This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

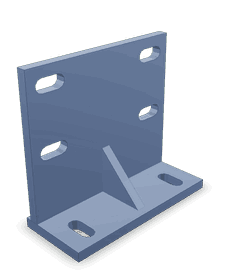

The Exhaust Connection Bracket 3897186, manufactured by Cummins, is a component designed for use in commercial truck exhaust systems. Cummins, a well-established name in the automotive and commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part is significant in the context of commercial truck operations as it plays a role in securing and aligning exhaust components, which is vital for the overall performance and emissions control of the vehicle 2.

Basic Concepts

Exhaust connection brackets are integral to the functionality of an exhaust system. They serve to connect various components of the exhaust system, ensuring that they are properly aligned and secured. This alignment and security are important for the efficient flow of exhaust gases away from the engine, reducing backpressure, and enhancing engine performance 1. Additionally, proper exhaust system alignment contributes to the reduction of emissions, as it ensures that the gases are directed through the catalytic converter and other emission control devices effectively 2.

Purpose and Function

The Exhaust Connection Bracket 3897186 is specifically designed to secure and align exhaust components in a truck’s exhaust system. By maintaining the correct positioning of these components, the bracket helps ensure that exhaust gases flow smoothly from the engine to the tailpipe. This smooth flow is important for minimizing backpressure, which can otherwise reduce engine efficiency and performance. Additionally, the bracket contributes to the structural integrity of the exhaust system, helping to prevent leaks and ensuring that the system operates within designed parameters 3.

Key Features

The Exhaust Connection Bracket 3897186 is constructed from high-quality materials that offer durability and resistance to the harsh conditions found in commercial truck exhaust systems. Its design includes features that enhance its performance and longevity, such as corrosion-resistant coatings and robust mounting points. These features ensure that the bracket can withstand the high temperatures and vibrations associated with truck operations, providing reliable service over the vehicle’s lifespan.

Benefits

Using the Exhaust Connection Bracket 3897186 offers several benefits. It contributes to improved exhaust system efficiency by ensuring that components are properly aligned and secured. This alignment helps reduce backpressure, which can enhance engine performance. Additionally, a well-maintained exhaust system with properly aligned components can lead to reduced emissions, as exhaust gases are more effectively directed through emission control devices. Overall, the use of this bracket can enhance the performance and reliability of a truck’s exhaust system 2.

Installation and Compatibility

Proper installation of the Exhaust Connection Bracket 3897186 is important for ensuring its effectiveness and the overall performance of the exhaust system. Installation guidelines should be followed to ensure that the bracket is correctly positioned and secured. Compatibility with various truck models and exhaust system configurations should be considered to ensure optimal performance and integration within the system.

Maintenance and Troubleshooting

Regular maintenance of the Exhaust Connection Bracket 3897186 is important for ensuring its continued performance and durability. This includes regular inspection for signs of wear, corrosion, or loose connections. Cleaning the bracket and surrounding components can help prevent the buildup of debris that could affect performance. Addressing common issues such as corrosion or loose connections promptly can help maintain the efficiency and reliability of the exhaust system.

Safety Considerations

When working with exhaust systems and components, including the Exhaust Connection Bracket 3897186, it is important to follow safety precautions and best practices. This includes proper handling of components, use of protective equipment, and adherence to manufacturer guidelines. Exhaust systems operate at high temperatures, and components may be hot to the touch, so caution should be exercised to avoid burns or injuries.

Environmental Impact

Exhaust systems play a role in the environmental impact of commercial trucking operations. Components like the Exhaust Connection Bracket 3897186 contribute to reducing emissions by ensuring that exhaust gases are effectively directed through emission control devices. This helps minimize the release of pollutants into the atmosphere, promoting sustainability in commercial trucking operations 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and commercial truck industry. The company’s product offerings include a wide range of parts and systems designed to enhance the performance, efficiency, and reliability of heavy-duty vehicles.

Cummins Exhaust Connection Bracket 3897186 Compatibility

The Cummins Exhaust Connection Bracket, part number 3897186, is a critical component in the engine’s exhaust system, ensuring that the exhaust manifold is securely attached to the engine block. This bracket is designed to withstand the high temperatures and pressures inherent in the exhaust system, providing durability and reliability.

K50 Series

The K50 series engines, known for their robust performance and efficiency, integrate the Exhaust Connection Bracket 3897186 seamlessly. This bracket is engineered to fit precisely with the K50 engines, ensuring a tight seal and minimizing the risk of exhaust leaks. The design of the bracket allows for easy installation and maintenance, making it a preferred choice for both original equipment manufacturers (OEM) and aftermarket applications.

K50-C Series

Similar to the K50 series, the K50-C engines also benefit from the use of the Exhaust Connection Bracket 3897186. This bracket is specifically tailored to the K50-C’s unique design, ensuring optimal performance and longevity. The bracket’s robust construction and precise fitment make it an essential part of the exhaust system, contributing to the overall efficiency and reliability of the engine.

K50-G Series

The K50-G engines, which are designed for heavy-duty applications, also utilize the Exhaust Connection Bracket 3897186. This bracket is critical in maintaining the structural integrity of the exhaust system under extreme conditions. Its design ensures that the exhaust manifold remains securely attached to the engine block, even under the most demanding operating conditions.

K50-H Series

For the K50-H engines, the Exhaust Connection Bracket 3897186 plays a vital role in the exhaust system’s functionality. This bracket is engineered to fit the specific design of the K50-H engines, ensuring a secure and reliable connection between the exhaust manifold and the engine block. Its durability and precision make it an ideal choice for applications requiring high performance and reliability.

K50-M Series

The K50-M engines, known for their versatility and efficiency, also incorporate the Exhaust Connection Bracket 3897186. This bracket is designed to fit the K50-M engines perfectly, ensuring that the exhaust manifold is securely attached to the engine block. Its robust construction and precise fitment contribute to the overall performance and longevity of the engine.

K50-P Series

In the K50-P engines, the Exhaust Connection Bracket 3897186 is a crucial component that ensures the exhaust manifold is securely attached to the engine block. This bracket is engineered to withstand the high temperatures and pressures of the exhaust system, providing durability and reliability. Its precise fitment and robust design make it an essential part of the exhaust system, contributing to the engine’s overall performance and efficiency.

Role of Part 3897186 Exhaust Connection Bracket in Engine Systems

The Exhaust Connection Bracket, identified by part number 3897186, serves as a pivotal component in the assembly and functionality of engine systems. This bracket is instrumental in securely attaching the exhaust connection to the exhaust outlet.

When integrating this bracket into an engine system, it ensures a stable and reliable connection between the exhaust components. The bracket’s design allows for precise alignment and attachment, which is essential for maintaining the integrity of the exhaust system.

In operation, the Exhaust Connection Bracket supports the exhaust connection, distributing the stresses and vibrations generated during engine operation. This support helps in preventing potential leaks and ensuring that the exhaust gases are efficiently channeled away from the engine.

Additionally, the bracket plays a role in facilitating the maintenance and repair of the exhaust system. By providing a secure mounting point, it allows for easier access to the exhaust components, simplifying the process of inspection, replacement, or adjustment.

Overall, the Exhaust Connection Bracket is a fundamental element in the exhaust system, contributing to the overall performance and durability of the engine 3.

Conclusion

The Exhaust Connection Bracket 3897186 is a critical component in the exhaust systems of commercial trucks, particularly those equipped with Cummins engines. Its role in securing and aligning exhaust components ensures efficient exhaust gas flow, reduces backpressure, and contributes to lower emissions. The bracket’s durable construction and precise fitment across various Cummins engine series underscore its importance in maintaining the performance and reliability of heavy-duty vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the longevity and efficiency of the exhaust system.

-

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing Limited, 2011.

↩ -

Addy Majewski and Hannu Jaskelainen, Diesel Emissions and Their Control: Second Edition, SAE International, 2023.

↩ ↩ ↩ ↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak, Critical Component Wear in Heavy Duty Engines, John Wiley & Sons, 2011.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.