3904986

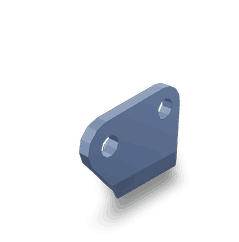

Exhaust Outlet Connection Brace

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Outlet Connection Brace, identified by Cummins Part #3904986, is a critical component designed for heavy-duty truck engines. Manufactured by Cummins Inc., a leader in the automotive and heavy-duty truck industry, this brace is integral to the exhaust system’s functionality and durability 1.

Function and Operation

The Exhaust Outlet Connection Brace operates within the exhaust system by providing structural support to the exhaust outlet. It maintains the integrity of the exhaust system under various operational stresses, such as vibrations and thermal expansion 2. Additionally, it facilitates efficient exhaust flow by ensuring the exhaust outlet remains properly aligned and sealed, which contributes to the overall performance of the engine.

Purpose of the Exhaust Outlet Connection Brace

The primary role of this Cummins part in a truck’s operation is to enhance engine performance and emissions control. By securing the exhaust outlet, it helps maintain optimal exhaust flow, which is vital for efficient engine operation. Furthermore, it contributes to emissions control by ensuring that exhaust gases are directed through the system as intended, minimizing the risk of leaks that could lead to increased emissions 3.

Key Features

The Exhaust Outlet Connection Brace is characterized by several key features that enhance its functionality. It is typically made from durable materials that can withstand high temperatures and mechanical stress. The design includes elements that allow for easy installation and integration with the exhaust system. Unique characteristics may include corrosion-resistant coatings or specialized mounting brackets that ensure a secure fit 4.

Benefits

The advantages provided by the Exhaust Outlet Connection Brace include improved durability of the exhaust system, enhanced performance due to efficient exhaust flow, and potential cost savings for fleet operators. Its robust construction and design contribute to a longer service life, reducing the frequency of replacements and repairs. Moreover, by ensuring efficient exhaust flow, it supports overall engine performance, which can lead to better fuel efficiency and reduced maintenance costs.

Installation Considerations

Proper installation of the Exhaust Outlet Connection Brace involves several steps to ensure a secure and effective fit. Prerequisites may include ensuring the exhaust system is clean and free of debris. Tools required could include wrenches, torque wrenches, and possibly a heat gun for certain applications. The installation process should follow manufacturer guidelines to ensure that the brace is properly aligned and tightened to the specified torque settings.

Maintenance and Troubleshooting

Routine maintenance practices for the Exhaust Outlet Connection Brace include regular inspections for signs of wear, corrosion, or damage. Cleaning the brace and surrounding areas can help prevent buildup that might affect performance. Common issues that may arise include loosening of the brace or damage from exposure to extreme conditions. Recommended troubleshooting steps involve re-tightening or replacing the brace as necessary, following manufacturer guidelines for maintenance and repair.

Safety Precautions

When working with the Exhaust Outlet Connection Brace, it is important to observe several safety measures. These include wearing appropriate protective equipment such as gloves and safety glasses. Handling procedures should involve careful manipulation to avoid injury from sharp edges or hot surfaces. Environmental considerations include proper disposal of any waste materials generated during installation or maintenance, in accordance with local regulations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Its product portfolio includes a variety of components and systems designed to enhance the performance, efficiency, and durability of vehicles.

Cummins Exhaust Outlet Connection Brace (Part 3904986) Compatibility

The Exhaust Outlet Connection Brace, identified by the part number 3904986, is a critical component designed to secure the exhaust system’s outlet connection. This part ensures the structural integrity and alignment of the exhaust system, preventing undue stress and potential damage to the exhaust components.

Engine Compatibility

The Exhaust Outlet Connection Brace is compatible with several Cummins engine models. Below is a list of engines where this part is applicable:

- 4B3.9

- Other Cummins Engines

This brace is engineered to fit seamlessly with the exhaust system of these engines, providing a robust connection point that maintains the alignment and stability of the exhaust outlet. It is essential for ensuring the longevity and efficiency of the exhaust system, as it helps to mitigate vibrations and stresses that could otherwise lead to system failure.

The design of the Exhaust Outlet Connection Brace is such that it can be easily installed and removed, making it convenient for maintenance and repairs. Its compatibility with multiple engine models underscores its versatility and importance in maintaining the exhaust system’s integrity across different engine configurations.

Role of Part 3904986 Exhaust Outlet Connection Brace in Engine Systems

The Exhaust Outlet Connection Brace, identified by part number 3904986, serves as a pivotal component in the integration and stabilization of the exhaust system within various engine configurations. This brace is engineered to connect the exhaust outlet to the engine’s exhaust manifold or turbocharger, ensuring a secure and vibration-resistant attachment.

In turbocharged engine systems, the brace plays a significant role in maintaining the integrity of the exhaust flow from the turbocharger to the exhaust manifold. It helps in reducing the stress on the exhaust manifold caused by the high-pressure exhaust gases expelled from the turbocharger. This reduction in stress contributes to the longevity and reliability of the turbocharger and manifold assembly.

For engines equipped with catalytic converters, the Exhaust Outlet Connection Brace ensures a stable connection between the exhaust manifold and the catalytic converter. This stability is essential for the efficient operation of the catalytic converter, as any movement or misalignment can lead to decreased performance and increased emissions.

In engines with after-treatment systems, such as Diesel Particulate Filters (DPF) or Selective Catalytic Reduction (SCR) systems, the brace facilitates a secure connection between the exhaust manifold and these components. This secure attachment is vital for the proper functioning of the after-treatment systems, ensuring that exhaust gases are effectively treated before being released into the atmosphere.

Overall, the Exhaust Outlet Connection Brace (part 3904986) is instrumental in providing a robust and reliable connection within the exhaust system, enhancing the performance and durability of the engine’s exhaust components.

Conclusion

The Exhaust Outlet Connection Brace (Cummins Part #3904986) is a vital component in the exhaust systems of heavy-duty truck engines. Its role in providing structural support, ensuring efficient exhaust flow, and contributing to emissions control underscores its importance in maintaining engine performance and durability. Proper installation, maintenance, and adherence to safety precautions are essential for maximizing the benefits of this part.

-

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023.

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021.

↩ -

Entire Vehicle: Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.