel engines by cooling the recirculated exhaust gases. By reducing the temperature of these gases before they enter the intake manifold, the cooler aids in lowering NOx emissions. This process not only enhances emissions performance but also contributes to the overall efficiency and durability of the engine 2.

Key Features

The 3687813 EGR Cooler is constructed with high-quality materials to ensure durability and efficiency. Its design incorporates advanced cooling technologies to maximize heat exchange between the exhaust gases and the coolant. Unique design aspects, such as optimized flow paths and robust construction, enhance its performance and longevity, making it a reliable component in the EGR system.

Benefits

Utilizing the 3687813 EGR Cooler offers several advantages, including improved emissions performance, enhanced engine efficiency, and compliance with environmental regulations. By effectively reducing NOx emissions, the cooler contributes to a cleaner environment. Additionally, it supports overall engine health and longevity by maintaining optimal operating temperatures and reducing thermal stress on engine components 3.

Installation and Integration

Proper installation of the 3687813 EGR Cooler is vital for its effective operation within the EGR system. It should be correctly positioned and connected to ensure seamless integration with other components. Attention to detail during installation helps maintain the system’s efficiency and reliability, underscoring the importance of following manufacturer guidelines for placement and connection.

Troubleshooting and Maintenance

Common issues with EGR coolers include clogging, corrosion, and leaks. Regular inspection and maintenance are recommended to ensure the 3687813 EGR Cooler operates efficiently. Maintenance tips include cleaning the cooler to remove deposits, checking for signs of corrosion or damage, and adhering to recommended replacement schedules to prevent performance degradation.

Performance and Efficiency

The 3687813 EGR Cooler plays a role in enhancing the performance and efficiency of the truck’s engine. By effectively cooling the recirculated exhaust gases, it contributes to improved fuel economy, power output, and emissions reductions. The cooler’s impact on engine performance underscores its value in modern diesel engine technology.

Environmental Impact

The use of an EGR cooler, such as the 3687813, significantly reduces harmful emissions from diesel engines. By lowering NOx emissions, it helps in complying with environmental standards and contributes to a reduction in the overall environmental footprint of diesel-powered vehicles.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history in the automotive and heavy-duty truck industries, Cummins is committed to innovation, quality, and environmental responsibility. The company’s products, including the 3687813 EGR Cooler, reflect its dedication to advancing technology and sustainability in the power industry.

Exhaust Gas Recirculation Cooler (Part 3687813) Compatibility with Cummins Engines

The Exhaust Gas Recirculation (EGR) Cooler, identified by part number 3687813, is a component in the EGR system of various Cummins engines. This cooler is designed to manage the temperature of exhaust gases before they are reintroduced into the engine’s intake system, thereby aiding in the reduction of nitrogen oxide (NOx) emissions.

ISX15 Series

- ISX15 CM2250: The EGR cooler is compatible with this engine model, ensuring efficient EGR operation and contributing to the engine’s overall emission control.

- ISX15 CM2350 X101: This variant also utilizes the EGR cooler, maintaining the same emission control standards as the CM2250 model.

QSX15 Series

- QSX15 CM2250: The EGR cooler is designed to fit seamlessly with this engine, providing the necessary cooling for the recirculated exhaust gases.

- QSX15 CM2250 ECF: This model includes the EGR cooler as part of its emission control system, ensuring compliance with environmental regulations.

- QSX15 CM2350 X105: Similar to its counterparts, this engine model incorporates the EGR cooler to manage exhaust gas temperatures effectively.

The EGR cooler’s design and functionality are consistent across these engine models, ensuring that each engine can benefit from reduced emissions and improved efficiency.

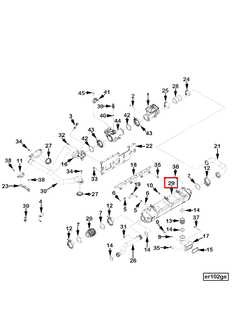

Understanding the Integration of Part 3687813 Exhaust Gas Recirculation Cooler in Engine Systems

The Exhaust Gas Recirculation (EGR) Cooler, identified by part number 3687813, is a pivotal component within the EGR system, designed to enhance engine performance and reduce emissions. Its integration with other components facilitates a more efficient and environmentally friendly operation of the engine.

Role in the EGR Cooler Kit

When incorporated into an EGR Cooler Kit, part 3687813 works in conjunction with other components to cool the recirculated exhaust gases before they are reintroduced into the intake manifold. This cooling process is essential for reducing the temperature of the exhaust gases, which in turn lowers the combustion temperature in the cylinders. As a result, the formation of nitrogen oxides (NOx) is minimized, contributing to a cleaner exhaust output.

Interaction with Exhaust Recirculation System

Within the Exhaust Recirculation (EGR) system, the EGR Cooler plays a significant role in managing the temperature of the recirculated gases. By cooling these gases, the EGR Cooler helps maintain optimal engine operating conditions. This temperature regulation is vital for ensuring that the EGR valve and other components within the EGR system function efficiently. The cooled gases also help in diluting the intake charge, which is a key strategy in reducing NOx emissions.

Contribution to Exhaust Recirculation Air Arrangement

The Exhaust Recirculation Air Arrangement benefits significantly from the presence of the EGR Cooler. This arrangement is designed to mix the cooled exhaust gases with the incoming air before it enters the combustion chamber. The EGR Cooler ensures that the gases are at the right temperature, which is crucial for the effective operation of this arrangement. Proper temperature control of the recirculated gases ensures that the air-fuel mixture is optimal, leading to improved engine efficiency and reduced emissions.

Conclusion

In summary, the 3687813 Exhaust Gas Recirculation Cooler is integral to the functioning of the EGR system. Its role in cooling the recirculated exhaust gases not only enhances engine performance but also plays a significant part in emission reduction strategies employed in modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.