This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

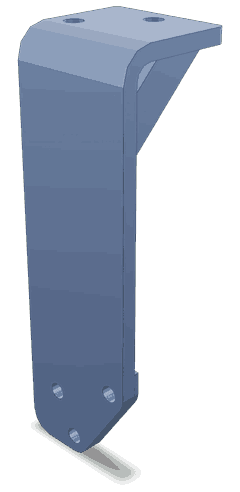

The Exhaust Connection Bracket Assembly, identified by part number 3866500, is a component manufactured by Cummins, a well-established leader in the automotive and heavy-duty truck industry. This assembly is designed to play a significant role in the exhaust system of heavy-duty trucks, ensuring the secure and proper alignment of exhaust components.

Purpose and Function

The Exhaust Connection Bracket Assembly serves to anchor and align various components within the exhaust system of a truck. By providing a stable connection point, it ensures that the exhaust components remain in the correct position, which is vital for the efficient operation of the exhaust system. This assembly helps in maintaining the structural integrity of the exhaust system, allowing for optimal performance and reduced emissions 1.

Key Features

The design of the Exhaust Connection Bracket Assembly incorporates several important characteristics. It is constructed from high-quality materials that offer durability and resistance to corrosion, ensuring longevity even in harsh operating environments. The assembly is specifically engineered to be compatible with Cummins engines, ensuring a precise fit and reliable performance. Its robust construction is capable of withstanding the high temperatures and pressures associated with exhaust systems 2.

Benefits

Incorporating the Exhaust Connection Bracket Assembly into a truck’s exhaust system offers several advantages. It enhances the overall integrity of the exhaust system by providing a secure connection for components, which helps in reducing vibrations that can lead to wear and tear. Additionally, the assembly contributes to the improved performance and reliability of the truck by ensuring that the exhaust system operates efficiently. This can lead to better fuel efficiency and reduced maintenance costs over time 3.

Installation Process

Installing the Exhaust Connection Bracket Assembly requires careful attention to detail. The process involves securing the bracket to the appropriate mounting points on the truck’s frame and then attaching the exhaust components to the bracket. It is important to use the correct tools for the job, such as wrenches and socket sets, to ensure that all connections are tight and secure. Precautions should be taken to avoid over-tightening, which can damage the components or the bracket itself 4.

Maintenance and Troubleshooting

Regular inspection of the Exhaust Connection Bracket Assembly is recommended to ensure its continued effectiveness. Look for signs of wear, corrosion, or loose connections. Common issues may include corrosion due to exposure to the elements or vibrations causing components to become misaligned. If any issues are detected, it is advisable to address them promptly to prevent further damage. Troubleshooting steps may involve tightening loose connections or, in more severe cases, replacing damaged components.

Safety Considerations

When working with the Exhaust Connection Bracket Assembly, it is important to follow safety guidelines to protect oneself and ensure the job is done correctly. This includes wearing appropriate protective equipment, such as gloves and safety glasses, to guard against injuries from sharp edges or hot components. Awareness of the high temperatures associated with exhaust systems is crucial, and care should be taken to avoid burns or other heat-related injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the automotive industry. The company’s product range extends beyond engines to include aftermarket parts, power systems, and services, making it a comprehensive provider of power solutions for various applications.

Exhaust Connection Bracket Assembly for Cummins Engines

The Exhaust Connection Bracket Assembly, part number 3866500, is a critical component in the Cummins engine lineup. This part is designed to securely attach the exhaust system to the engine, ensuring a stable and leak-free connection.

K38 Engines

For the K38 engine series, the Exhaust Connection Bracket Assembly plays a pivotal role in maintaining the integrity of the exhaust system. This assembly is engineered to withstand the high temperatures and pressures associated with the exhaust system, ensuring durability and reliability.

The K38 engines, known for their robust performance, benefit from the precise fit and function of the 3866500 bracket. This part ensures that the exhaust system remains properly aligned and securely fastened, which is essential for optimal engine performance and longevity.

Grouping of Engines

In the broader context of Cummins engine families, the Exhaust Connection Bracket Assembly is a common component across various engine models. Its design and functionality are tailored to meet the specific needs of each engine series, ensuring compatibility and performance.

The 3866500 bracket is a testament to Cummins’ commitment to quality and precision engineering. Its application across different engine models underscores the importance of standardized components in maintaining engine efficiency and reliability.

Role of Part 3866500 Exhaust Connection Bracket Assembly in Engine Systems

The Exhaust Connection Bracket Assembly, identified by part number 3866500, serves as a pivotal component in the integration of various exhaust system elements within an engine setup. This assembly is instrumental in securing and aligning the exhaust outlet with the exhaust collector bracket, ensuring a seamless and efficient flow of exhaust gases from the engine.

When installed, the 3866500 assembly facilitates a robust connection between the exhaust outlet and the exhaust collector bracket. This connection is essential for maintaining the structural integrity of the exhaust system, allowing it to withstand the high temperatures and pressures generated during engine operation.

Moreover, the assembly plays a significant role in reducing vibrations and minimizing the risk of leaks within the exhaust system. By providing a stable mounting point for the exhaust components, it ensures that the exhaust gases are directed away from the engine compartment effectively, contributing to the overall performance and longevity of the engine system.

Conclusion

In summary, the 3866500 Exhaust Connection Bracket Assembly is a key component in the exhaust system, facilitating a secure and efficient connection between critical exhaust components. Its proper installation and maintenance are essential for the optimal functioning of the engine’s exhaust system.

-

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Hilgers, Michael and Achenbach, Wilfried. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.